Agrocybe cylindracea and shiitake mushroom stem submicron powder fermented seasoning and production method thereof

A technology of shiitake mushroom stalk and tea tree mushroom, which is applied in the direction of food science, etc., can solve the problems of high crude fiber content, difficulty in digestion and absorption, waste of shiitake mushroom stalk, etc., and achieve the effect of simple production process, outstanding sauce flavor, and improved dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

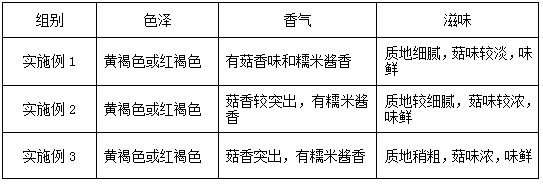

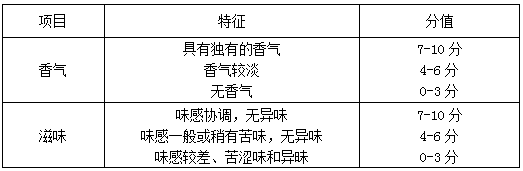

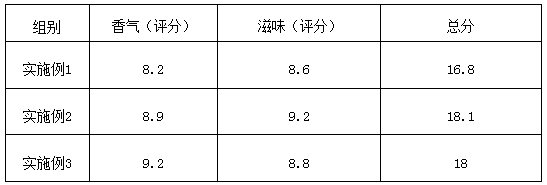

Examples

Embodiment 1

[0021] The tea tree mushroom and shiitake stalk superfine powder fermented seasoning is composed of the following raw materials in parts by weight: 2 parts of tea tree mushroom, 2 parts of shiitake stalk, 8 parts of glutinous rice, 1 part of salt, 15 parts of water, and 0.02 part of aspergillus oryzae koji essence.

[0022] The number of Aspergillus oryzae spores in the Aspergillus oryzae koji essence is more than or equal to 10 9 pcs / g.

[0023] A kind of fermented seasoning of tea tree mushroom shiitake stalk superfine powder according to the present invention, its production method is:

[0024] (1) Select non-deteriorated tea tree mushrooms, remove impurities, wash them, and then process them at 100°C for 30 seconds to blanch and sterilize them, then dry them until the water content is ≤5%, and primary crush them through an 80-mesh sieve to obtain tea tree mushroom powder. Then pulverized by an ultrafine pulverizer to obtain superfine powder of tea tree mushroom, with a pa...

Embodiment 2

[0029] A tea tree mushroom and shiitake stalk superfine powder fermented seasoning is composed of the following raw materials in parts by weight: 4 parts of tea tree mushroom, 4 parts of shiitake stalk, 8 parts of glutinous rice, 3 parts of salt, 18 parts of water, and 0.08 part of aspergillus oryzae koji essence;

[0030] The number of Aspergillus oryzae spores in the Aspergillus oryzae koji essence is more than or equal to 10 9 pcs / g.

[0031] A kind of fermented seasoning of tea tree mushroom shiitake stalk superfine powder according to the present invention, its production method is:

[0032] (1) Select non-deteriorated tea tree mushrooms, remove impurities, wash them, and then process them at 100°C for 45 seconds for blanching and sterilization, then dry them until the water content is ≤5%, and primary crush them through an 80-mesh sieve to obtain tea tree mushroom powder. Then pulverized by an ultrafine pulverizer to obtain superfine powder of tea tree mushroom, with a ...

Embodiment 3

[0037] A tea tree mushroom and shiitake stalk superfine powder fermented seasoning is composed of the following raw materials in parts by weight: 8 parts of tea tree mushroom, 8 parts of shiitake stalk, 8 parts of glutinous rice, 4 parts of salt, 25 parts of water, and 0.15 part of aspergillus oryzae koji essence;

[0038] The number of Aspergillus oryzae spores in the Aspergillus oryzae koji essence is more than or equal to 10 9 pcs / g.

[0039] A kind of fermented seasoning of tea tree mushroom shiitake stalk superfine powder according to the present invention, its production method is:

[0040] (1) Select non-deteriorated tea tree mushrooms, remove impurities, wash them, and then process them at 100°C for 60 seconds to blanch and sterilize them, then dry them until the water content is ≤5%, and primary crush them through an 80-mesh sieve to get tea tree mushroom powder. Then pulverized by an ultrafine pulverizer to obtain superfine powder of tea tree mushroom, with a partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com