Hydraulic brake master pump

A technology of hydraulic brake and brake fluid, applied in the direction of hydraulic brake transmission device, etc., can solve the problems of high production and assembly precision requirements, complicated installation, difficult product processing, etc., and achieves rapid and effective hydraulic transmission, simple overall structure, and convenience. The effect of forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

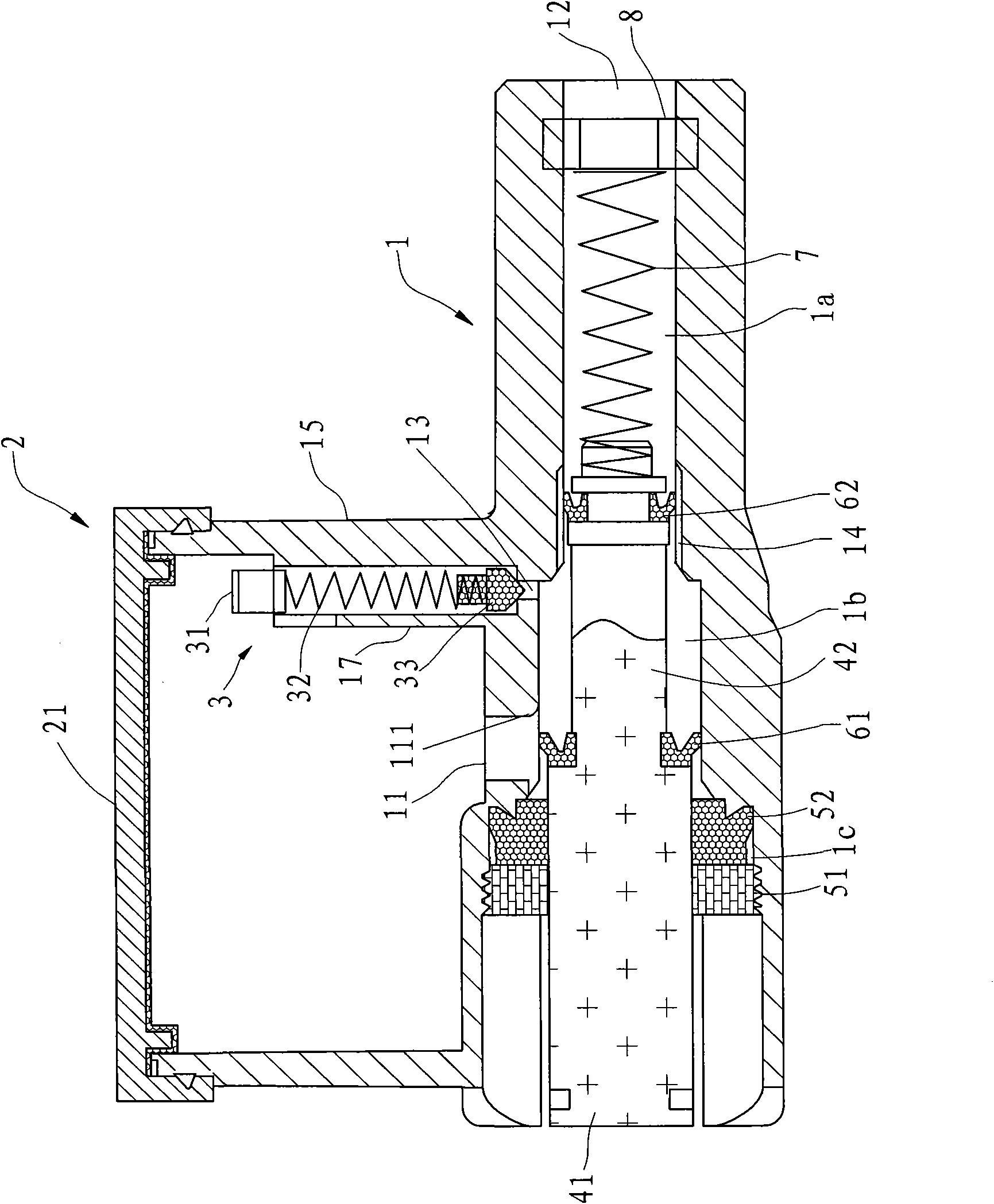

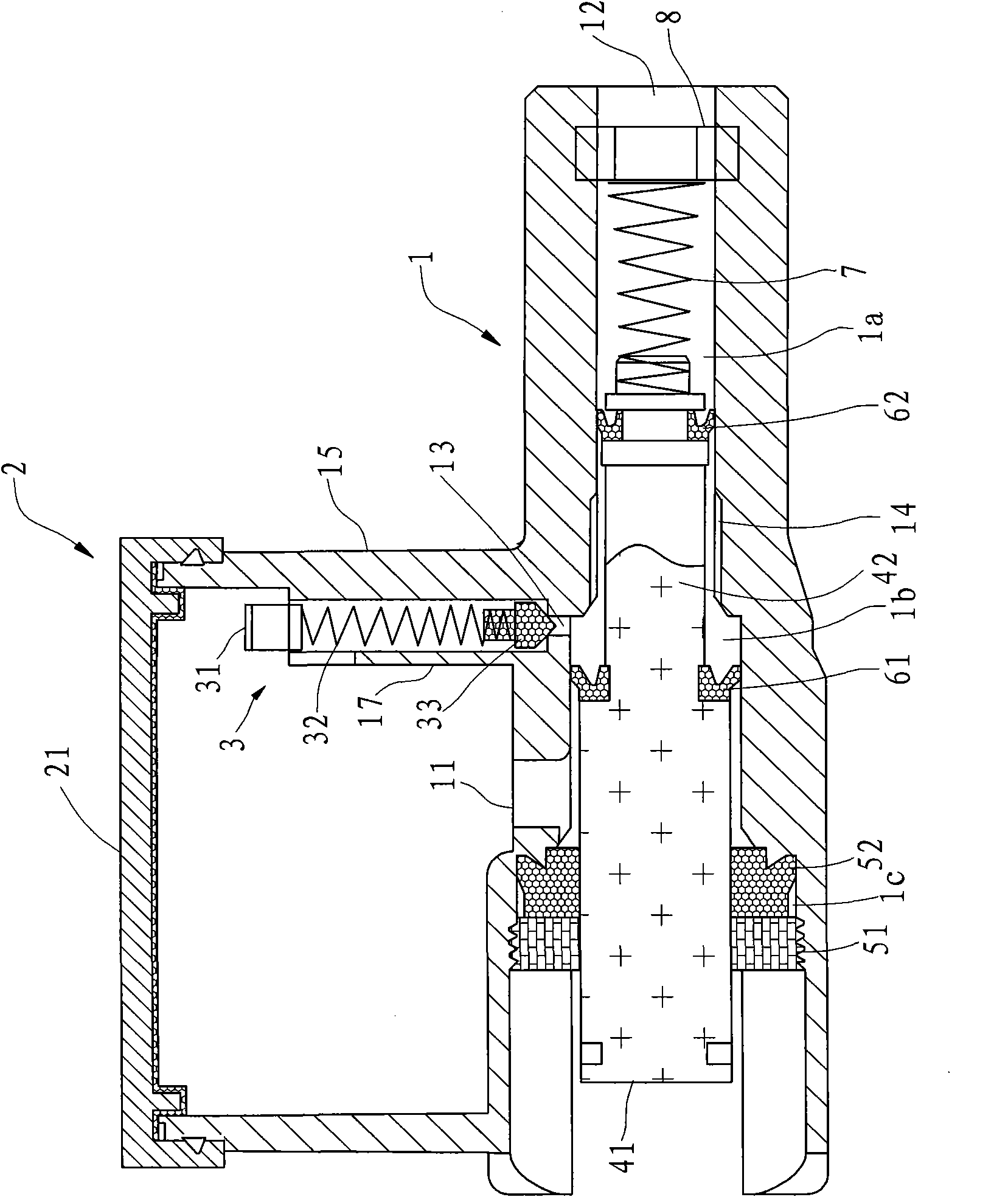

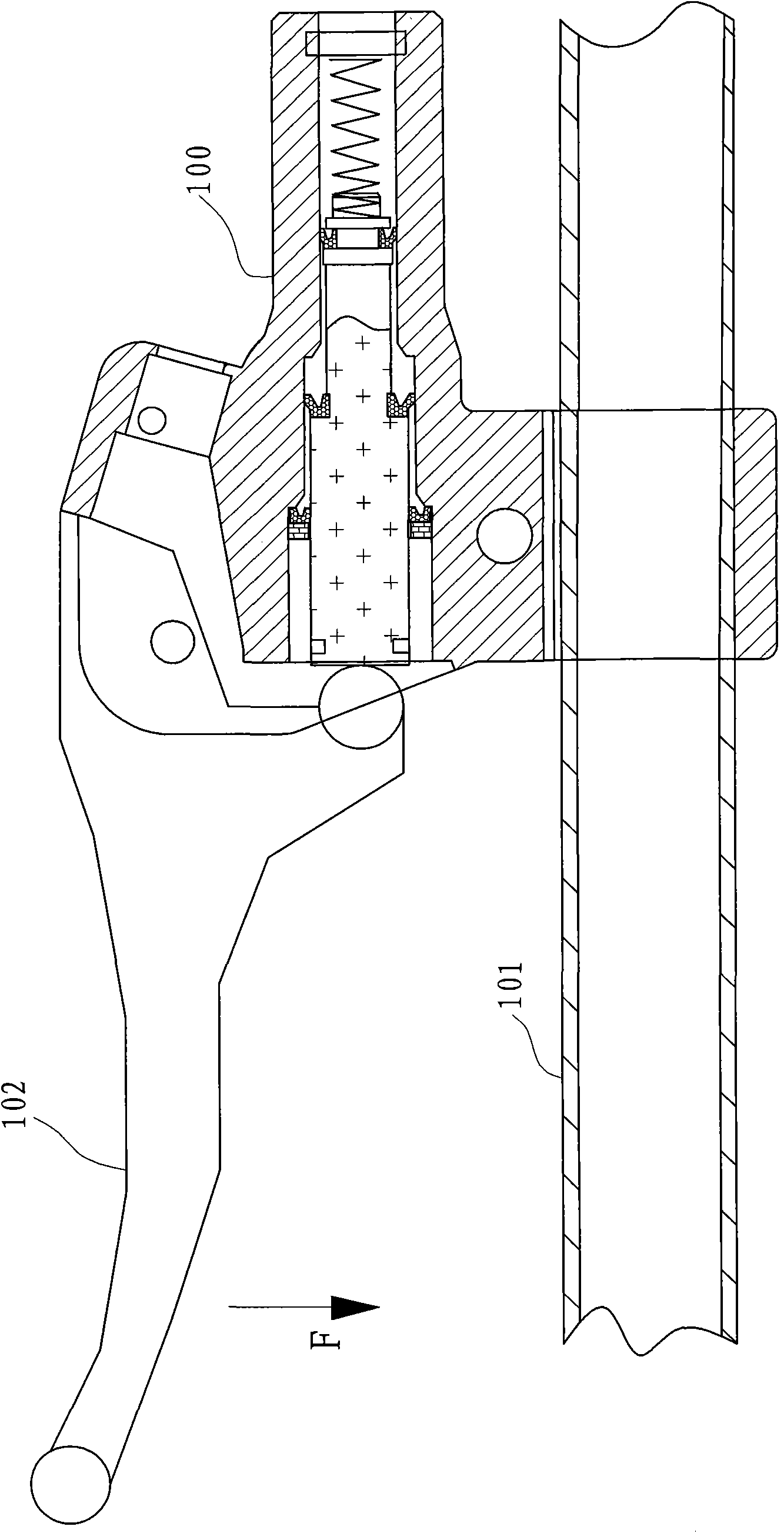

[0020] Such as figure 1 with figure 2 As shown, the hydraulic brake master cylinder in this embodiment includes a pump body 1, an oil cup 2 arranged on the pump body 1, a plunger arranged in the plunger chamber of the pump body 1 and capable of moving back and forth, a front sealing ring 62, Rear sealing ring 61 and the return spring 7 that can reset the plunger, one end of the return spring 7 is against the plunger, and the other end is arranged on the spring seat 8. The plunger includes a large plunger 41 and is located on the large plunger 41. The small plunger 42 at the front end, the large plunger 41 and the small plunger 42 are integrally formed parts, and are made of metal. The pump body 1 is formed with a raised surrounding wall 15 , the port cover of the surrounding wall 15 is provided with a cup cover 21 , and the surrounding wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com