Mechanical device for conveying workpieces of machine tool, pavement conveying device and method, and workpiece support used for machine tool

A mechanical device and ground conveying technology, which is applied in the field of workpiece road conveying, transporting plate-shaped workpieces, and mechanical devices for plates. It can solve the problems of high investment cost and consumption, achieve stable and uniform support, and simplify the handling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

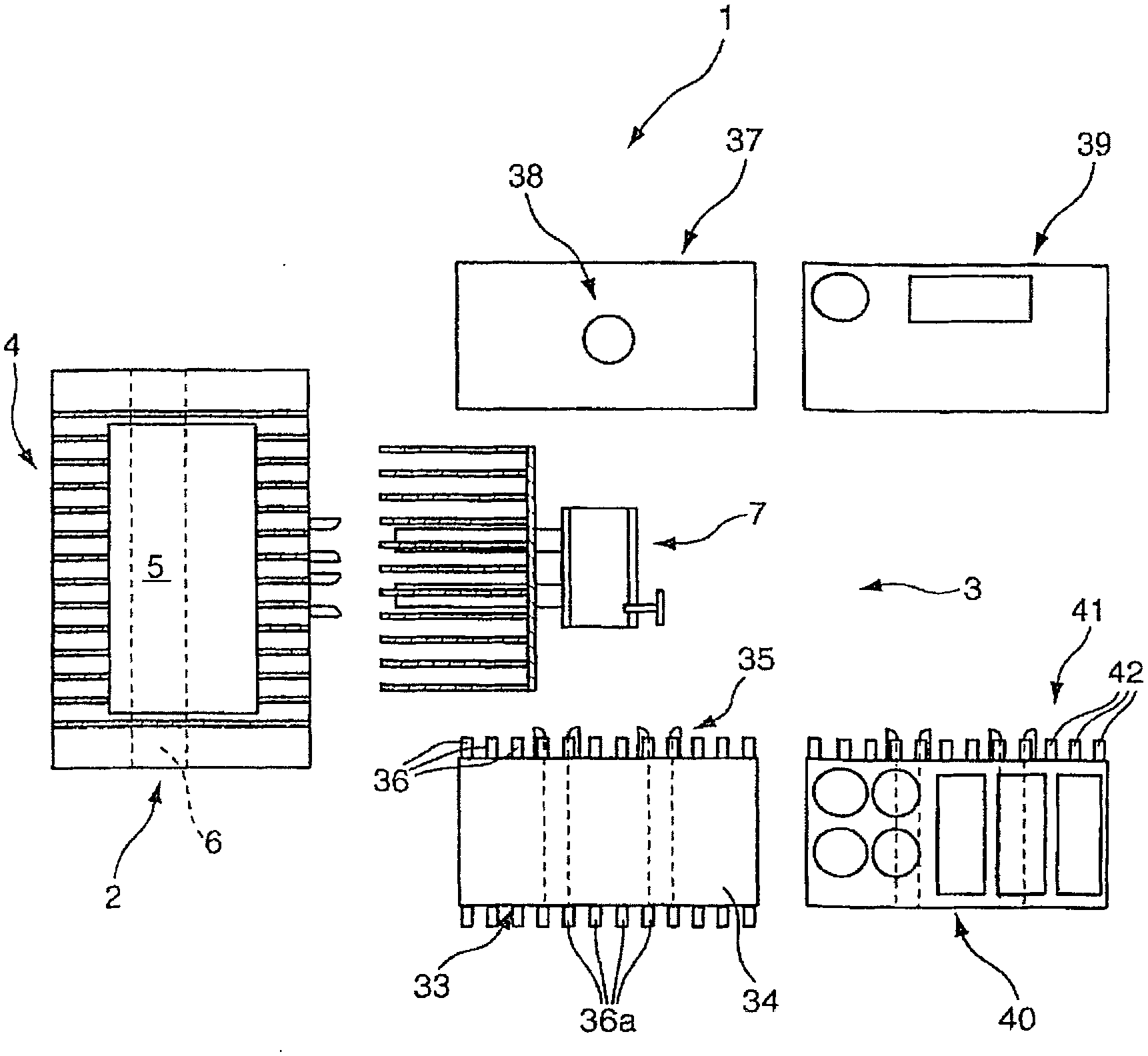

[0050] figure 1 A machine tool arrangement 1 is shown which comprises a machine tool in the form of a laser processing machine 2 and a mechanism 3 for handling workpieces of the laser processing machine 2 . The mechanical device 3 comprises a workpiece support 4 on which a workpiece in the form of a sheet metal 5 can be supported during processing by the laser processing machine. A laser processing head (not shown) is used for workpiece processing, which can be moved on a guide system 6 indicated by dashed lines.

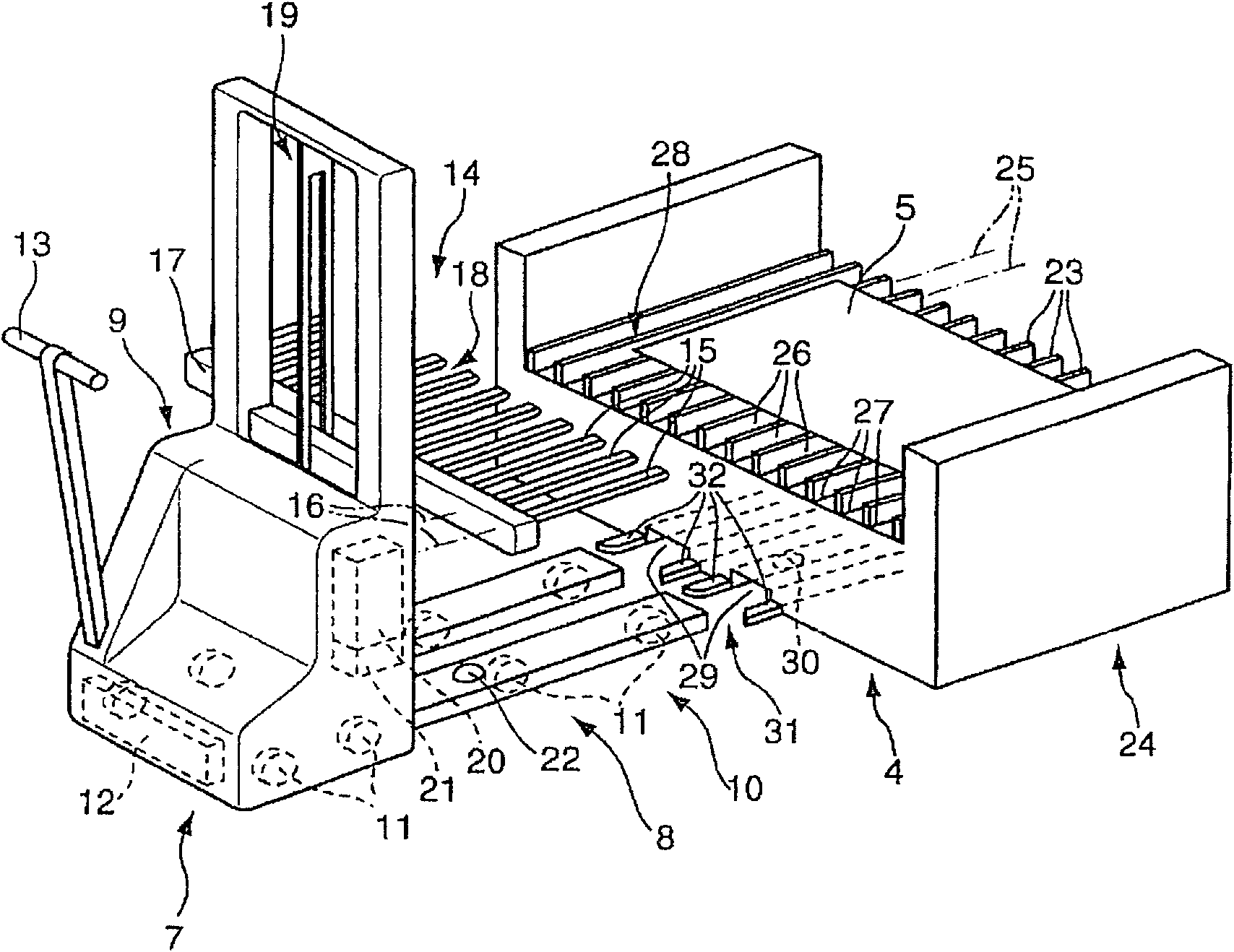

[0051] Furthermore, the mechanism 3 has a floor conveyor in the form of a shuttle 7, which figure 1 Arranged next to the workpiece support 4. next with the help of figure 2 The configurations of the workpiece support 4 and the shuttle 7 will be described in detail.

[0052] according to figure 2 The reciprocating vehicle 7 is provided with a running frame 8 on the underside, which has two running frame profiles 10 protruding laterally relative to the base bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com