Measuring method of low-concentration odorous gas

A malodorous gas and measurement method technology, which is used in the odor concentration test of low-concentration malodorous gas, and the measurement field of low-concentration malodorous gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

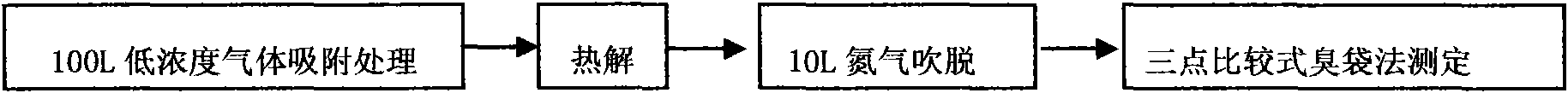

[0022] Such as figure 1 Shown low-concentration malodorous gas measuring method, it comprises the steps:

[0023] (1) Adsorption treatment:

[0024] At a normal temperature of 20°C, quantitatively pass 100L of malodorous gas into a glass tube filled with solid Tenax poly-2,6-diphenyl-p-phenylene ether and activated carbon through a flow measuring device. The length of the concentrating tube is about 10cm, pipe diameter 1cm, (poly-2,6-diphenylphenyl ether:activated carbon volume ratio is 1:1), completely adsorb the malodorous substance contained in the malodorous gas, and the adsorption time is 20min. The flow rate is 5L / min, and the treated gas flows out from the other end.

[0025] (2) thermal analysis treatment:

[0026] Heat the glass tube in the first step to 120°C to desorb the malodorous substances adsorbed on the solid adsorbent, and then desorb the malodorous substances adsorbed for 2 minutes.

[0027] (3) Stripping treatment:

[0028] Through the flow measuring d...

Embodiment 2

[0030] (1) Adsorption treatment:

[0031] At a normal temperature of 25°C, through a flow measuring device, quantitatively pass 100L of malodorous gas into a glass tube filled with solid Tenax poly-2,6-diphenyl-p-phenylene ether and activated carbon. The length of the concentrating tube is 10 cm. , diameter 1cm, (poly 2,6-diphenylphenyl ether: activated carbon weight ratio is 1: 1.5), completely absorb the malodorous substances contained in the malodorous gas, and the treated gas flows out from the other end. The adsorption time is about 10min, and the flow rate is 10L / min.

[0032] (2) thermal analysis treatment:

[0033] Heat the glass tube in the first step to a specific temperature, such as 140°C, to desorb the malodorous substances adsorbed on the solid adsorbent, and then desorb the malodorous substances adsorbed. The adsorption time is 3min.

[0034] (3) Stripping treatment:

[0035] Through the flow measuring device, quantitatively pass 10L N into the glass tube 2...

Embodiment 3

[0037] Application Test Description:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com