High-frequency driving device for electrodeless lamp

A technology for driving devices and electrodeless lamps, applied in lighting devices, light sources, electrical components, etc., can solve problems such as frequency drift of electrodeless lamp controllers, unstable signals of driving devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings.

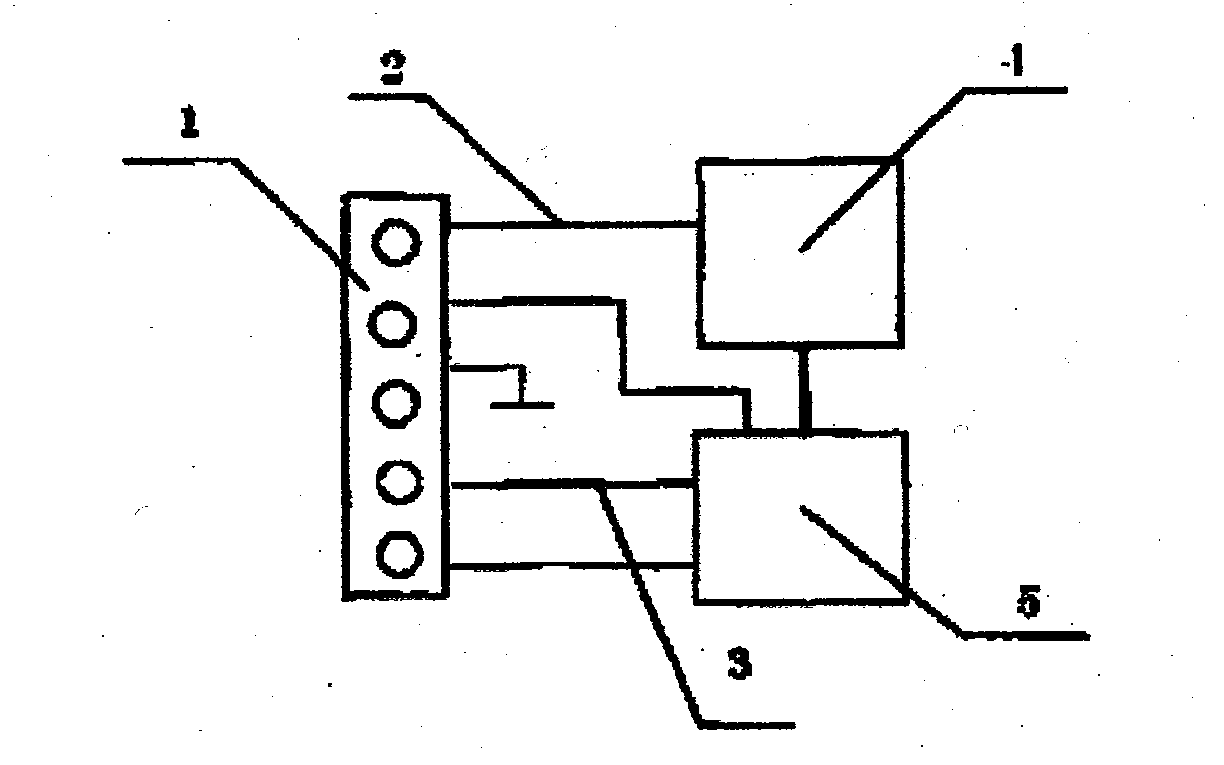

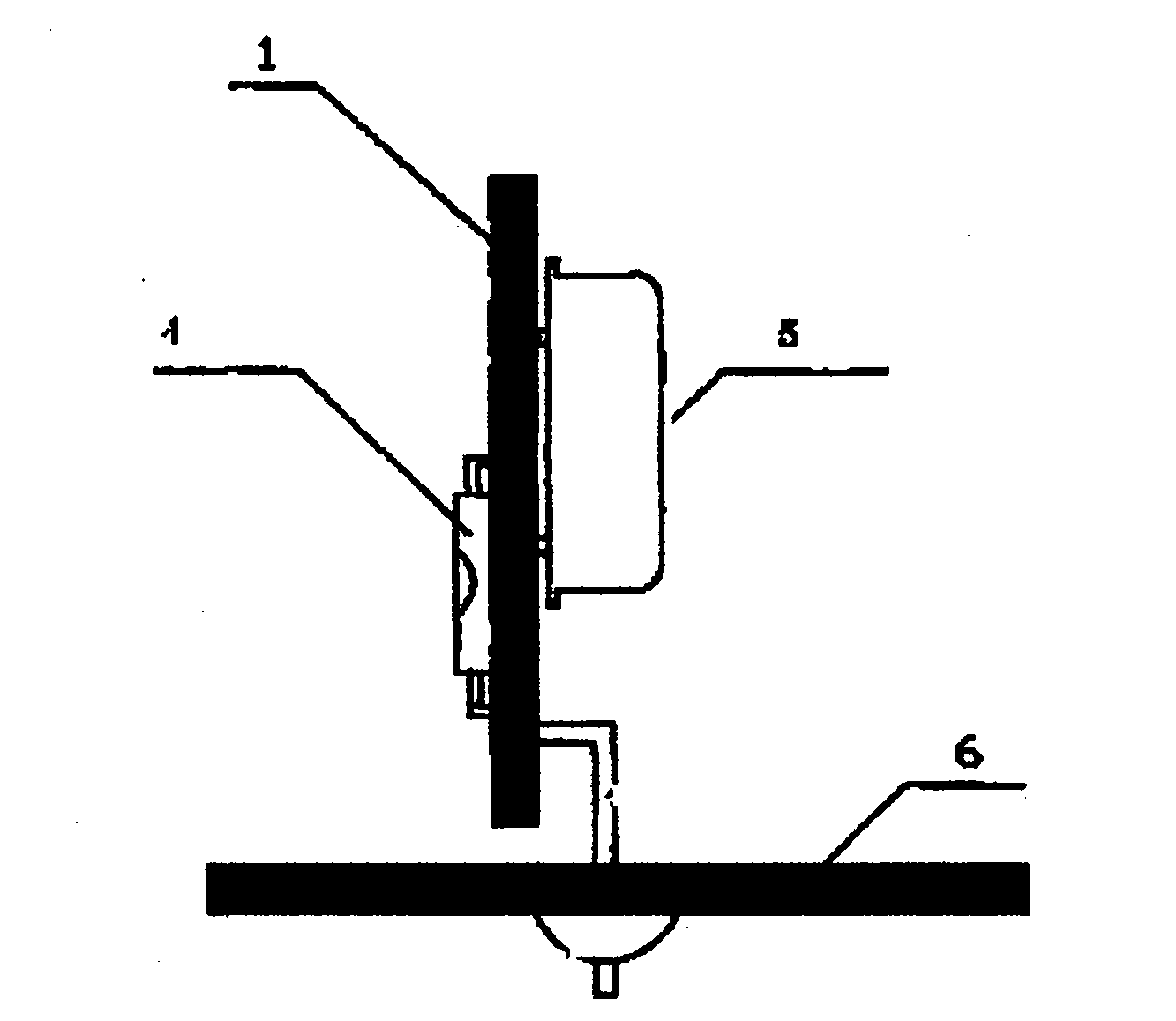

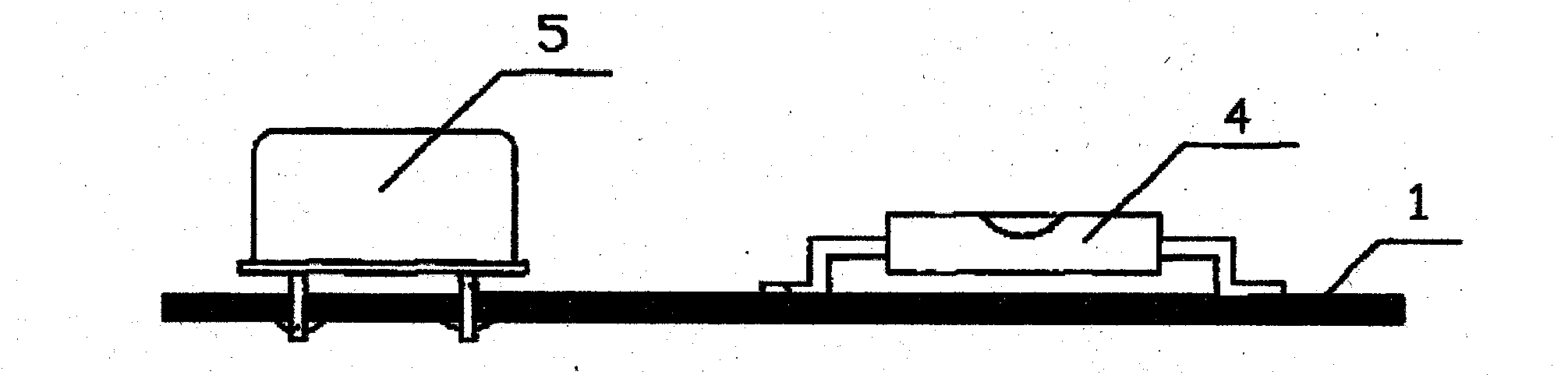

[0015] A high-frequency drive device for an electrodeless lamp, characterized in that it includes a PCB board 1, a first power supply 2, a second power supply 3, a crystal oscillator unit 4, and a drive chip 5, and the crystal oscillator unit 4 and the drive chip 5 Connect to the PCB board 1, the first power supply 2 supplies power to the crystal oscillator unit 4, the second power supply 3 supplies power to the driver chip 5, and is connected to the Power connection for the controller board 6.

[0016] The crystal oscillator unit 4 is a 2.65M main oscillation pulse generator, and the drive chip 5 is connected to the controller main board 6 through a pin.

[0017] When the nominal voltage reaches the crystal oscillator unit 4, the crystal oscillator circuit outputs a 2.65M standard pulse square wave to the drive chip 5, and the drive chip 5 outputs two sets of drive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com