Pattern transfer method and mask manufacturing method

A technology of pattern transfer and production method, which is applied to the photolithographic process of the patterned surface, the photolithographic process exposure device, optics, etc., can solve the problems of consuming a lot of manpower and time, affecting production efficiency, and increasing the cost of lithography. The effect of saving production costs, improving production efficiency and reducing the number of exposures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

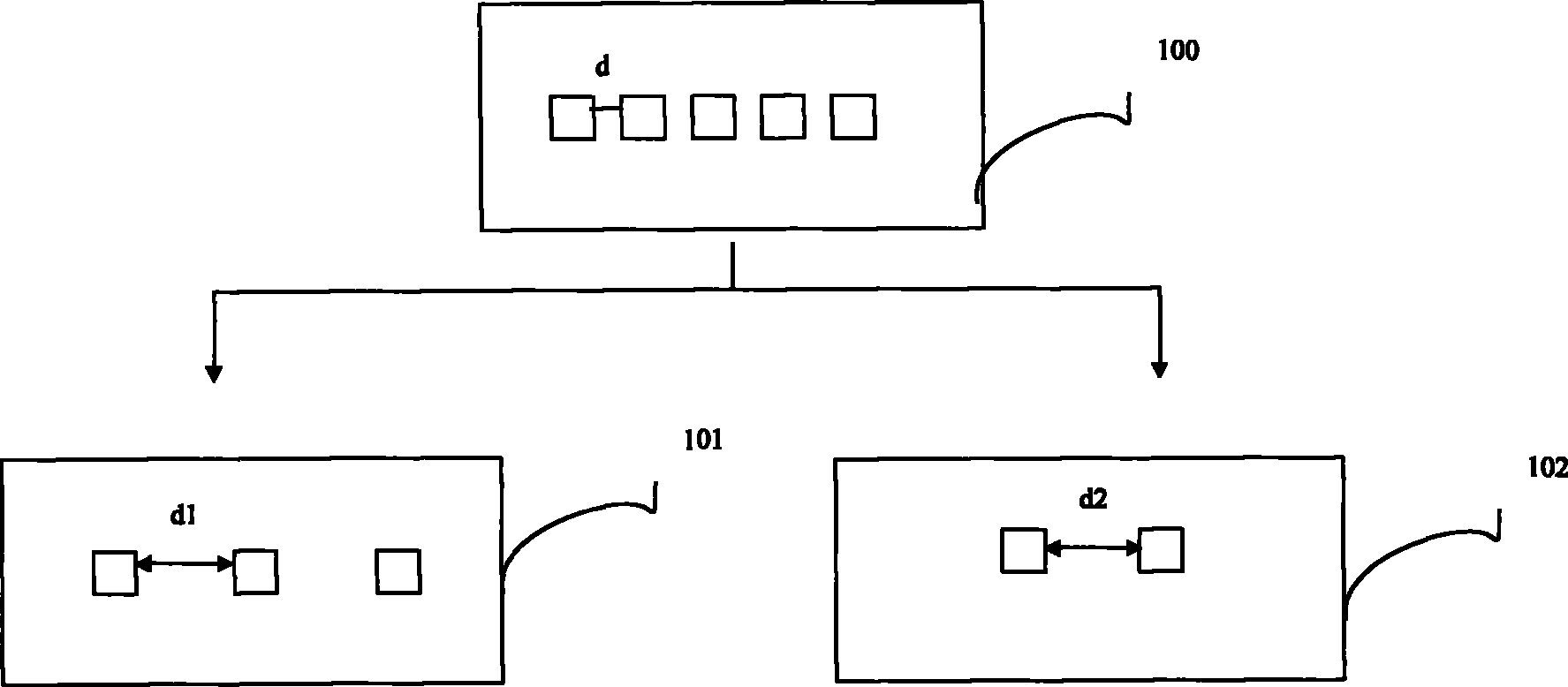

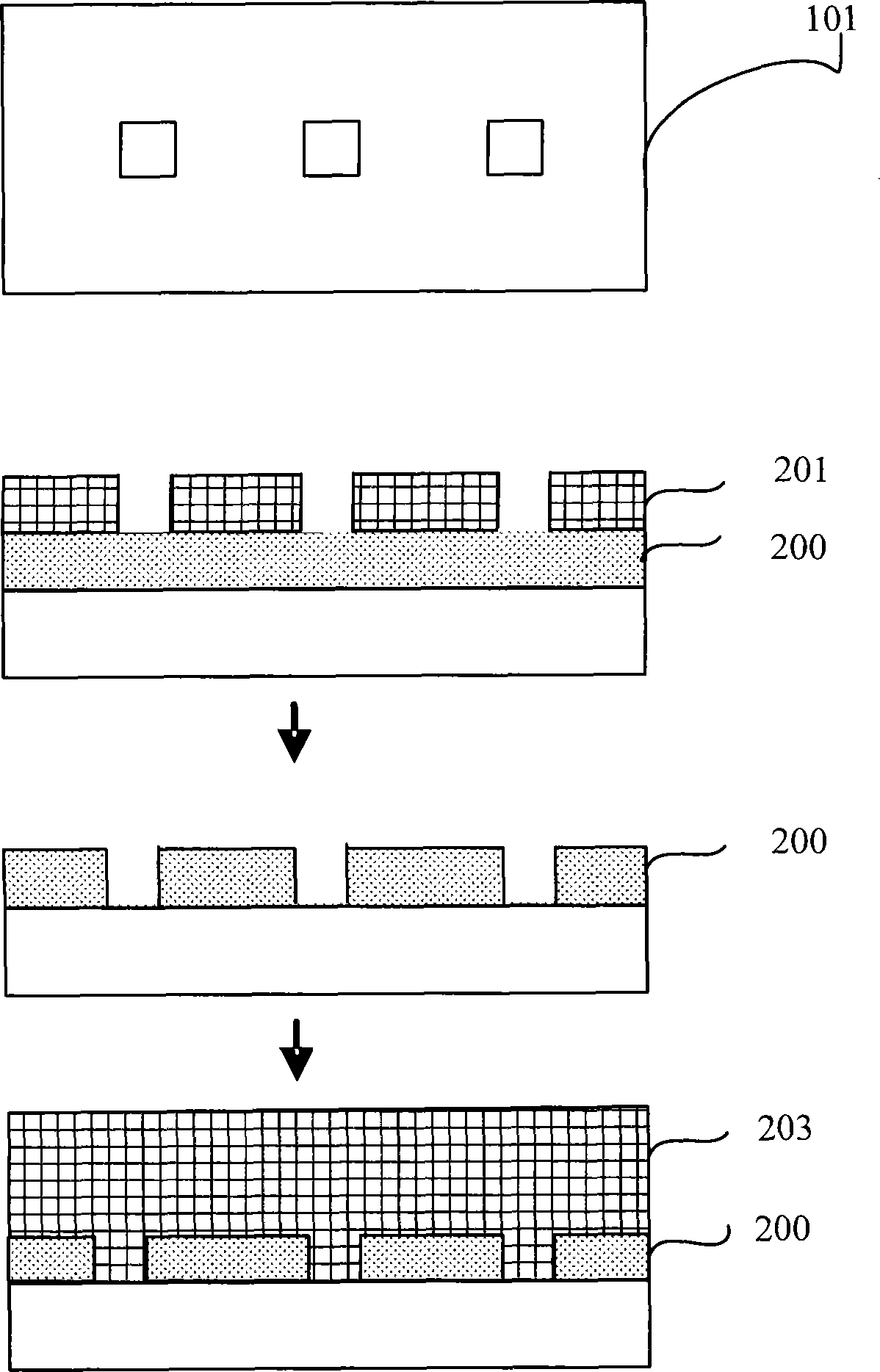

[0027] The invention provides a pattern transfer method and a mask making method, which utilize the different characteristics of the positive photoresist and the reverse photoresist, and on the basis of the existing photolithography equipment, only one exposure can be used to realize the pattern The transfer, which greatly saves manpower and time, improves production efficiency and saves production costs.

[0028] The implementation of the graphics transfer method of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

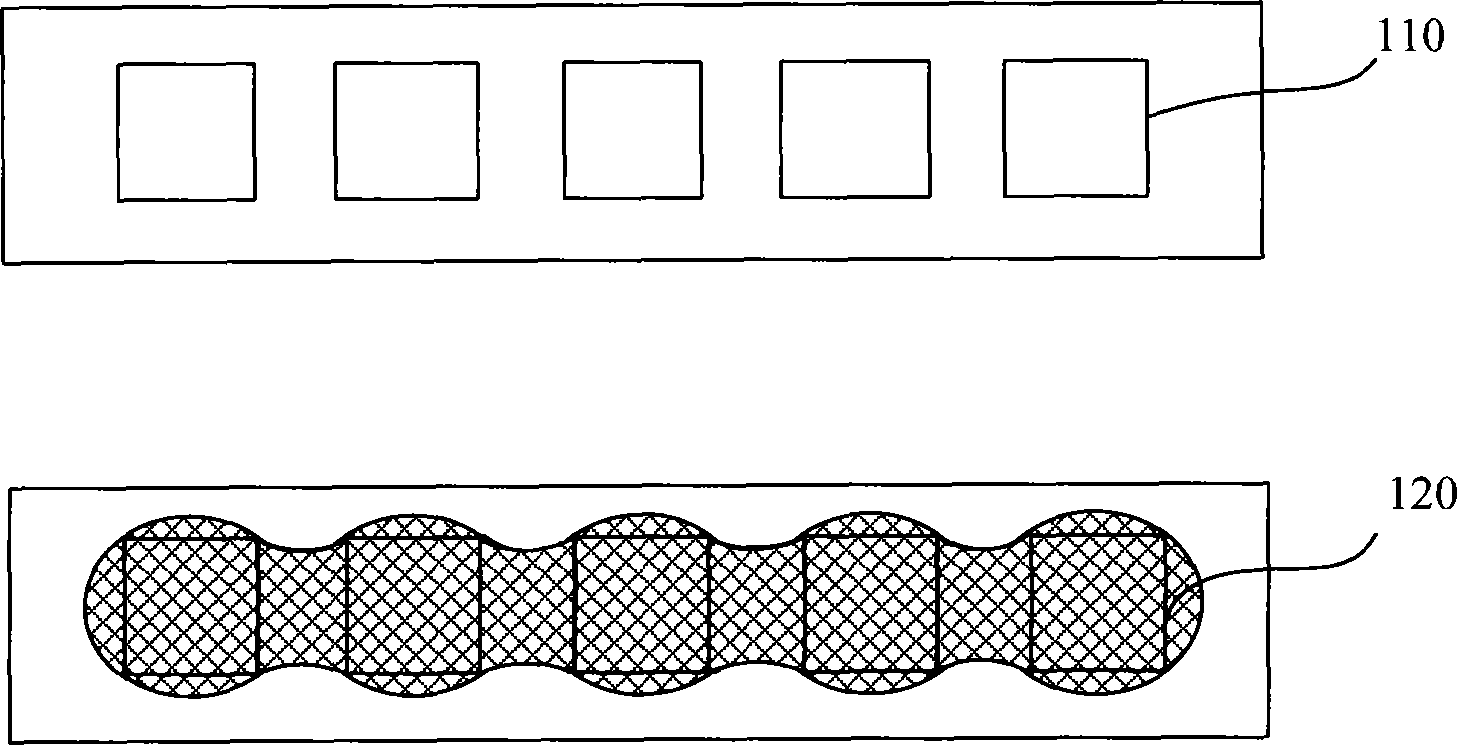

[0029] refer to Figure 5 , the present invention provides a pattern transfer method, comprising: step S1, forming a photoresist layer on a substrate, the photoresist layer at least including a positive photoresist layer and a negative photoresist layer, and a photoresist layer located between the two Between the transparent material layer, wherein, the thickness of the photoresist layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com