Photovoltaic assembly junction box

A photovoltaic module and junction box technology, applied in photovoltaic modules, photovoltaic power generation, electrical components, etc., can solve the problems of burnt-out components, urgent demand for junction boxes, and failure of sealing performance, so as to enhance the heat dissipation capacity and solve the problem that the power cannot be increased , The effect of solving the sealing problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

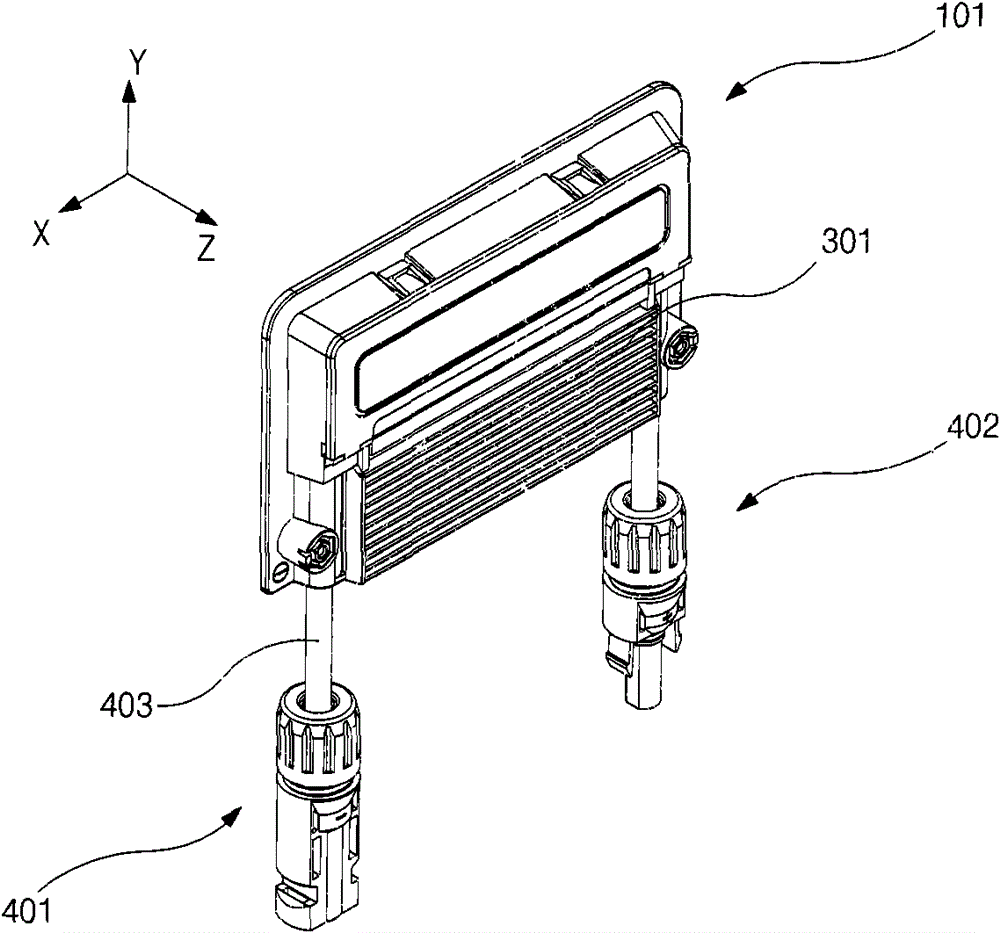

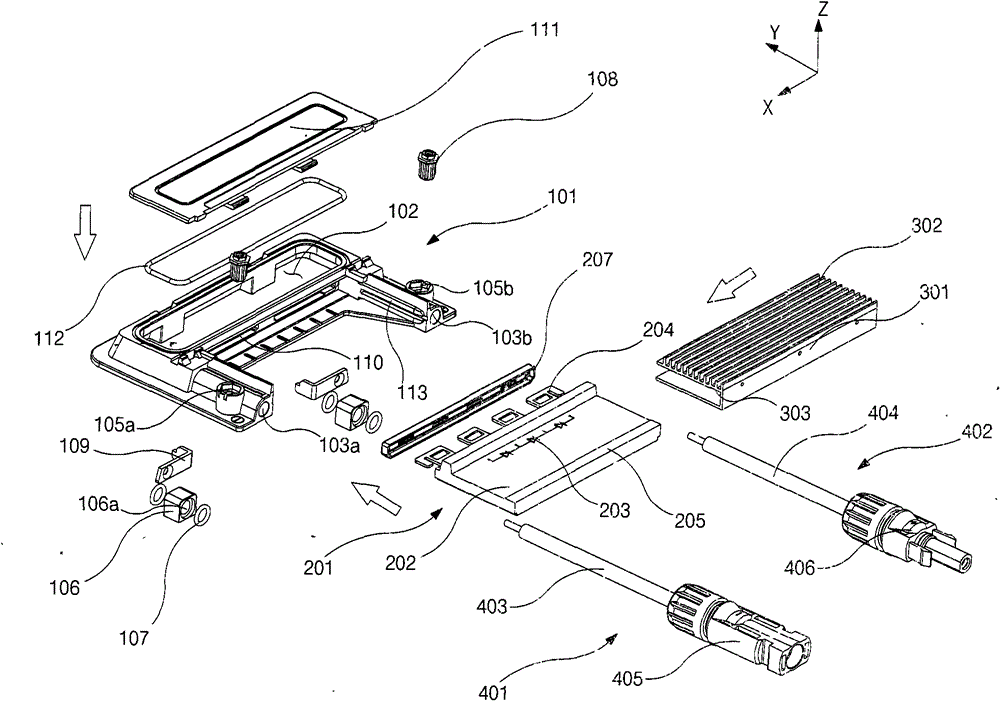

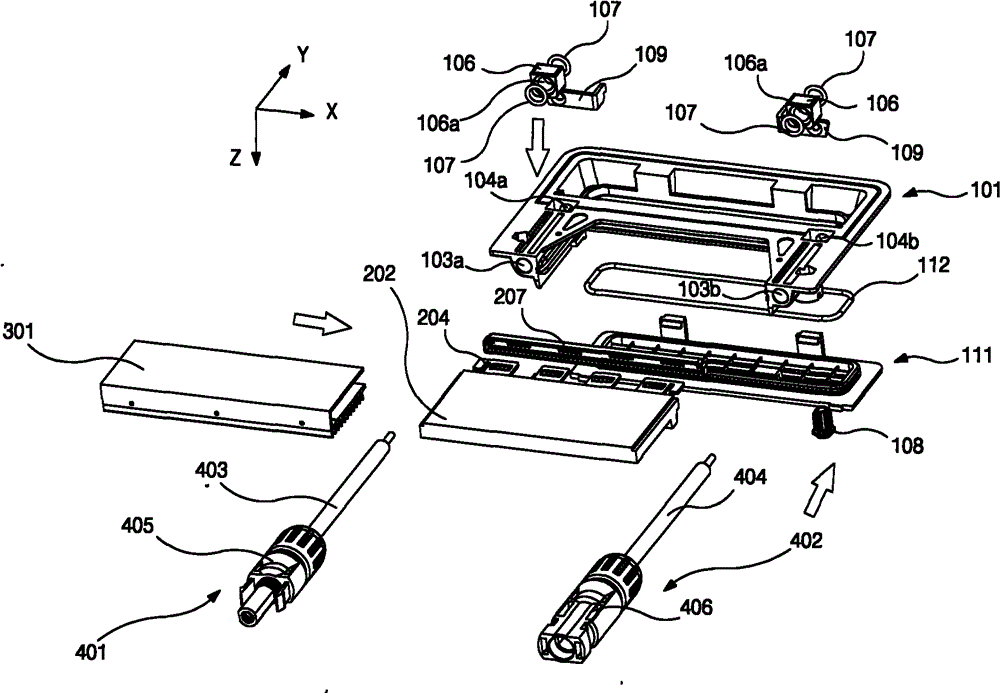

[0020] See attached figure 1 To attach image 3 The photovoltaic module junction box in this embodiment includes a junction box body 101, a working circuit module 201, a heat dissipation module 301, and connection modules 401, 402. The junction box body 101 can be molded from a plastic material at one time, and the heat dissipation module 301 can be made of a metal material.

[0021] as attached figure 2 with attached image 3 As shown, the junction box body 101 includes a side wall extending in the Z-axis direction and closed around the Z-axis. The bottom end of the side wall extends in the XY plane to form a flange, and the flange is attache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com