Flash low molecular removal device with cooling pipes

A cooling tube and molecular device technology, applied in flash evaporation and other directions, can solve the problems of unsatisfactory vacuum degree of de-decreasing molecular device, difficult extrusion of products, yellowing of rubber materials, etc., to shorten residence time, reduce temperature, prevent yellowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

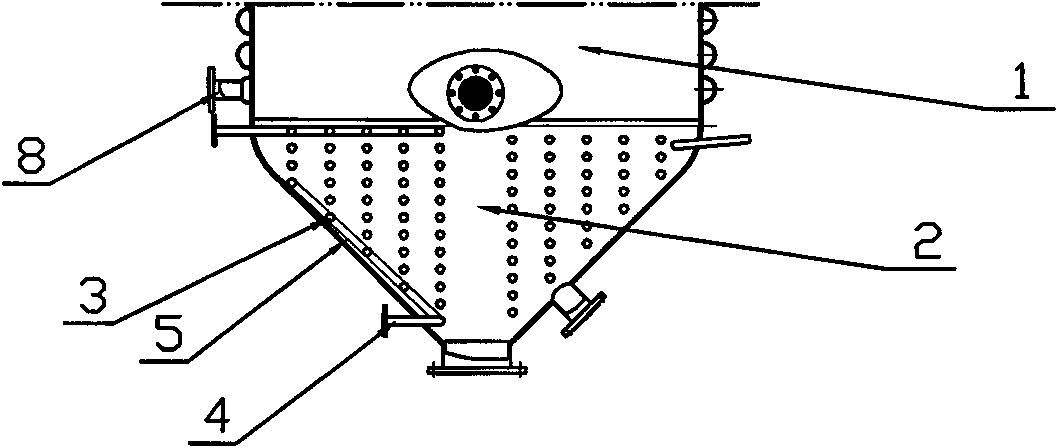

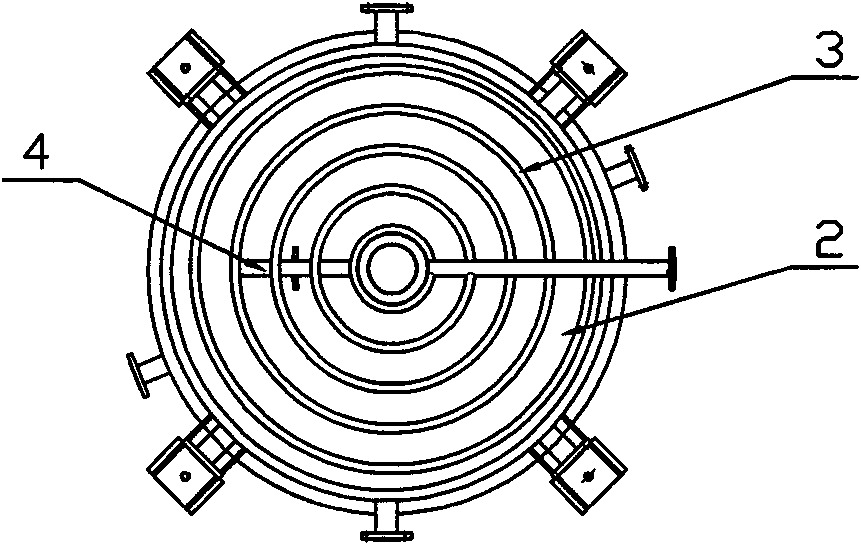

[0013] refer to figure 1 , figure 2 , a flash type delowering device with a cooling tube, a coiled cooling tube 3 in the conical bottom 2 of the tank 1 of the delowing molecular device, and a cooling liquid inlet 4 on the coiled cooling tube 3 The cooling liquid inlet 4 is respectively connected to the coiled cooling pipes 3 of each layer through a section of straight pipe 5 , and a cooling liquid outlet 8 is provided above the coiled cooling pipes 3 .

[0014] The coiled cooling pipes 3 have 2-8 layers, and each layer of the coiled cooling pipes 3 has a liquid inlet and communicates with the cooling liquid inlet 4 through a straight pipe 5 .

Embodiment 2

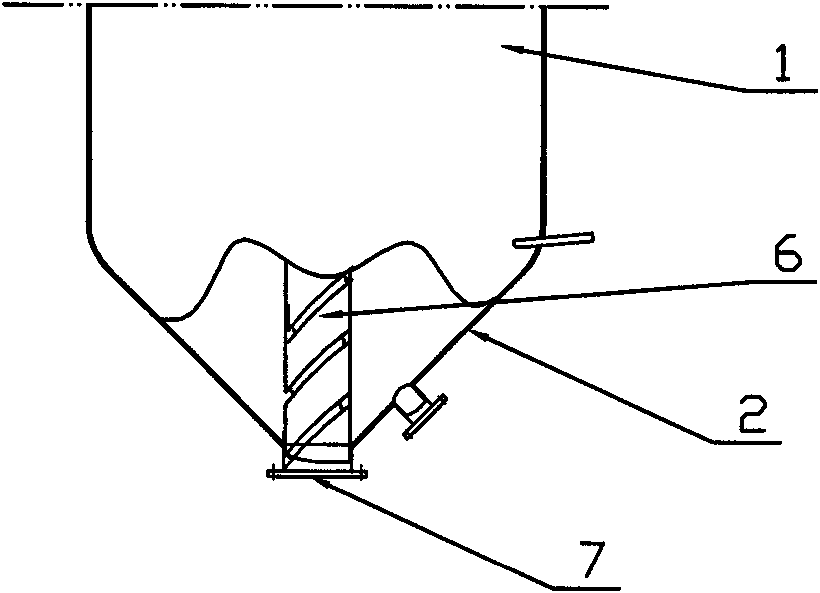

[0016] The difference between this embodiment and the first embodiment lies in that: there is an internal detection screw extruder 6 inside the discharge port 7 on the conical bottom 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com