Energy-saving pumping unit

A pumping unit, energy-saving technology, applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of unreduced power consumption, large investment capital, high cost, etc., and achieve less material and less occupation The effect of land area and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

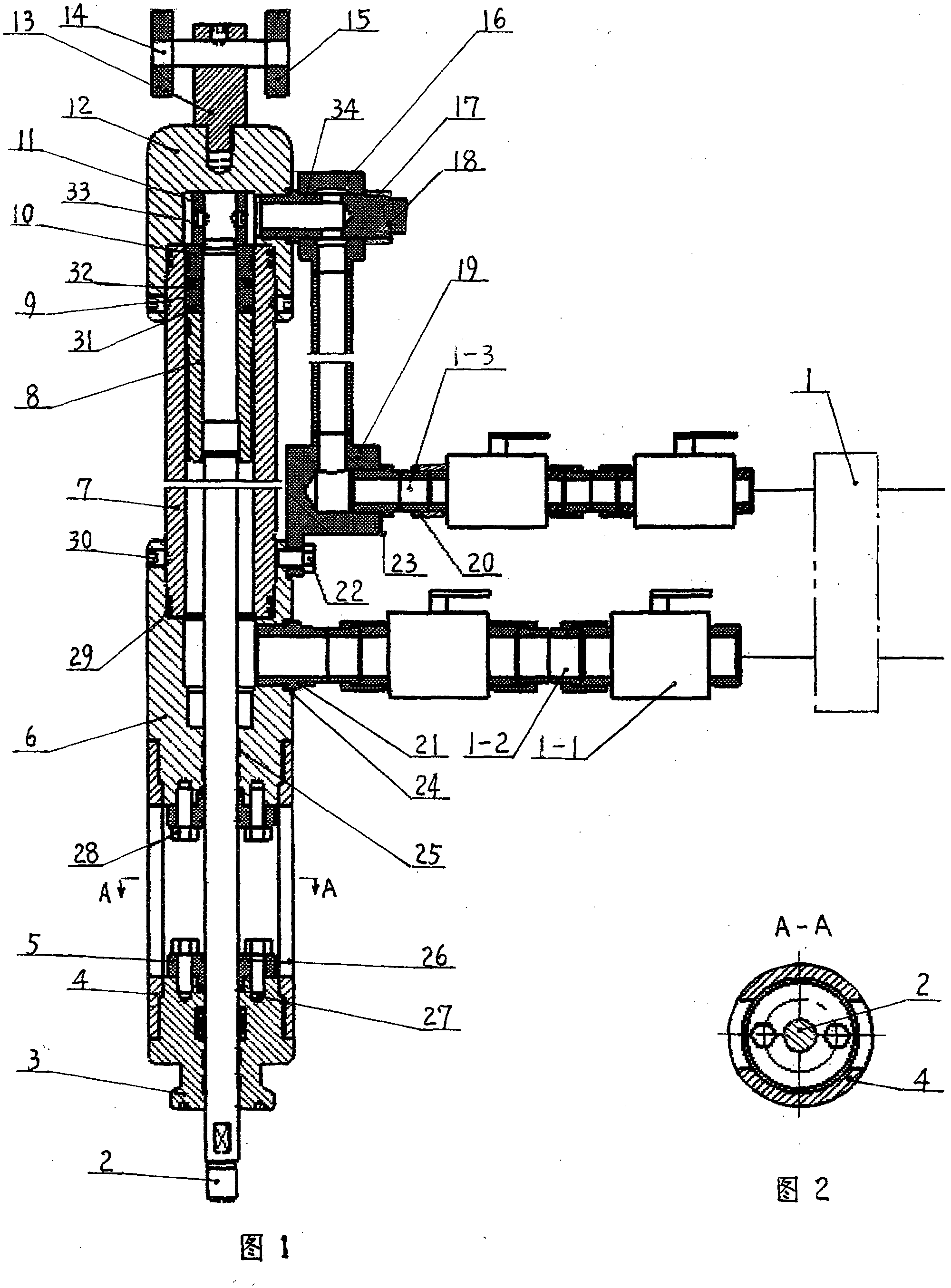

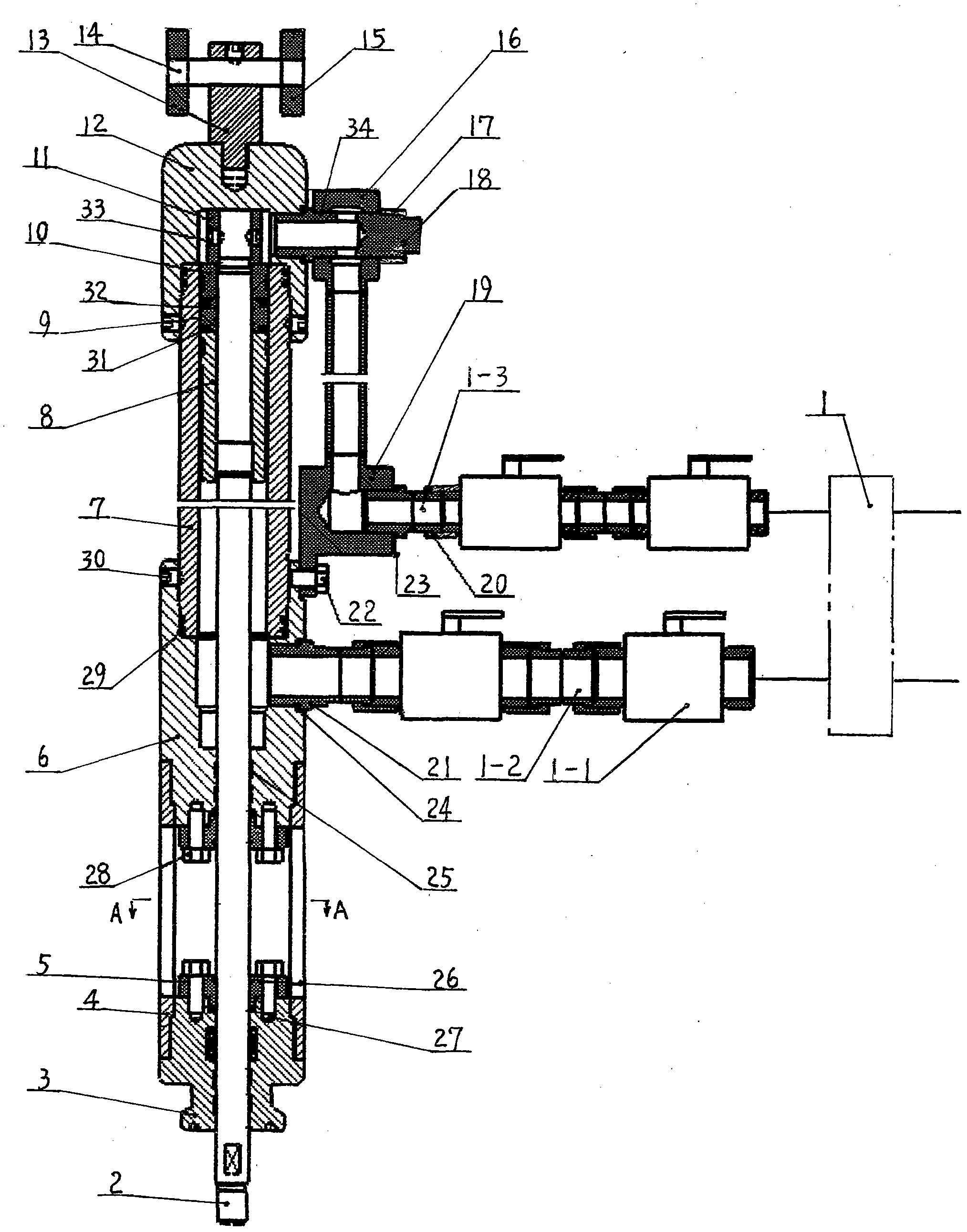

[0010] Examples, see attached figure 1 , 2 , the base packing box 3 of the energy-saving pumping unit passes through the piston rod 2 and is sealed and connected with the shaft seal 27, and the lower end of the connecting cylinder 4 is threadedly connected with the base packing box 3; The upper end and the lower end of the lower cylinder cap 6 are fixed by two hexagon head bolts 28, and there are dustproof rings 26 and shaft seals 27 in the packing gland 5; the upper end of the connecting cylinder 4 is threadedly connected with the lower end of the lower cylinder cap 6, and the lower cylinder cap Be guide band 25 in 6, lower cylinder cap 6 side holes are threadedly connected with welding joint 21, and combined gasket 24 is arranged in the connection. The pipeline 1-2 at the right end of the welding joint 21 is connected to the valve 1-1, the two valves 1-1 are connected with the pipeline 1-2, and the right end of the valve 1-1 is connected with the hydraulic system 1. The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com