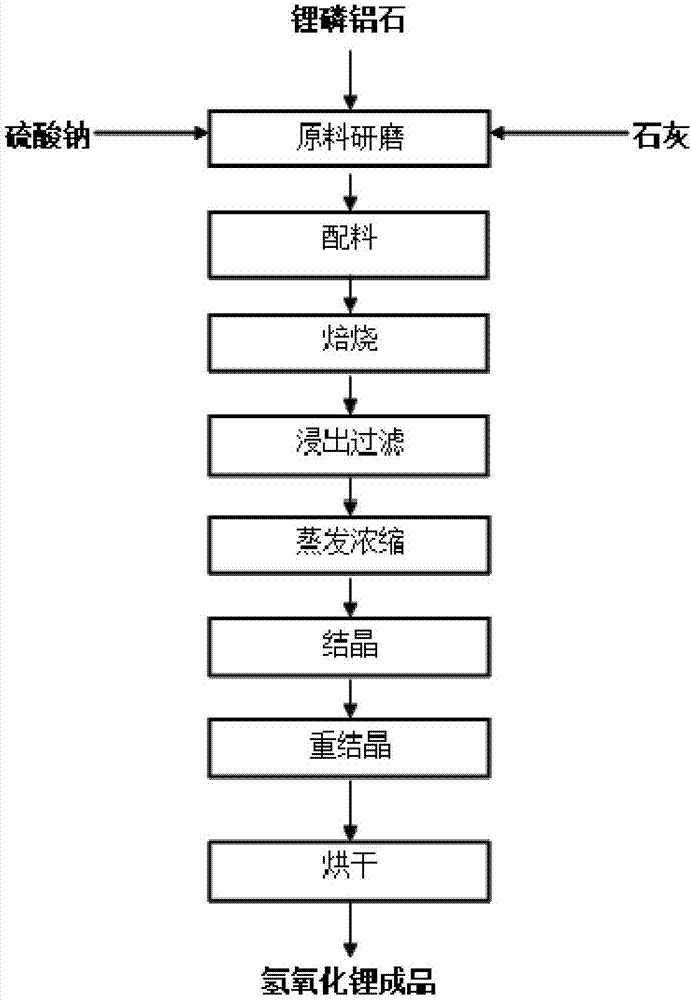

Method for extracting lithium hydroxide from amblygonite through lime method

A technology of lithium hydroxide and lithium phosphate aluminum oxide, which is applied in the direction of lithium oxide; The effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of embodiment of the process of extracting lithium hydroxide from lithium phosphorite by lime method, concrete operation is as follows.

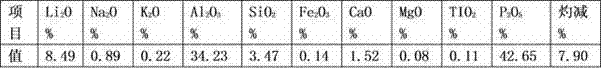

[0036] S1 Grinding of raw materials, grinding lithium phosphate ore and lime to 200 mesh respectively.

[0037] S2 ingredients, uniformly mix lithium phosphate and lime at a ratio of 1: 3.5 to form a raw material, add 200g lithium phosphate ore powder into a porcelain crucible, then add 700g lime powder into a porcelain crucible, and mix evenly by hand.

[0038] S3 roasting, high-temperature roasting of the raw material to form clinker, put the raw material into the muffle furnace, turn on the heating switch, set the maximum temperature to 1050°C, heat up, wait until the temperature in the furnace reaches 1050°C, and then continue the reaction for 20 Minutes, after the reaction time is up, turn off the heating switch and wait for it to cool to room temperature.

[0039] S4 leaching and filtering, firstly grind the clinker, gri...

Embodiment 2

[0045] A kind of embodiment of the process of extracting lithium hydroxide from lithium phosphorite by lime method, concrete operation is as follows.

[0046] S1 Grinding of raw materials, grinding lithium phosphate ore and lime to 180 mesh respectively.

[0047] S2 ingredients, uniformly mix lithium phosphate and lime at a ratio of 1: 3 to form a raw material, add 200g lithium phosphate ore powder into a porcelain crucible, then add 600g lime powder into a porcelain crucible, and mix evenly by hand.

[0048] S3 roasting, roasting the raw material at high temperature to form clinker, put the raw material into the muffle furnace, turn on the heating switch, set the maximum temperature to 1000°C, heat up, wait until the temperature in the furnace reaches 1000°C, and then continue the reaction for 30 Minutes, after the reaction time is up, turn off the heating switch and wait for it to cool to room temperature.

[0049] S4 leaching and filtration, firstly grind the clinker, grin...

Embodiment 3

[0055] A kind of lime method extracts the technology of lithium hydroxide from lithium phosphate aluminum, comprises the steps:

[0056] S1 Raw material grinding, grinding lithium phosphate ore, sodium sulfate and lime to 180 mesh respectively;

[0057] S2 ingredients, uniformly mix lithium phosphate, sodium sulfate and lime in a ratio of 1:0.2:1.5 to form a raw meal, take 500g lithium phosphate ore powder and add it to a porcelain crucible, then weigh 100 grams of sodium sulfate powder and 750 Add 1 gram of lime powder into a porcelain crucible and mix by hand;

[0058] S3 roasting, roasting the raw material at high temperature to form clinker, put the raw material into the muffle furnace, turn on the heating switch, set the maximum temperature to 1000°C, heat up, and wait for the temperature in the furnace to reach 1000°C, then continue the reaction for 30 Minutes, after the reaction time is up, turn off the heating switch and wait for it to cool to room temperature.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com