Milling and paving double-purpose machine

A milling and dual-purpose technology, applied in the field of dual-purpose machines, can solve the problem of low operation accuracy, and achieve the effects of flexible use, small size, and easy disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

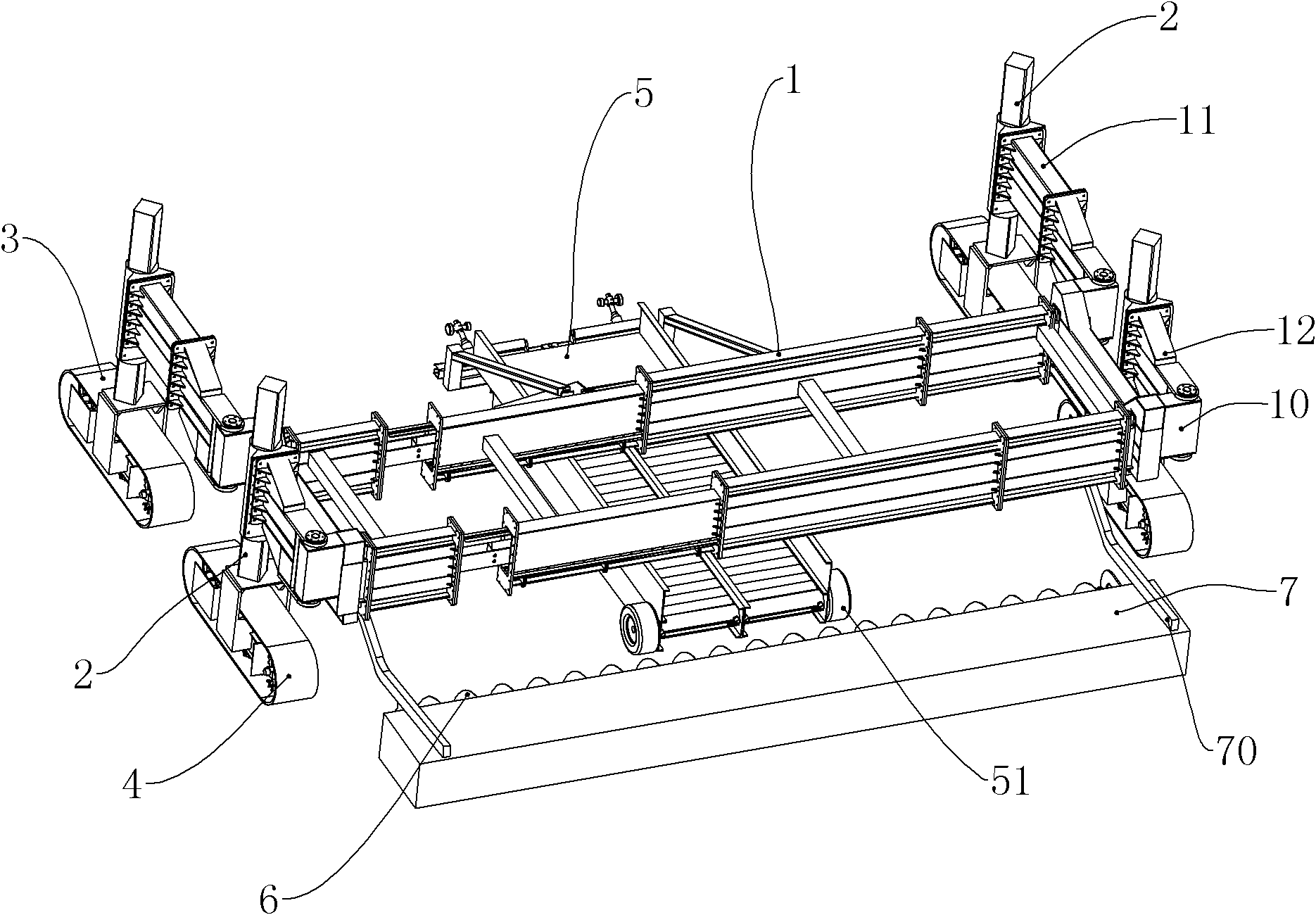

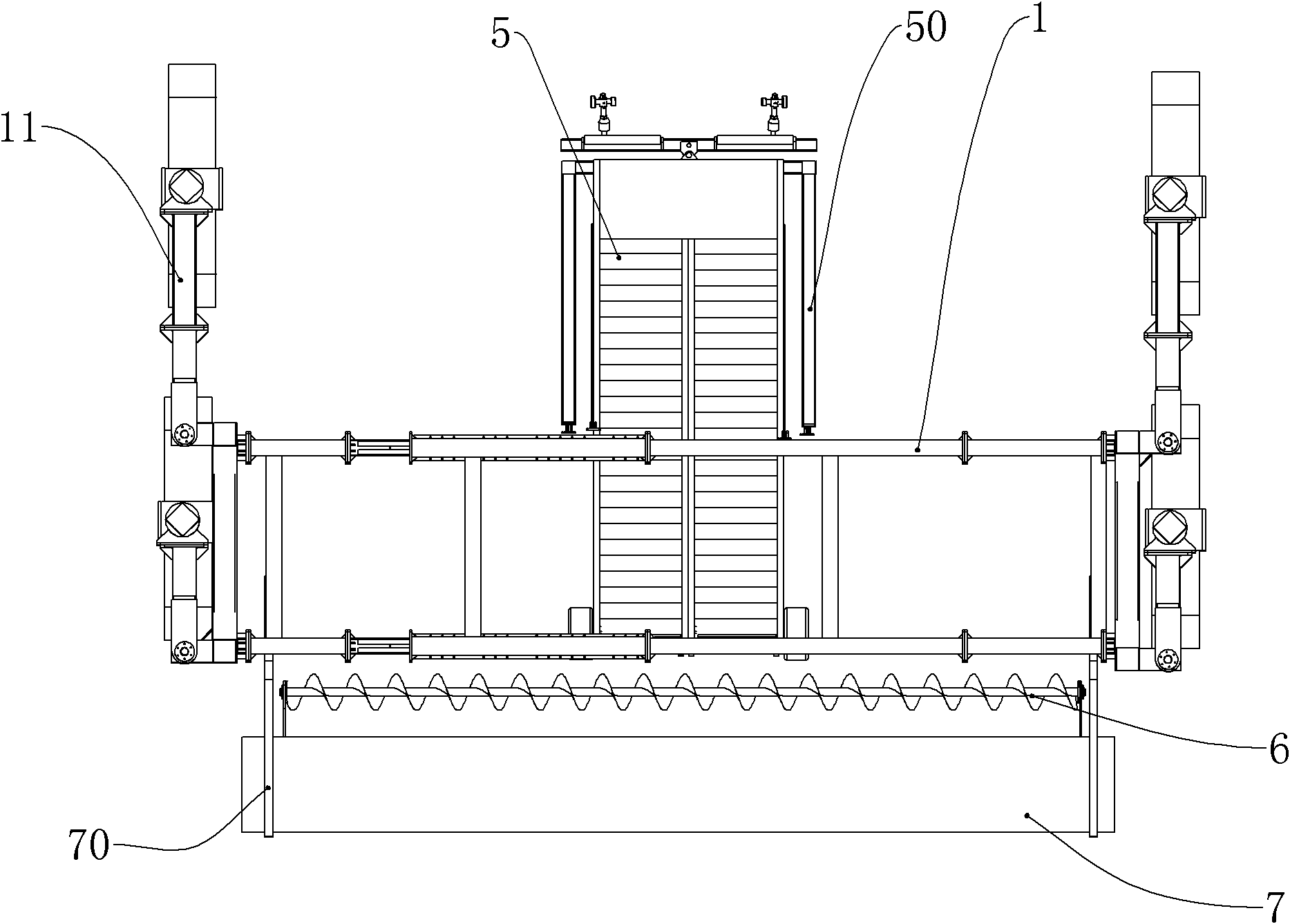

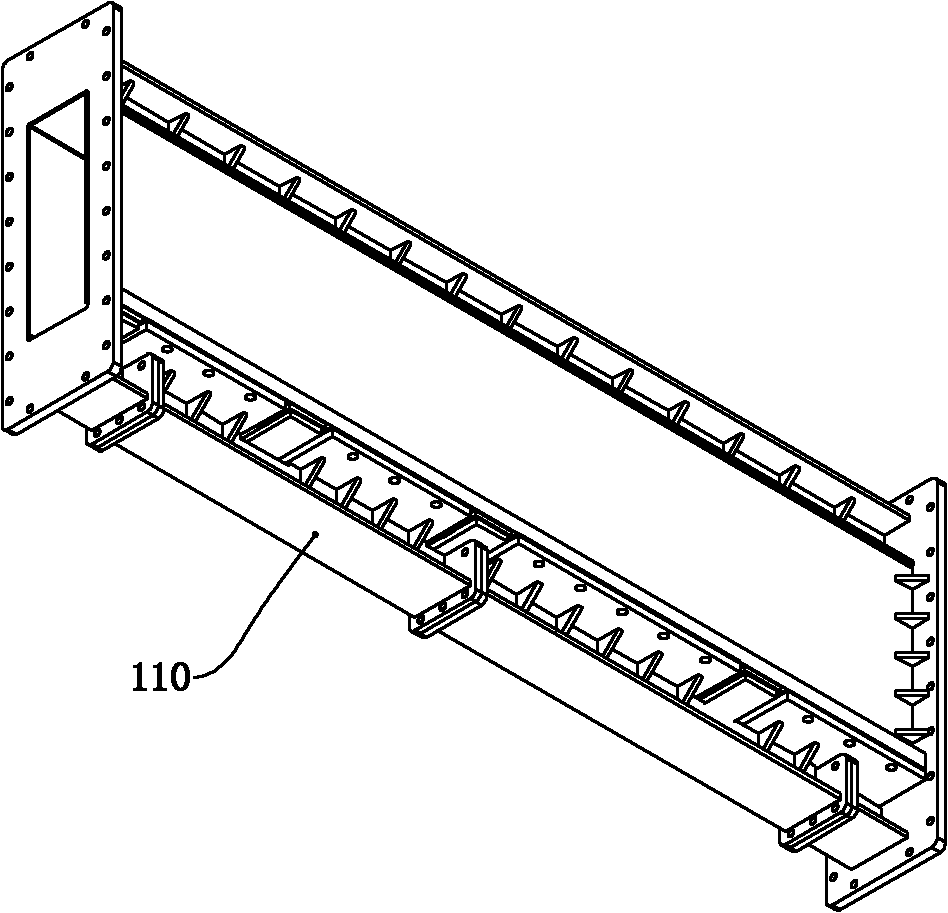

[0037] Such as figure 1 and figure 2 As shown, the main frame 1 of the milling, planing and paving machine of the present invention mainly includes a front beam, a rear beam, and side beams connected to the front beam and the rear beam installed at the left and right ends of the front beam and the rear beam, on the main frame 1 A power assembly, an operation console, hydraulic pipes, cables, etc. are installed, and leveling sensors are installed on both sides of the main frame 1. The installation and connection relationship of these parts is the same as that of the prior art, and those of ordinary skill in the art can The mechanical design manual or technical specifications and construction requirements shall be designed accordingly, and details will not be repeated here. For ease of description, the direction perpendicular to the milling and paving machine of the present invention when walking under the paving working state is defined as the transverse direction, and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com