Wall-mounted furnace canner motor pump with automatic exhaust device

A technology of automatic exhaust and shielding electric pump, which is applied to the components of pumping device for elastic fluid, driving pump, pump device, etc., to achieve the effect of improving performance, reducing energy consumption and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

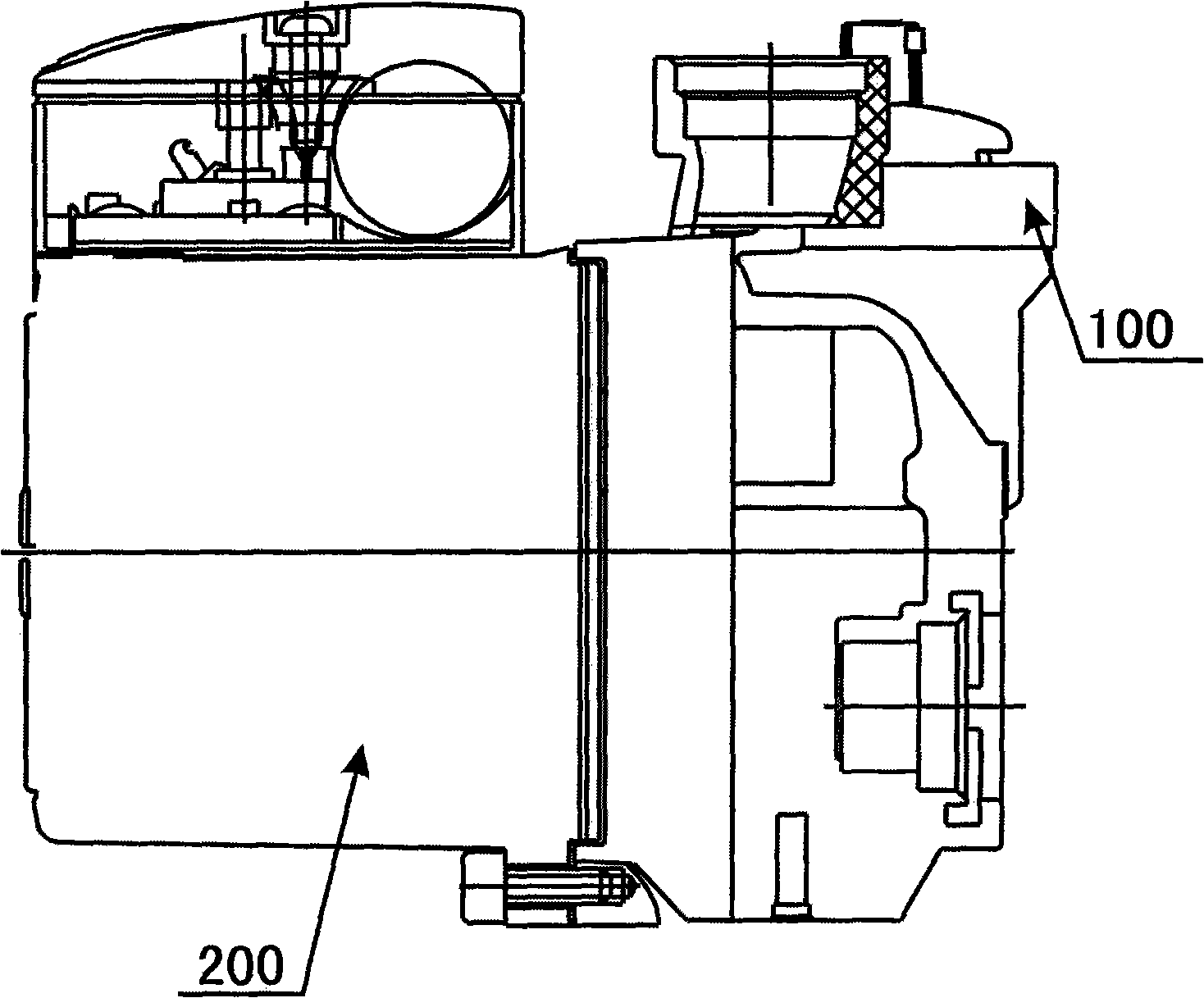

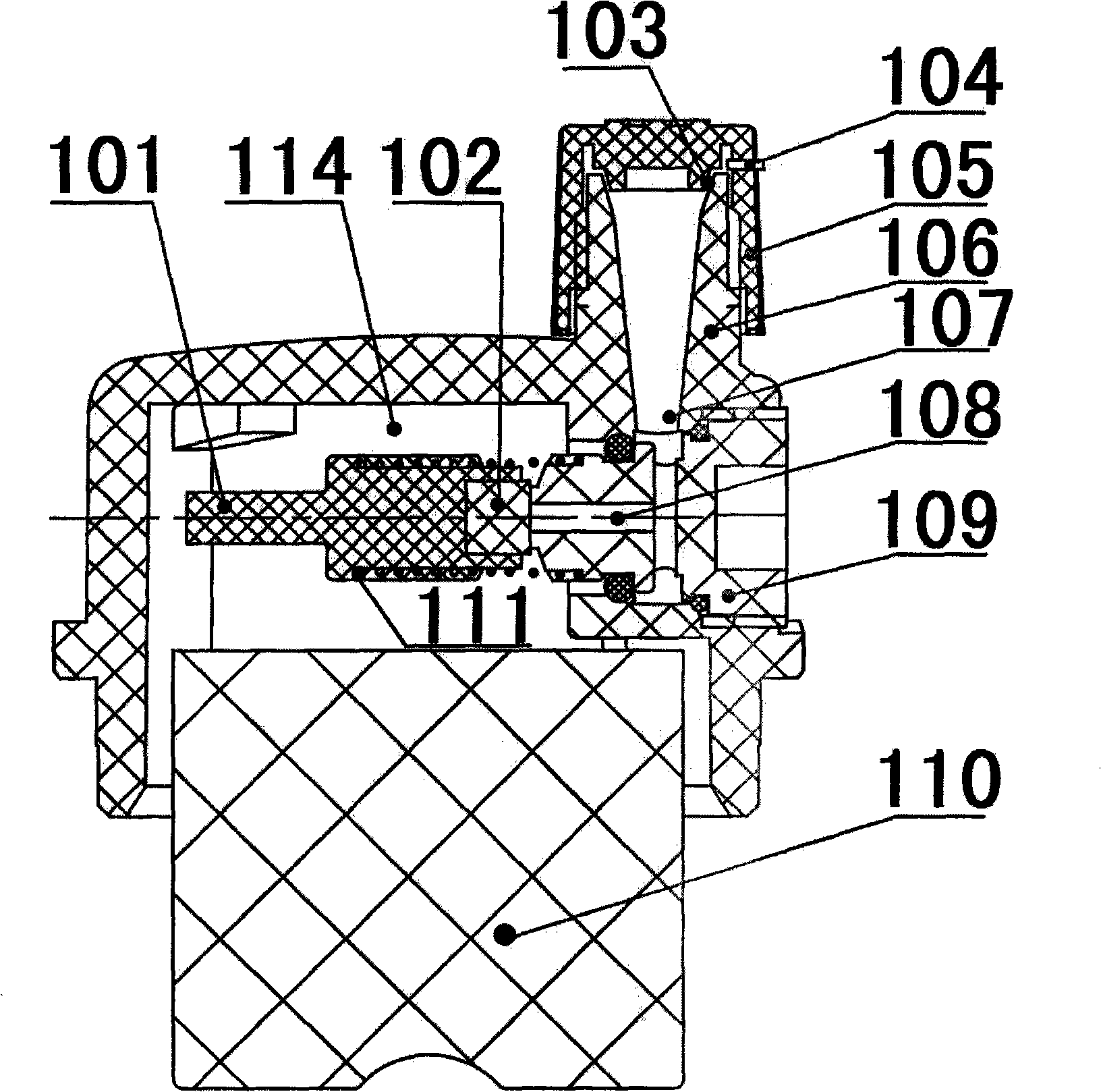

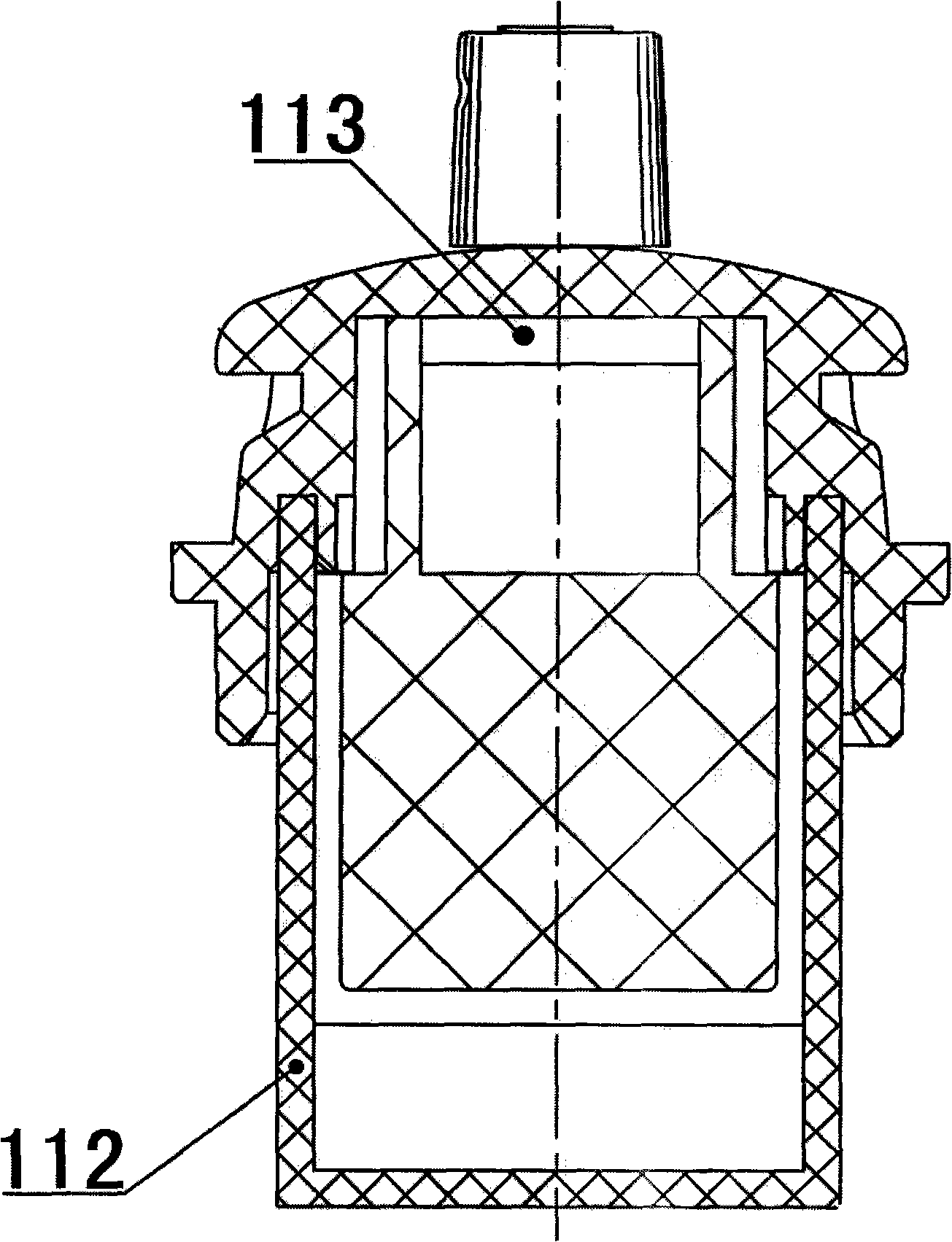

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0021] The present invention solves the problem of inconvenient operation and difficulty in controlling the leakage of water in the electric pump in the existing shielded electric pump for wall-hung boilers, which needs to manually discharge the gas in the pipeline and inside the electric pump during the working process, and easily damages other electrical appliances, causing safety and safety problems. To solve the problem of environmental pollution, a shielded electric pump for a wall-hung boiler with an automatic exhaust device is provided.

[0022] The design principle of the canned pump provided by the present invention is to use the density of the gas is much lower than that of water, and it is always at the top, while the installation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com