Method for predicting fatigue life of lead-free solder joint in electronic packaging

A fatigue life prediction and electronic packaging technology, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of unreasonable data processing methods, insufficient data of thermophysical properties of lead-free materials, and affect the accuracy of life prediction and other issues to achieve the effect of shortening the development cycle, saving experiment costs and time, and improving accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A method for predicting the fatigue life of lead-free solder joints in electronic packages of the invention is used to predict the life of PBGA assembly lead-free solder joints.

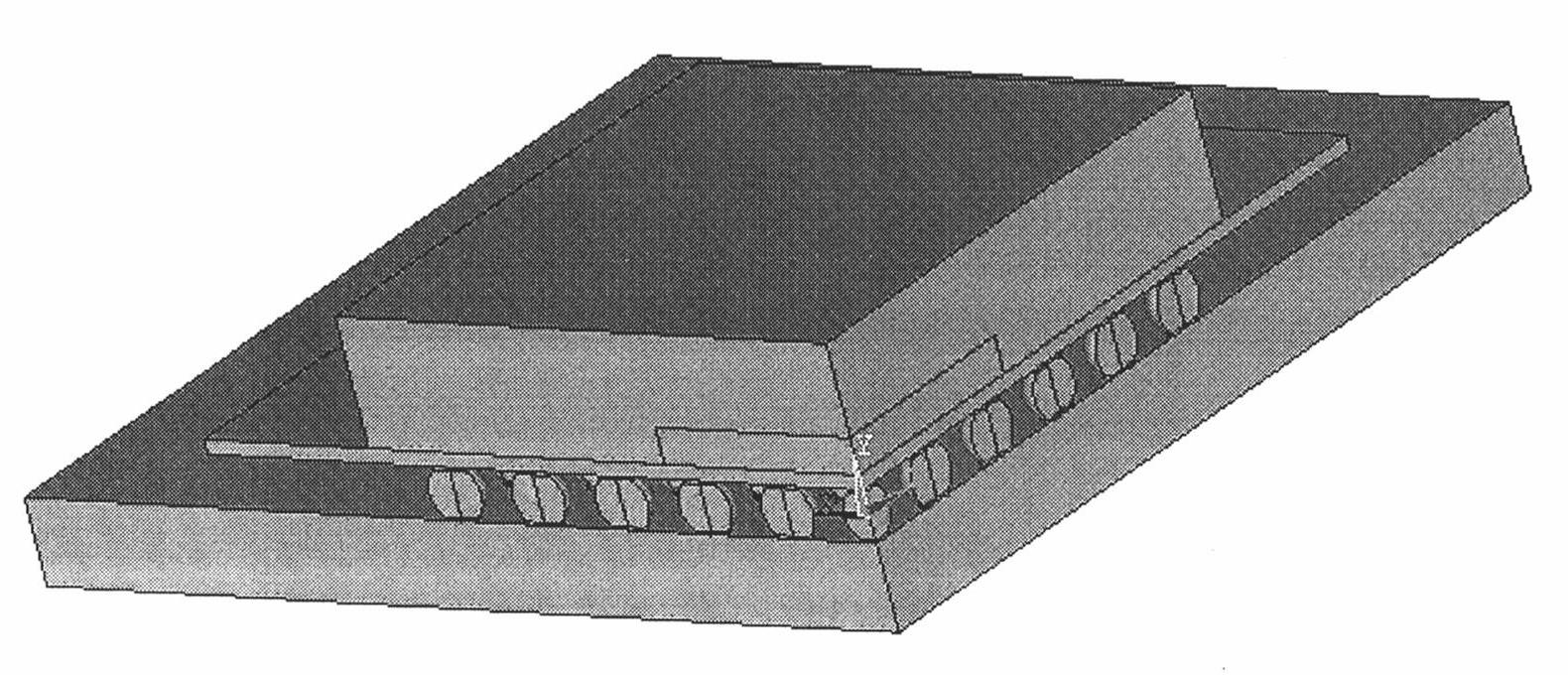

[0038] The specific research object is the solder joints of 11×11-PBGA packaged devices with solder balls arranged in a full array. figure 1 Shown is a 1 / 4 solid model of a PBGA packaged device.

[0039] In step (1), the performance parameters of the materials of each part of the electronic packaging device are obtained, and the constitutive model of the solder joint is determined;

[0040] The performance parameters of the materials of each part of the PBGA electronic packaging device studied in this example are obtained by consulting published literature, reports, etc., and the performance parameters of each part of the materials are shown in Table 1 and Table 2.

[0041]

[0042] Table 1 Material parameters of PBGA devices

[0043] temperature / ℃

-40

25

50

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com