Disc brake motor for rotary whirley

A technology of disc brakes and jib cranes, which is applied in the direction of controlling mechanical energy, electrical components, and electromechanical devices, and can solve the problems of installation structure volume, large weight, large axial and radial dimensions, and large occupied space. To achieve the effect of simplified structure, short axial dimension and flexible braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

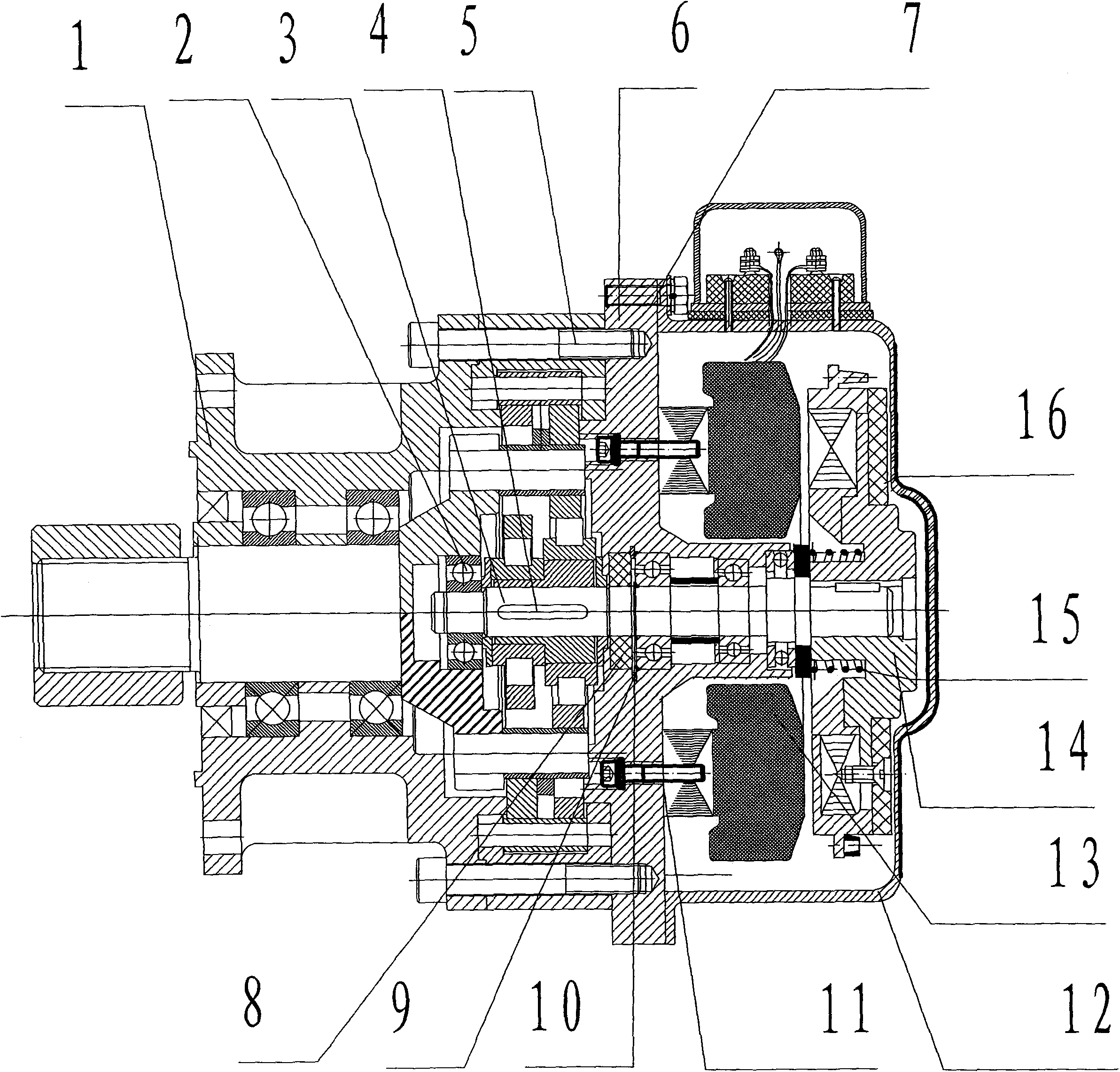

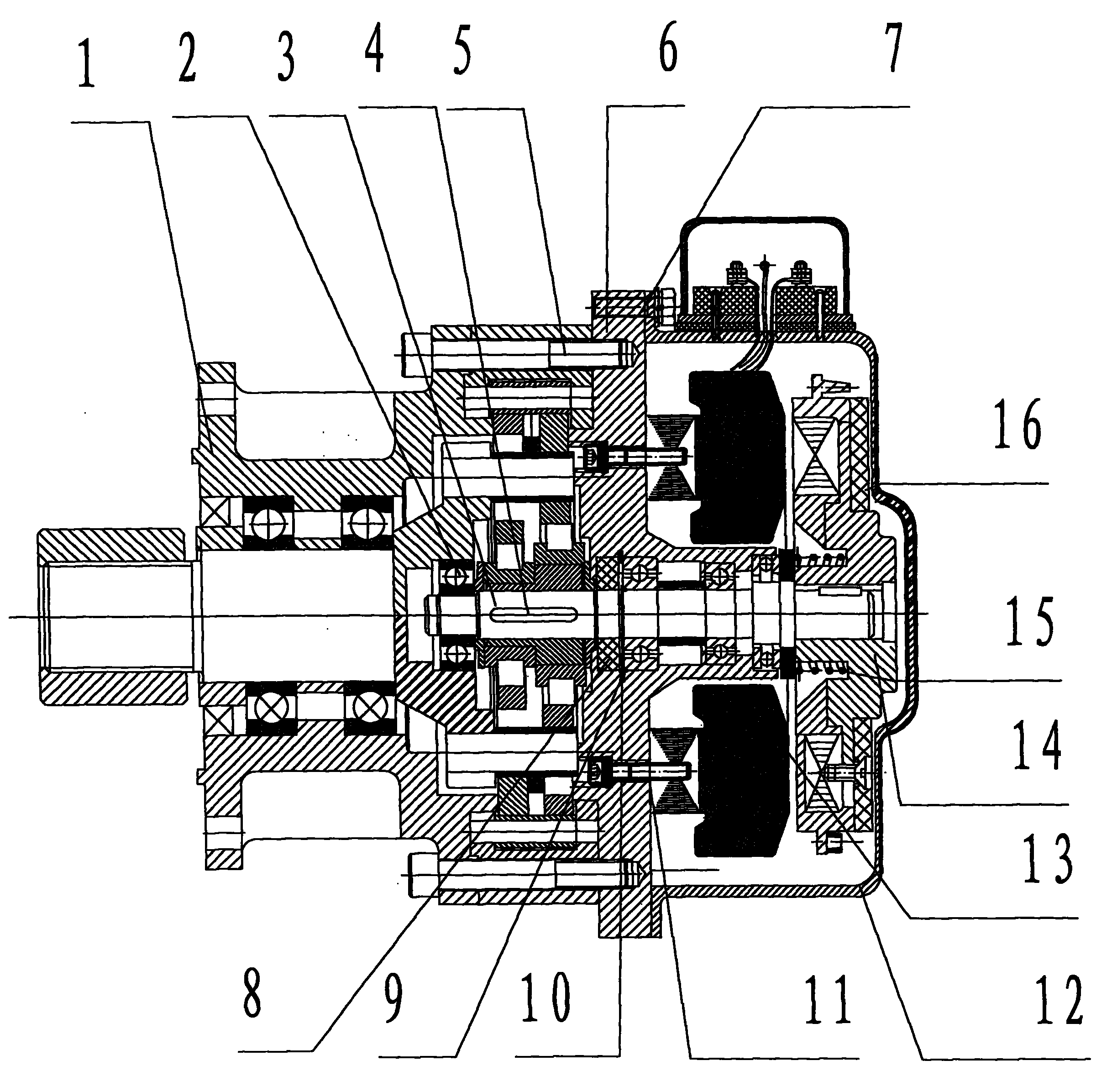

[0012] The schematic cross-sectional view of the YHHP1100 disc brake motor used in the slewing jib crane of the present invention will be described below in conjunction with the accompanying drawings.

[0013] The motor stator 13 and the rotor 14 are in the shape of a disk, and the planar coils are embedded in the slot of the stator core to form the stator winding. The back of the rotor 14 is bonded with a ring-shaped non-asbestos brake pad 16 to form a whole, and the compression spring 15 is installed on the iron core of the rotor 14. In the central groove, the motor casing 12 is connected with the motor frame 6 with the M8×35 hexagonal connection screw 7, covers the stator 13 rotor 14 and maintains a brake clearance with the annular non-asbestos brake pad 16. The motor stator 13 and the motor frame 6 are connected by M8×18 hexagon socket head screws 11, and sealed with HZ703 adhesive sealant to prevent lubricating oil from entering the motor, and evenly apply calcium-based lu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com