Automatic egg breaking machine and automatic egg breaking method

An automatic, egg-drilling machine technology, applied in applications, food preparation, food science, etc., can solve the problems that the poking holes cannot be too large, the egg liquid flows out slowly, and the egg liquid is easy to stick, etc., with fast speed and simple operation , the effect of meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

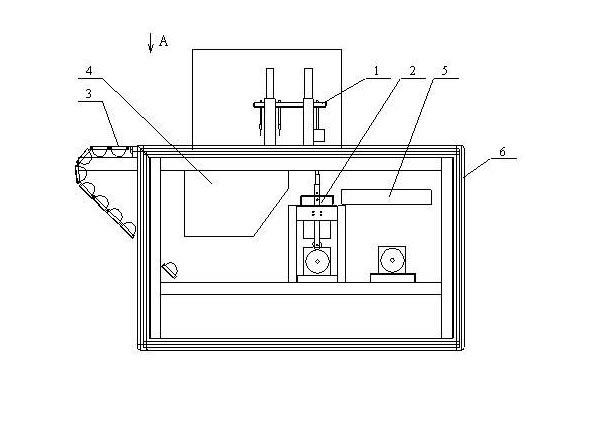

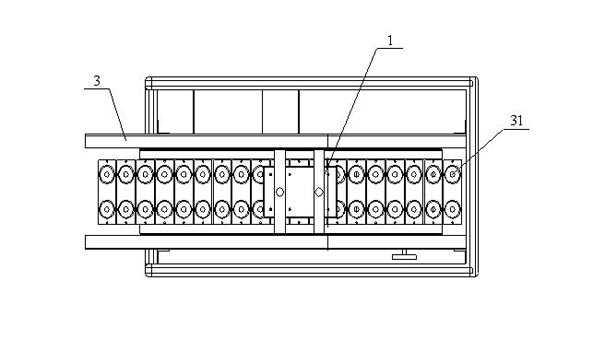

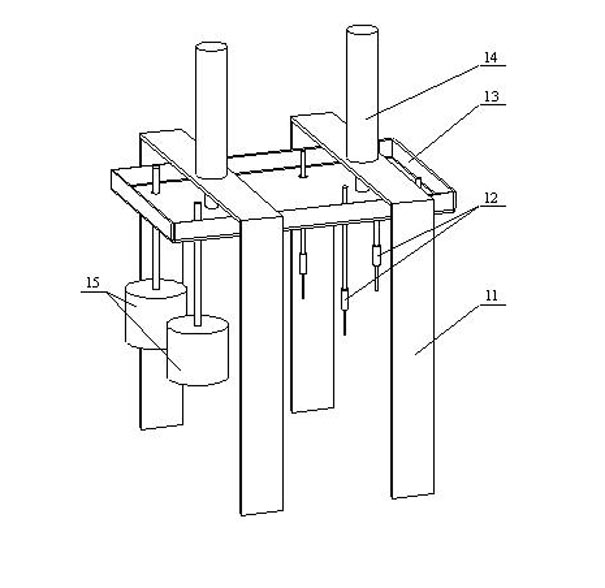

[0039] combine figure 1 , figure 2 , image 3 and Figure 4 Illustrate the embodiment of the automatic egg breaking machine of the present invention, it comprises frame 6, is arranged on the egg feeding device 3 on frame 6, is positioned at egg mold 31 below and is used for drilling the egg shell bottom of raw egg wherein The device 2, the egg punching device 1 located above the egg mold 31 for punching out the raw eggs drilled by the egg drilling device 2 and the corresponding egg liquid bucket 4 below it for receiving egg liquid. The egg feeding device 3 is a sprocket chain transmission device, and the chain is provided with a number of egg modules connected in series, each egg module includes two egg molds 31, and the egg drilling device 2 includes a bracket 26, which is arranged on the bracket 26. And the egg-drilling machine that can move up and down relative to it, the egg-drilling machine comprises an egg-drilling motor 24, two egg hole drills 21 that are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com