Method for producing maotai-flavor white spirit

A sauce-flavor liquor and sauce-flavor technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of increasing the quality of liquor at various levels in the cellar, not much, etc., and achieve the effect of improving the quality of base liquor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] (1), under the sand:

[0079] After the raw materials are crushed, use 90°C hot water to pile up the moist grains, and turn them rough while steaming to make them absorb water evenly and avoid the loss of slurry. After 2 hours of stacking, do the second steaming. After 10 hours of stacking, you can steam the grains in a retort , the total water production accounts for 42% to 48% of the grain;

[0080] Put the raw materials that have been accumulated and moistened into a retort and cook for 2.5 hours, then take out the retort, and pour water with a temperature of about 85°C at a temperature of about 12% of the amount of raw materials after taking out the retort;

[0081] When the uncooked sand after water measurement cools down to about 32°C, add Daqu powder, the amount of added koji is about 10% of the feeding amount, after adding koji, accumulate and ferment for 5 days, and when the top temperature rises to 55°C, accumulate and ferment Mix the uncooked sand wine grain...

Embodiment 2

[0101] (1), under the sand:

[0102] After the raw materials are crushed, use 90°C hot water to pile up the moist grains, and turn them rough while steaming to make them absorb water evenly and avoid the loss of slurry. After 2 hours of stacking, do the second steaming. After 10 hours of stacking, you can steam the grains in a retort , the total water production accounts for 42% to 48% of the grain;

[0103] Put the raw materials that have been accumulated and moistened into a retort and cook for 2.5 hours, then take out the retort, and pour water with a temperature of about 85°C at a temperature of about 12% of the amount of raw materials after taking out the retort;

[0104]When the uncooked sand after water measurement cools down to about 32°C, add Daqu powder, the amount of added koji is about 10% of the feeding amount, after adding koji, accumulate and ferment for 5 days, and when the top temperature rises to 55°C, accumulate and ferment Mix the uncooked sand wine grains...

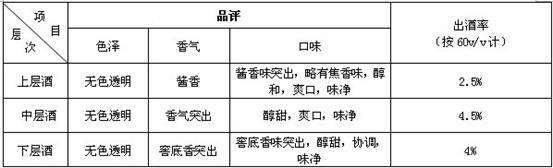

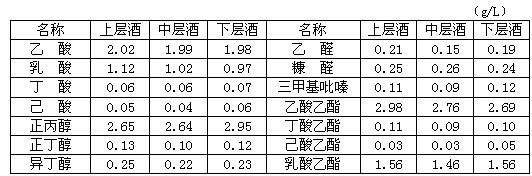

Embodiment 3

[0124] A normal production cellar with 12 retorts was selected for testing. The walls of the cellar pool are made of stone strips, and the bottom mud of the pit is artificial pit mud.

[0125] (1), under the sand:

[0126] After the raw materials are crushed, use 90°C hot water to pile up the moist grains, and turn them rough while steaming to make them absorb water evenly and avoid the loss of slurry. After 2 hours of stacking, do the second steaming. After 10 hours of stacking, you can steam the grains in a retort , the total water production accounts for 42% to 48% of the grain;

[0127] Put the raw materials that have been accumulated and moistened into a retort and cook for 2.5 hours, then take out the retort, and pour water with a temperature of about 85°C at a temperature of about 12% of the amount of raw materials after taking out the retort;

[0128] When the uncooked sand after water measurement cools down to about 32°C, add Daqu powder, the amount of added koji is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com