Pulper with torque motor

A pulper and electric motor technology, applied to mixers with rotating stirring devices, mixers, mixer accessories, etc., can solve the problems of serious cost maintenance, increase the floor area of the pulper, etc., and achieve the goal of reducing damage risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

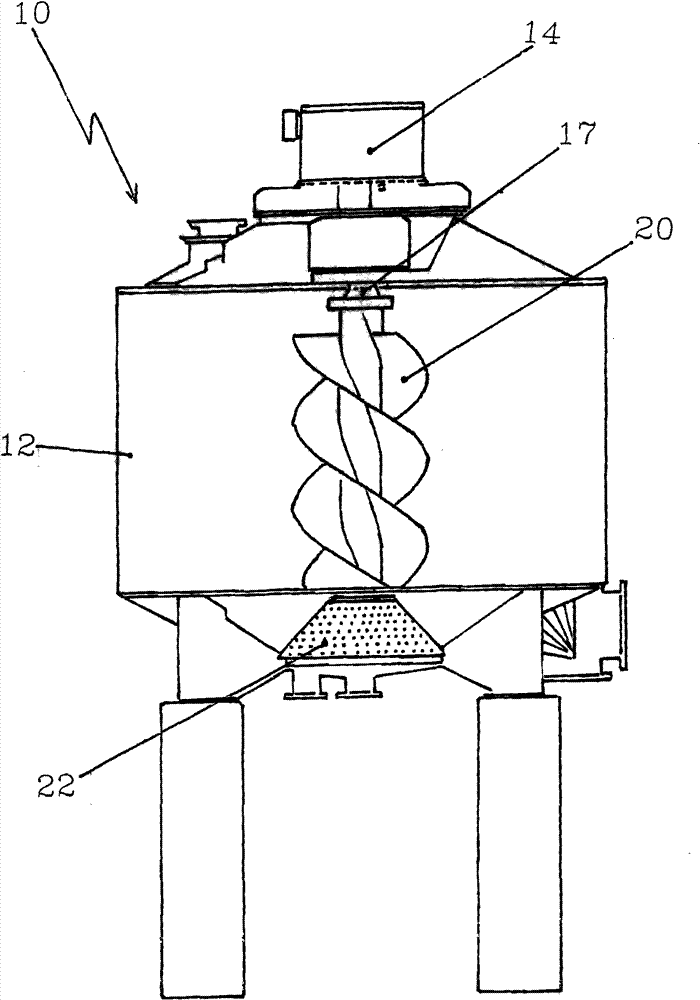

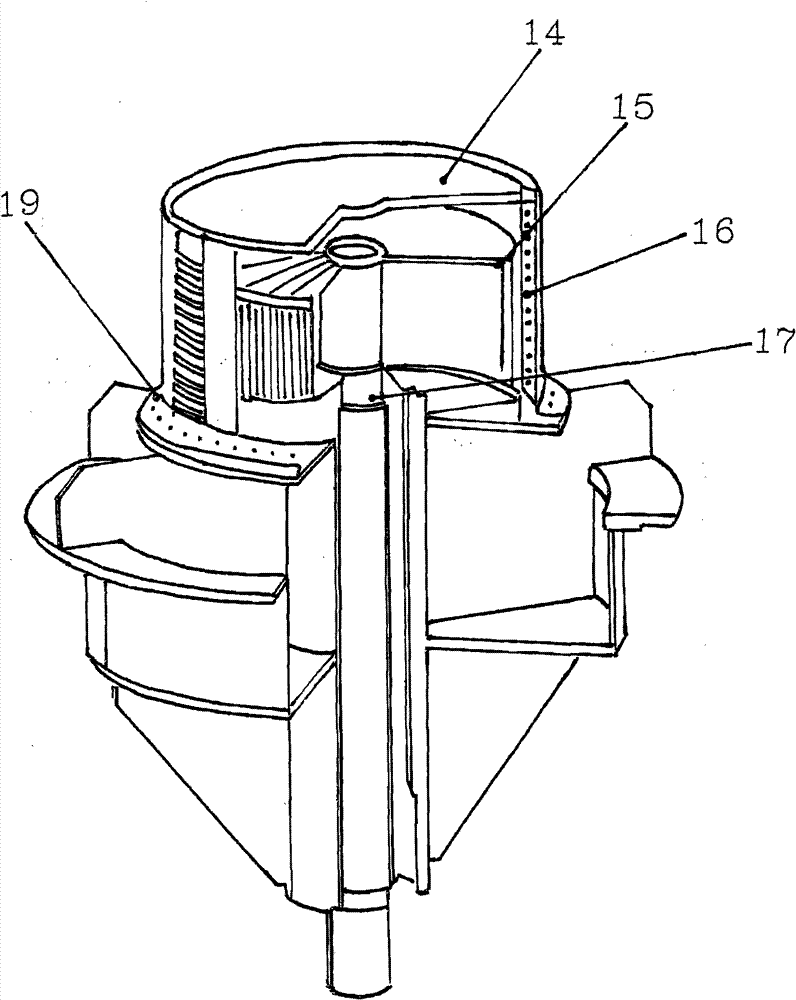

[0023] now refer to figure 1 , a pulper generally designated by reference numeral 10 is shown in the figure. The pulper rotor 20 is housed, centrally mounted, in a cylindrical pulper housing 12, the bottom of which adjoins a screen 22 which allows only sufficiently ground and dissolved material to pass through. The rotor 20 is powered by means of a three-phase synchronous motor whose motor housing 14 is centrally located on the top of the pulper housing 12 and connected by a flange 19 (see figure 2 ) to the pulper housing. The bottom of the pulper is connected to a discharge member for removing the pulper contents.

[0024] now refer to figure 2 , shows on an enlarged scale how the torque motor is flanged to the pulper housing by means of a flange 19 . The stator 16 and the rotor 15 of the motor can be seen in a section through the motor housing 14 . In the connecting portion 17 the motor output shaft is connected to the shaft of the pulper rotor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com