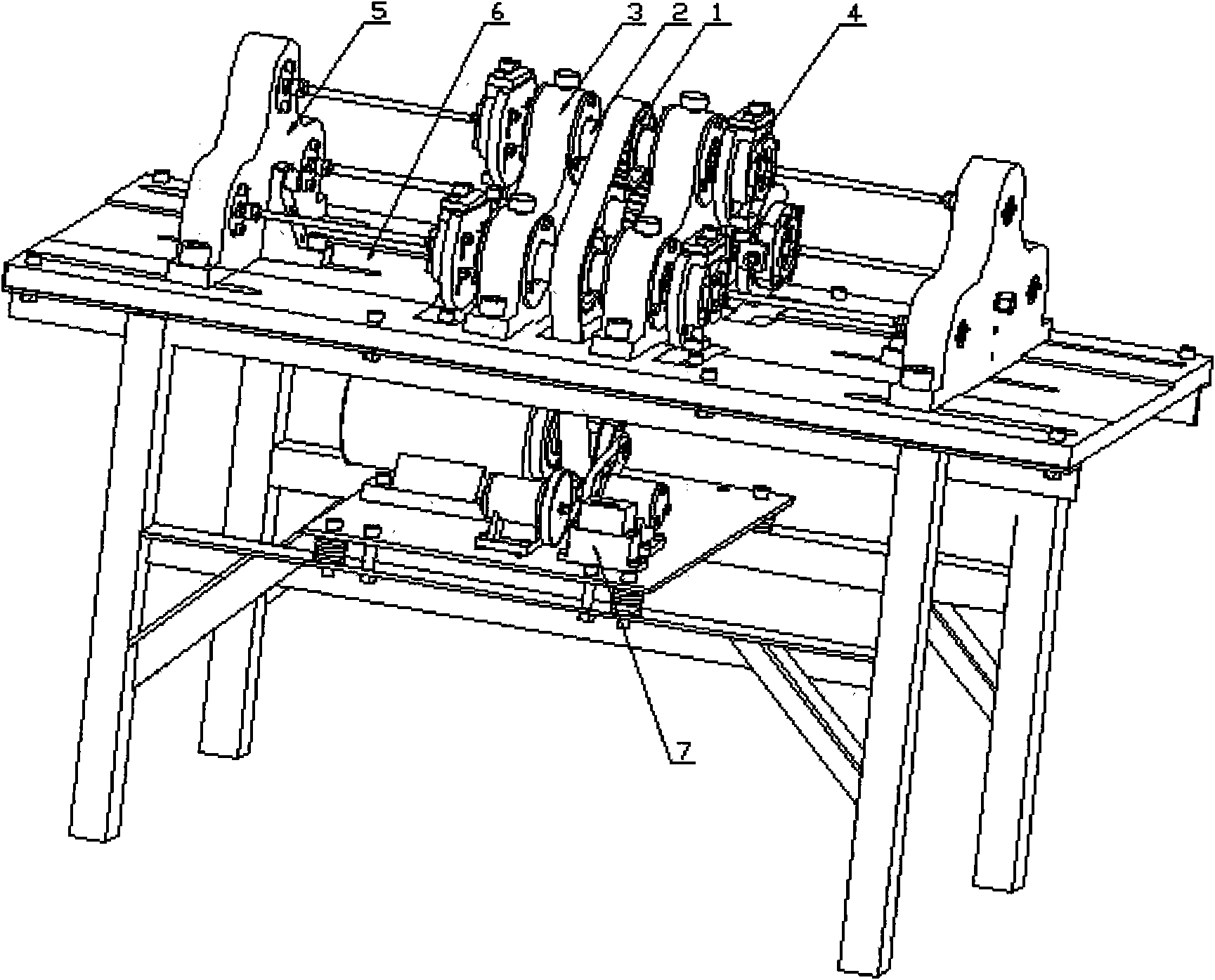

Rotary bending fatigue tester of aviation conduit assembly

A catheter assembly, bending fatigue technology, applied in the field of experimental testing equipment, can solve the problems of low test accuracy and efficiency, inconvenient maintenance, high price, etc., to achieve the effect of increasing the deflection adjustment range, reducing test costs, and improving the overall life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] There is a U-shaped groove running through the entire workbench on the workbench 6 of the aviation duct assembly rotary bending fatigue testing machine, and the riser in the main support vertical plate 3 and the tailstock shaft / tube installation and fixing mechanism 5 There is a U-shaped boss at the corresponding position on the bottom, which can play two roles. One is to effectively ensure the coaxiality of the corresponding shaft holes when the two main support vertical plates are installed, so as to ensure the centering of the main shaft installation. At the same time, it can also ensure the centering of the tube / shaft in the initial state of the later test; the second is that the distance between the main support vertical plate 3 and the tailstock shaft / tube installation and fixing mechanism 5 can be easily realized during the test, effectively adapting to different Length tube / shaft correlation experiments, increasing the versatility of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com