Lithium battery with multilayer film heat dissipation structure, and soaking method thereof

A heat dissipation structure, lithium battery technology, applied in the direction of lithium batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of reducing the service life of the battery pack, failing to achieve the expected cooling, and increasing the temperature of the battery core, so as to reduce the overall Effects of temperature rise, waste avoidance, and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Performance comparison of a single cell, a single cell wrapped only with phase change material, and a single cell wrapped with phase change material and HDPE

[0034] Sample 1: single cell;

[0035] Sample 2: 6mm expanded graphite wrapped around a single cell;

[0036] Sample 3: A single cell is wrapped with 1.2mm HDPE and 4.8mm expanded graphite;

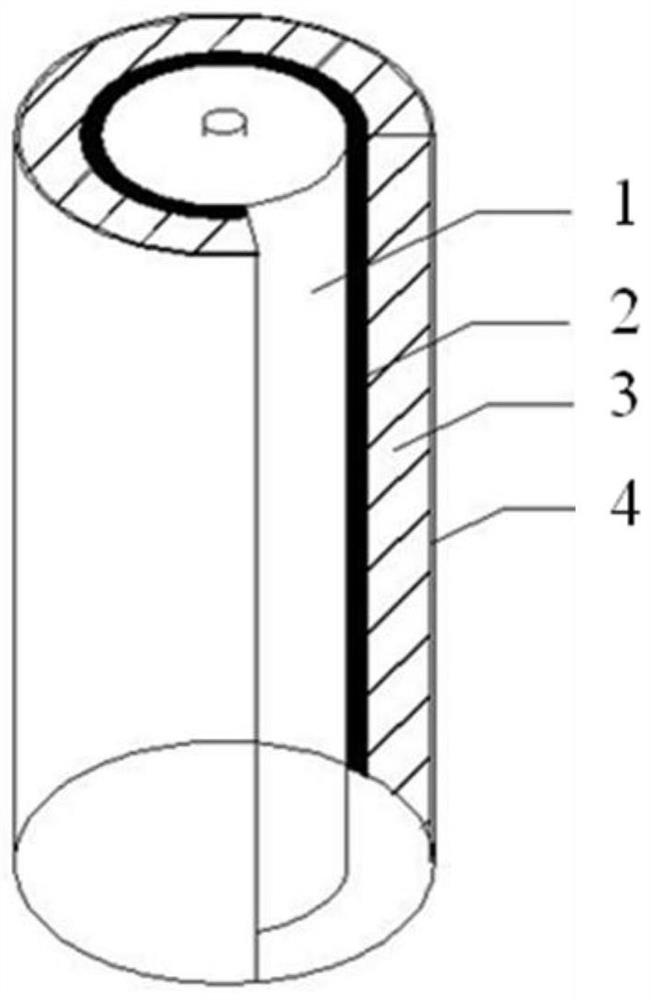

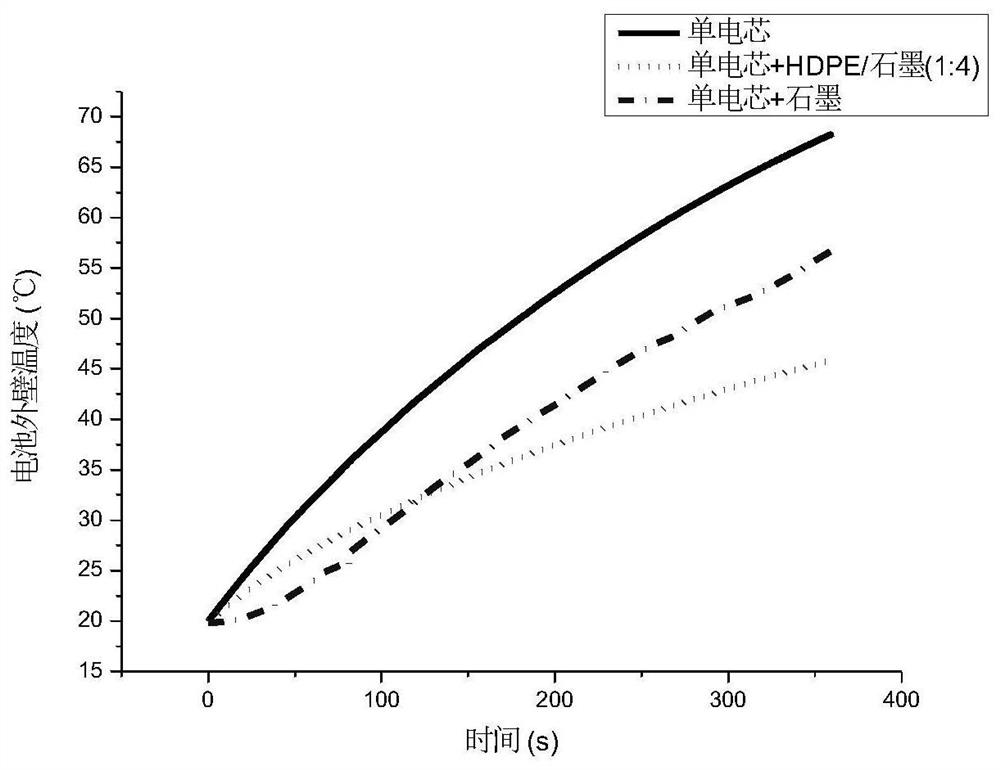

[0037] The single cells in samples 1 to 3 are the same, the single cell is sample 1, the single cell + graphite is sample 2, the single cell + HDPE / graphite (1:4) is sample 3, the structure of sample 3 is as follows figure 1 As shown: 1 is the battery core, 2 is the HDPE layer, 3 is the graphite layer, and 4 is the shell; research the temperature rise of samples 1 to 3 at a discharge rate of 10C, as shown in figure 2 As shown, the temperature of sample 1 is the fastest in the whole process, and the temperature increase of sample 2 is the smallest before 150s. The temperature of sample 2 and sample 3 is the same...

Embodiment 2

[0038] Example 2: Performance comparison of a single cell, a phase change material wrapped with different thickness ratios, and a single cell of HDPE

[0039] Sample 1: single cell;

[0040] Sample 2: A single cell is wrapped with 1.5mm HDPE and 4.5mm expanded graphite;

[0041] Sample 3: A single cell is wrapped with 1.2mm HDPE and 4.8mm expanded graphite;

[0042] Sample 4: A single cell is wrapped with 1mm HDPE and 5mm expanded graphite;

[0043]The single cells in samples 1 to 4 are the same, and the temperature rise of samples 1 to 4 at a discharge rate of 5C is studied. The temperature changes of each sample are shown in Table 1 below between 710s and 720s. From the results in the table, it can be known that each The temperature of the samples increases with the prolongation of the discharge time. The temperature of sample 1 has reached 38.7°C at 710s, while the temperature of sample 2 wrapped with HDPE and phase change material with a thickness ratio of 1:3 is only 30...

Embodiment 3

[0046] Embodiment 3: a kind of 20V 2Ah battery pack (the HDPE on both sides: graphite is 1:4, the HDPE in the middle: graphite is 1:3)

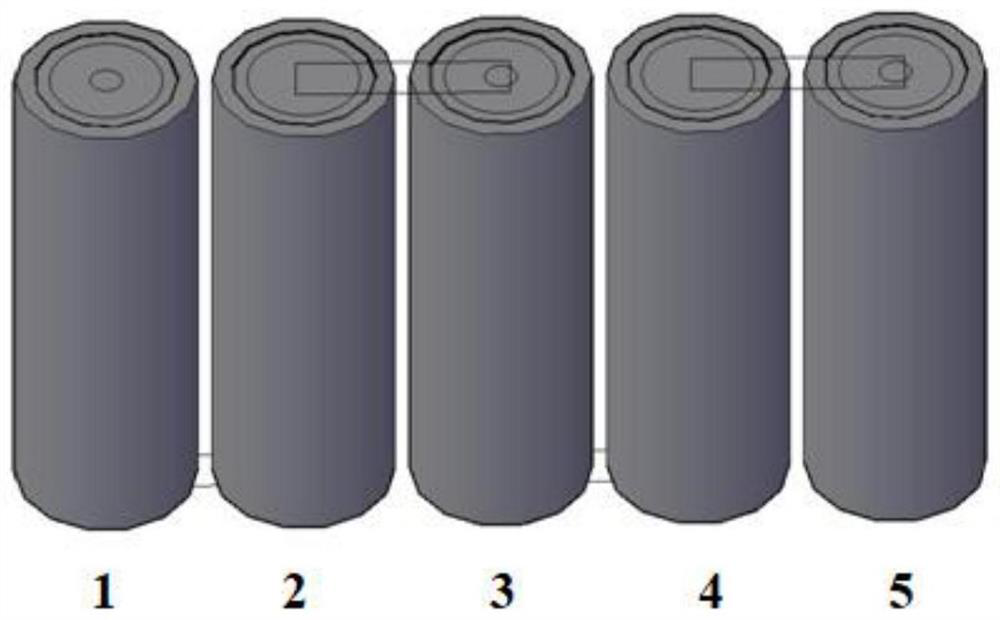

[0047] Connect five 18650-type lithium batteries in series to form a lithium battery pack in a 20V 2Ah battery pack. The nominal voltage of a single-cell lithium battery is 3.7V, and the actual full-charged single-cell lithium battery can reach 4V. batteries placed side by side, such as image 3 As shown: the batteries at positions 1 and 5 in the figure are batteries on both sides, and the batteries at positions 2-4 in the figure are batteries at the middle position. The preparation of the batteries at both sides and the middle position is as follows:

[0048] Batteries on both sides: Wrap 1.2mm HDPE and 4.8mm expanded graphite on the outside of the single cell, and then wrap it with a heat-conducting shell to obtain batteries placed on both sides.

[0049] The battery in the middle part: wrap 1.5mm HDPE and 4.5mm expanded graphite on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com