Method for manufacturing battery lighter

A battery and battery cover technology, applied in the field of daily necessities, can solve the problems of inelegant appearance, complicated structure and production process, etc., and achieve the effects of increasing the use value, facilitating the replacement of batteries, and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

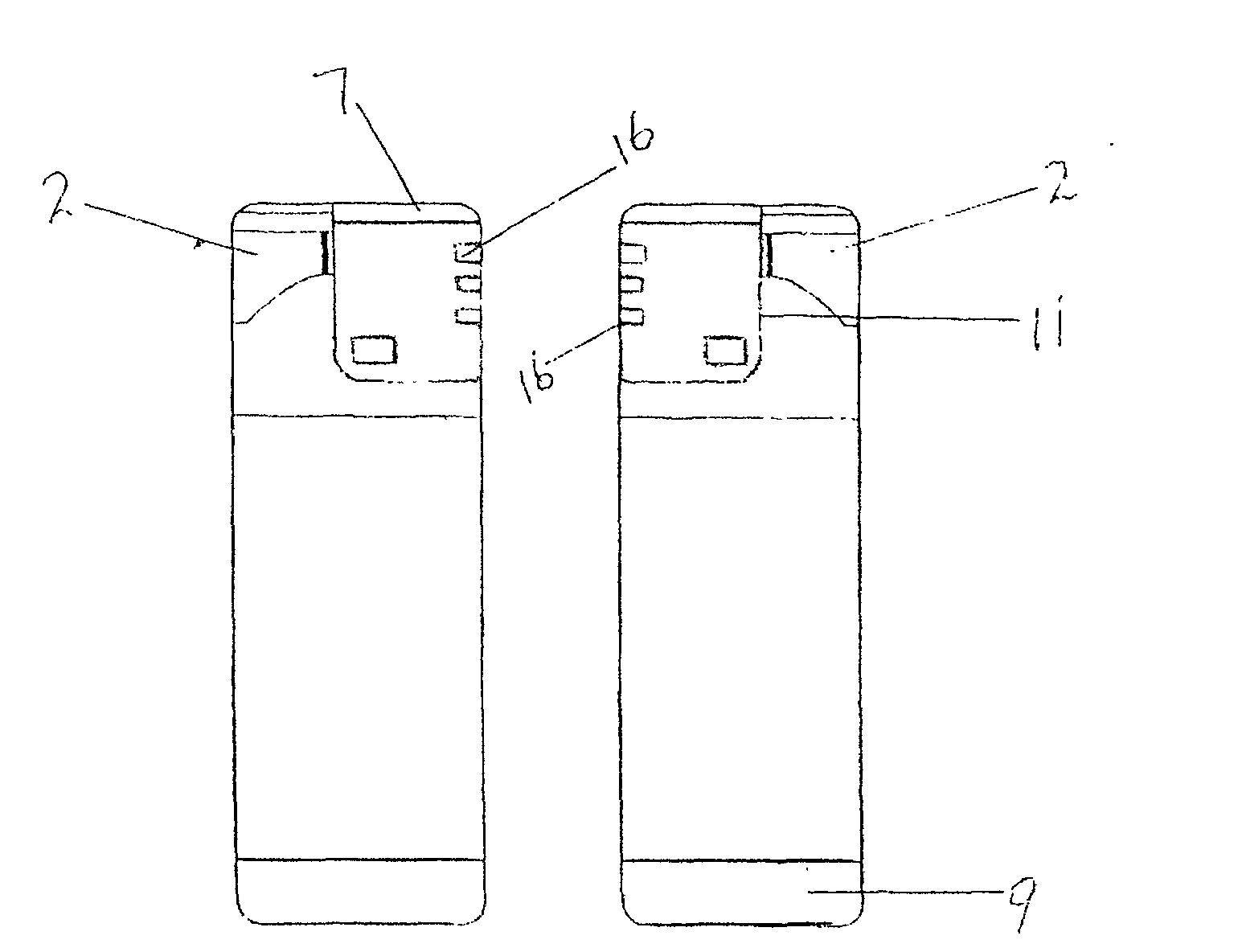

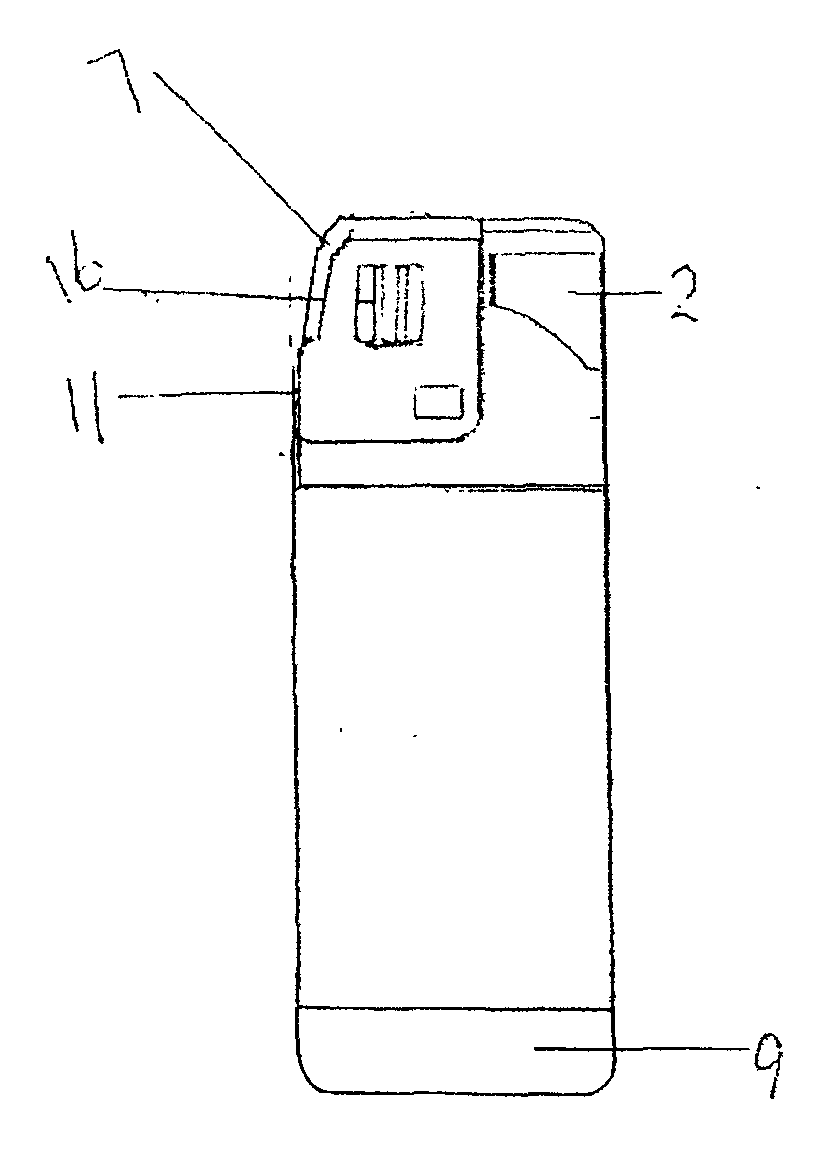

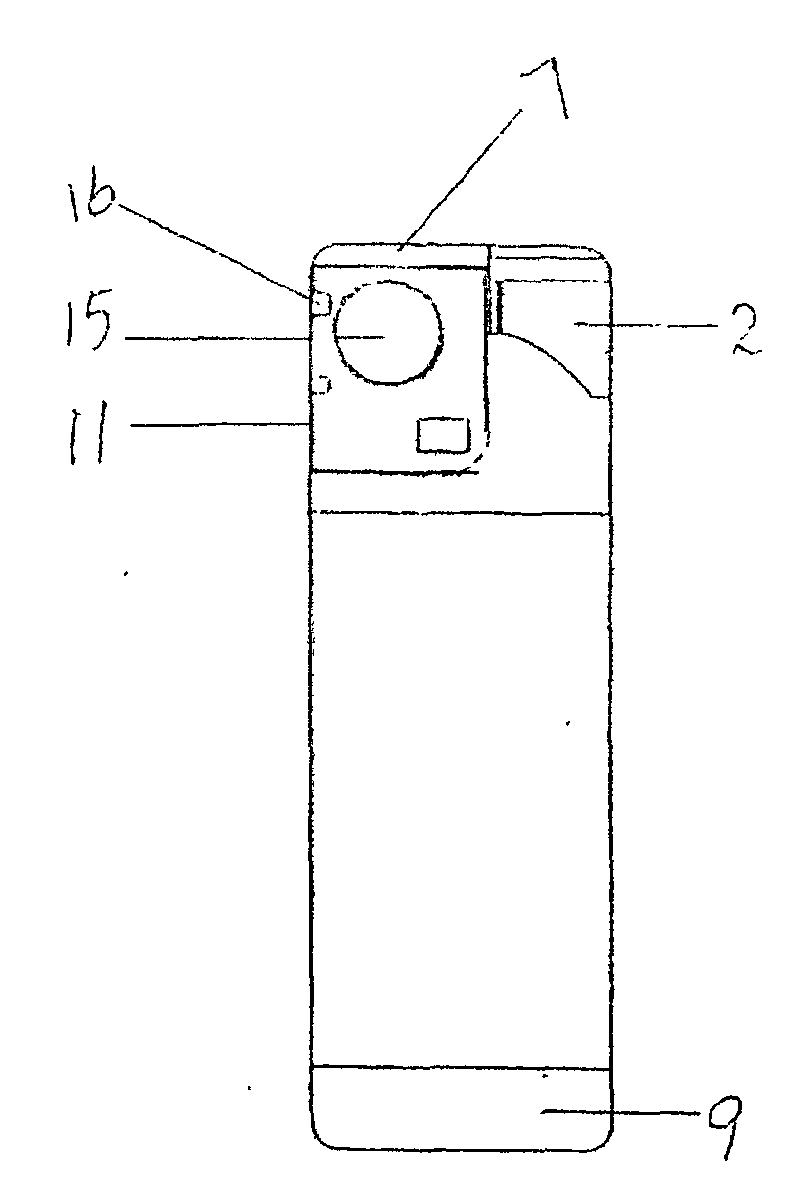

[0016] Below in conjunction with accompanying drawing and embodiment, this manufacturing method is further described:

[0017] The components of this manufacturing method are composed of a body 1, a heating device 5, a conductive wire 6, a metal sheet 4, a spring 3, a button 2, a safety cover 7, a fire cover 11, a battery 8, and a battery cover 9, wherein a battery spring is installed in the battery cover 7 14; the fire cover 11 is provided with a smoke hole 15 and a heat dissipation hole 16; the method is that the heating device 5 is firmly fixed in the body machine 1, and connected to the conductive wire 6; the conductive wire 6 contacts the metal sheet 4; the metal sheet 4 is fixed on the lower end of the button 2 It is in contact with the electrode of the battery 8; the lower end of the button 2 is set in the spring 3, and the upper part is fixed on the body 1 by the rail 10, and is connected with the safety cover 7; the safety cover 7 is connected to the top of the body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com