Method for preparing fertilizer grade monoammonium phosphate from sulfurous gases by ammonia-process desulfurization

A technology for preparing fertilizers and gaseous ammonia, applied in the direction of separation methods, ammonium orthophosphate fertilizers, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

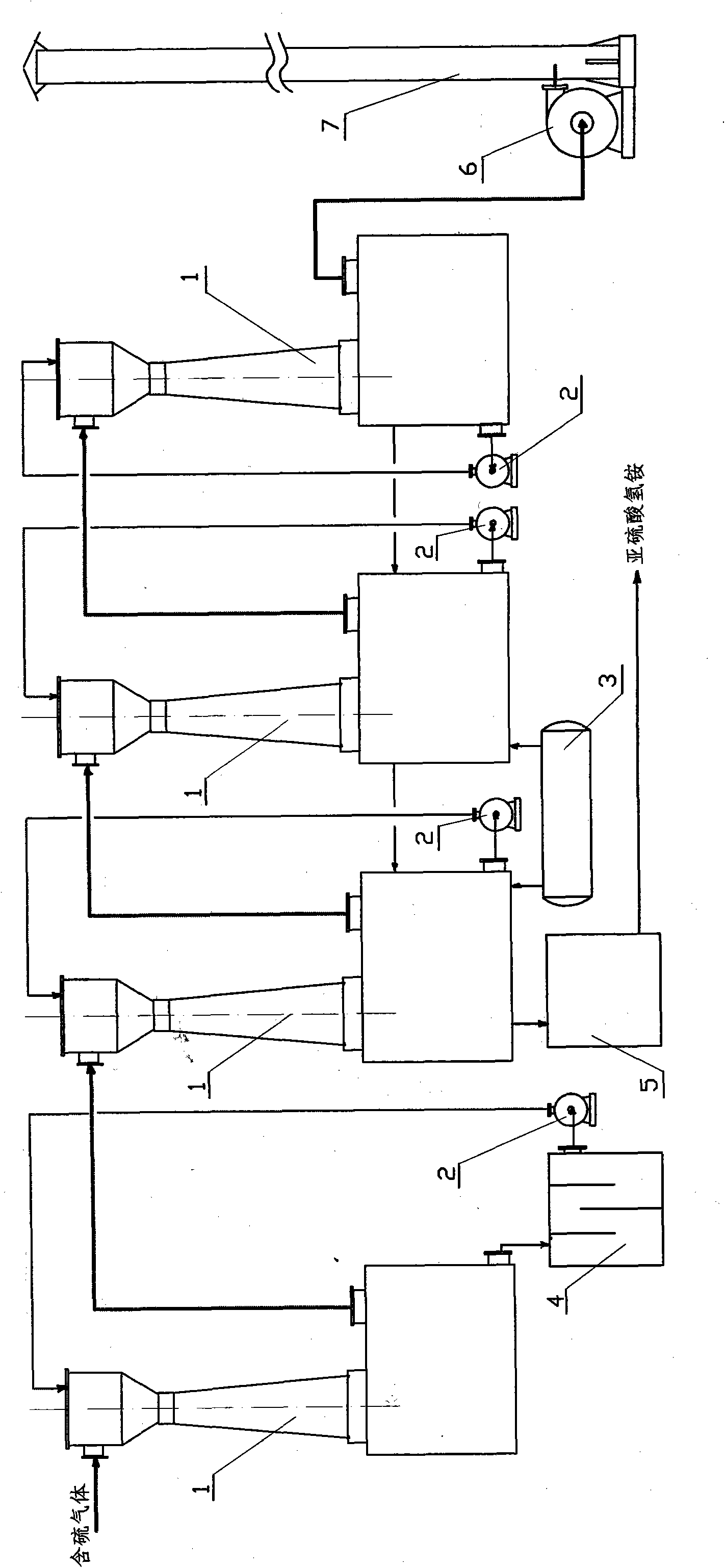

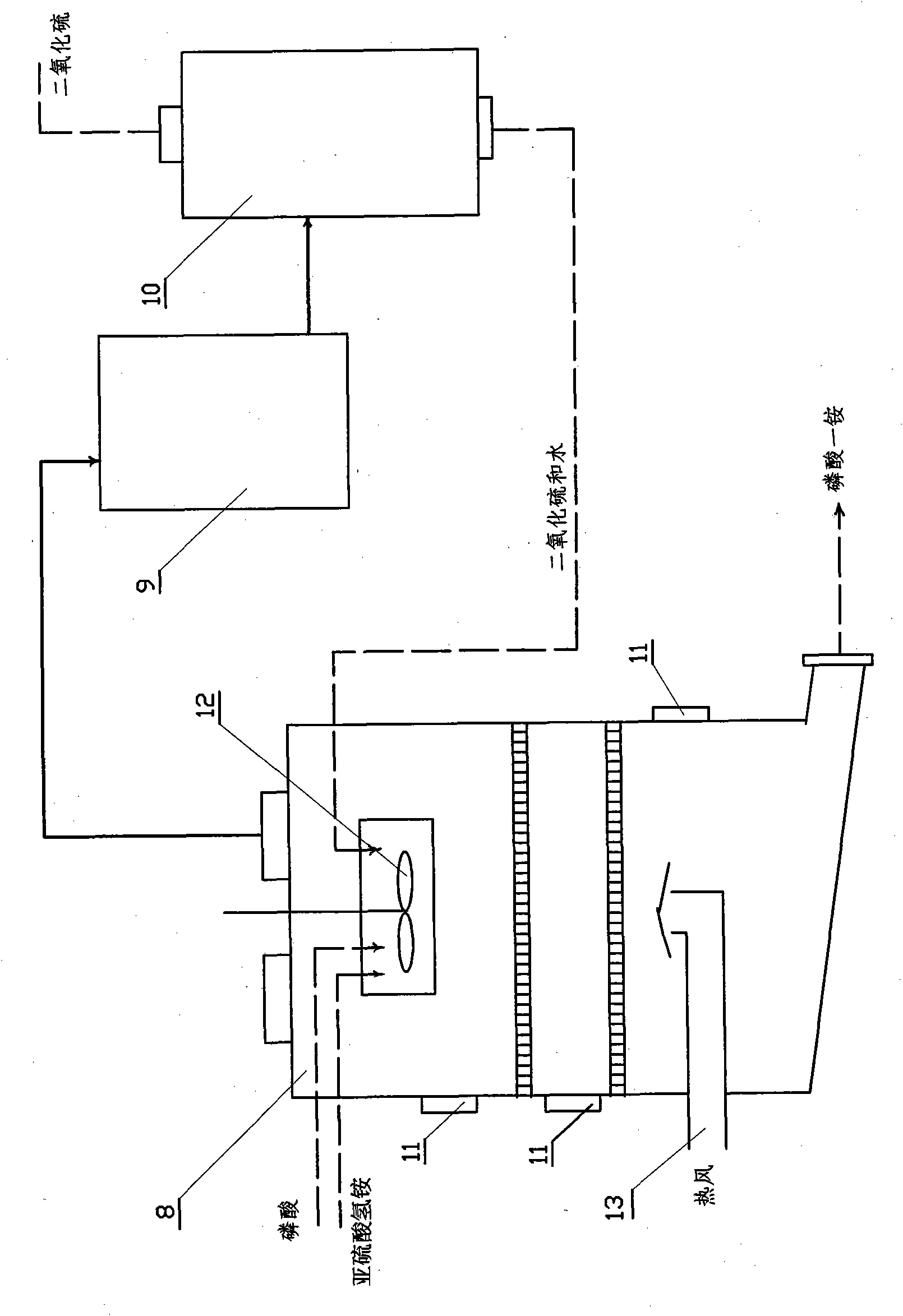

Method used

Image

Examples

Embodiment

[0032] One set of 6.5×10 in a thermal power plant 4 The kW boiler consumes 200kt of coal per year, and the average sulfur mass fraction of the coal is 3.5%. If the sulfur is recovered by the method of the present invention, 20kt of sulfuric acid can be produced every year based on a sulfur utilization rate of 93.3%.

[0033] The gas output of the boiler is 2.5×10 5 m 3 / h, temperature 180°C, flue gas dust content 50g / m 3 , SO 2 The mass fraction is 10~12g / m 3 .

[0034] Coal-fired flue gas SO 2 The emission standard is 700~1200mg / m 3 . Adopt the inventive method, with ammonia desulfurization, in order to guarantee the utilization rate of ammonia, SO 2 The emission must be controlled at 100mg / m 3 Below, that is to say, the absorption rate of ammonia needs to be controlled above 98%.

[0035] To achieve this goal, the thermal power plant adopts four stages to absorb SO in the flue gas 2 . The first stage washes the flue gas with water, the inlet temperature of the wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com