Method for producing thermally tandem-rolled seamless steel pipes

A technology of seamless steel pipe and production method, applied in metal rolling and other directions, can solve the problems of high furnace charging temperature, difficult hot charging and hot delivery, design and actual production difficulties, etc., and achieve the effect of reducing burning loss and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

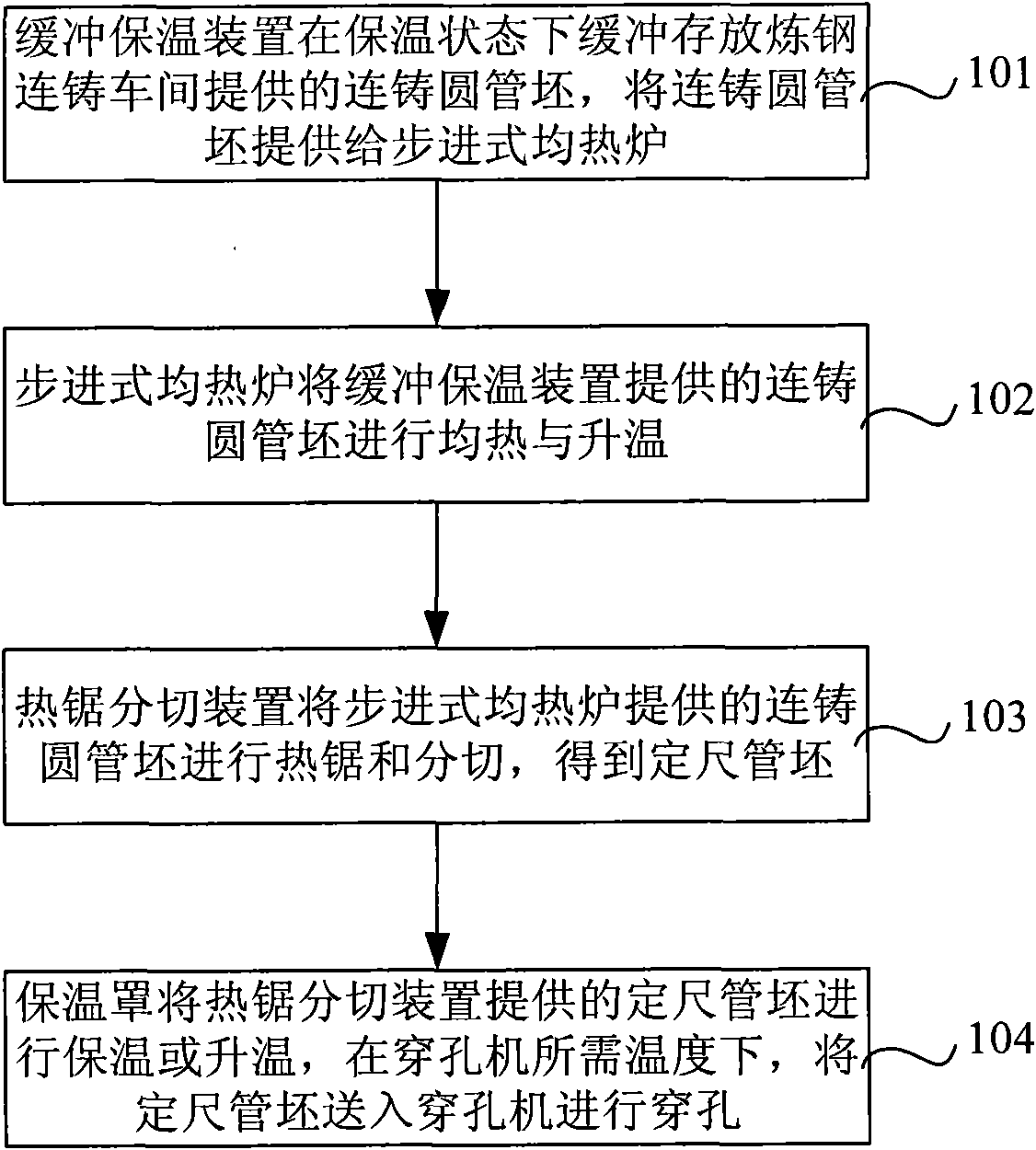

Method used

Image

Examples

Embodiment Construction

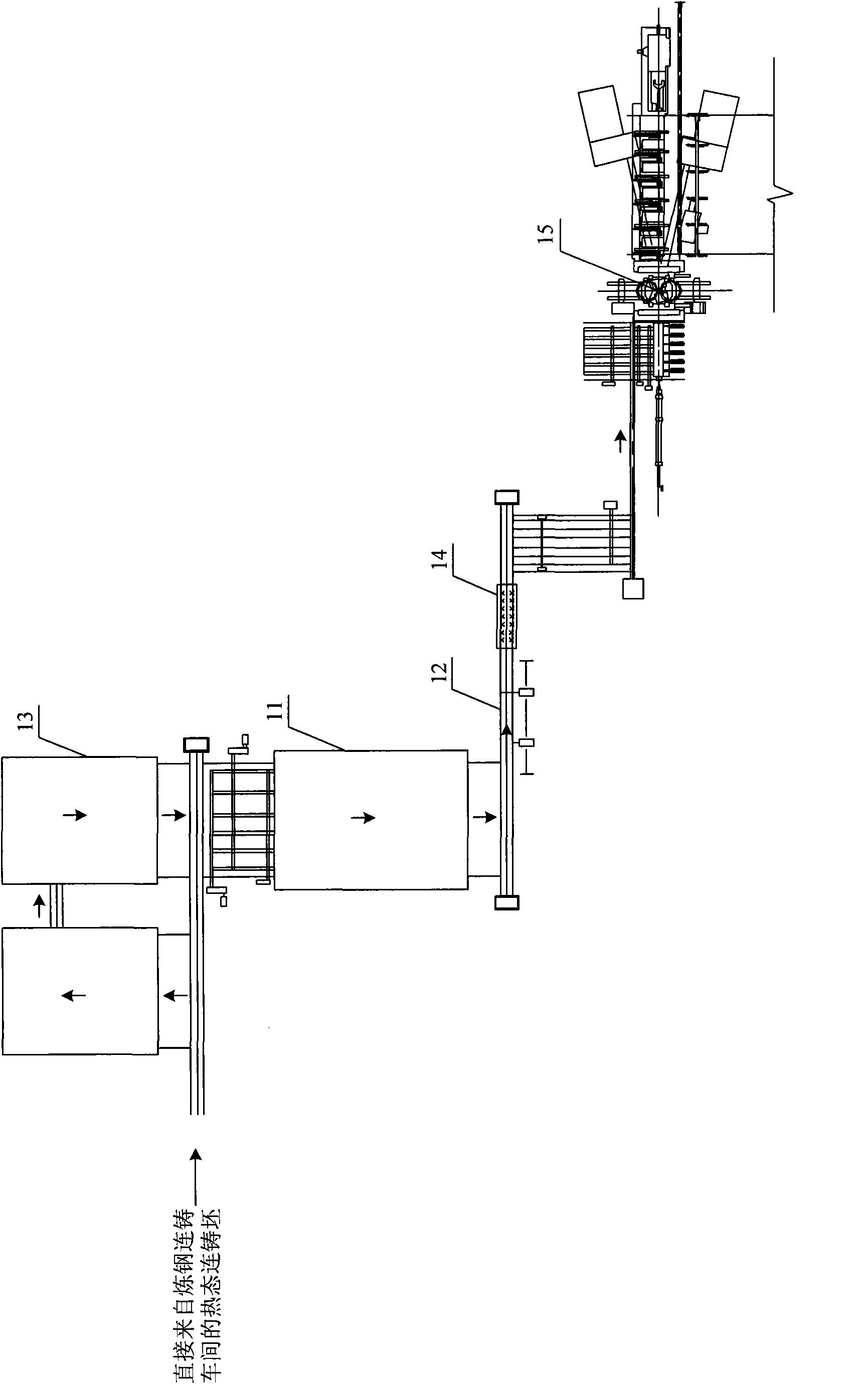

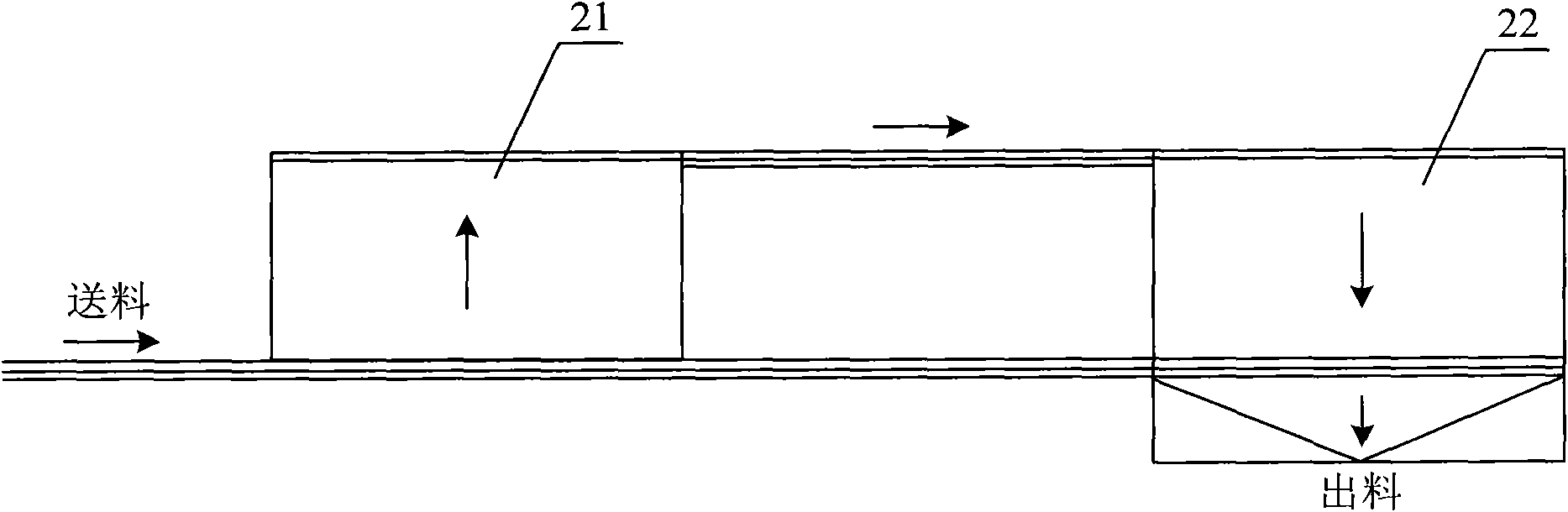

[0026] Since the annular furnace in the traditional seamless steel pipe production process cannot heat the tube blank with a length greater than or equal to 5m, the present invention uses a walking soaking furnace instead of the annular furnace to realize the functions of soaking and heating. Specifically, the walking-type soaking furnace raises the temperature of the continuous casting round billet provided by the steelmaking and continuous casting workshop at a temperature of 750-850°C and a length of 6-9m to 1150-1280°C; then, the hot saw cutting device will The continuous casting circular tube billet provided by the walking soaking furnace is hot sawed and cut to obtain a fixed-length tube billet with a length of 1.5-4.5m. The invention realizes the process of "hot charging and hot delivery", which can save more than 40% of energy and reduce burning loss of more than 1% compared with the traditional production process.

[0027] The technical solutions of the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com