Tower tray provided with rectangular combination valve

A technology of combining valves and trays, applied in distillation separation, fractionation, chemical instruments and methods, etc., can solve the problems of increased manufacturing cost, complex processing procedures, and small operation flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

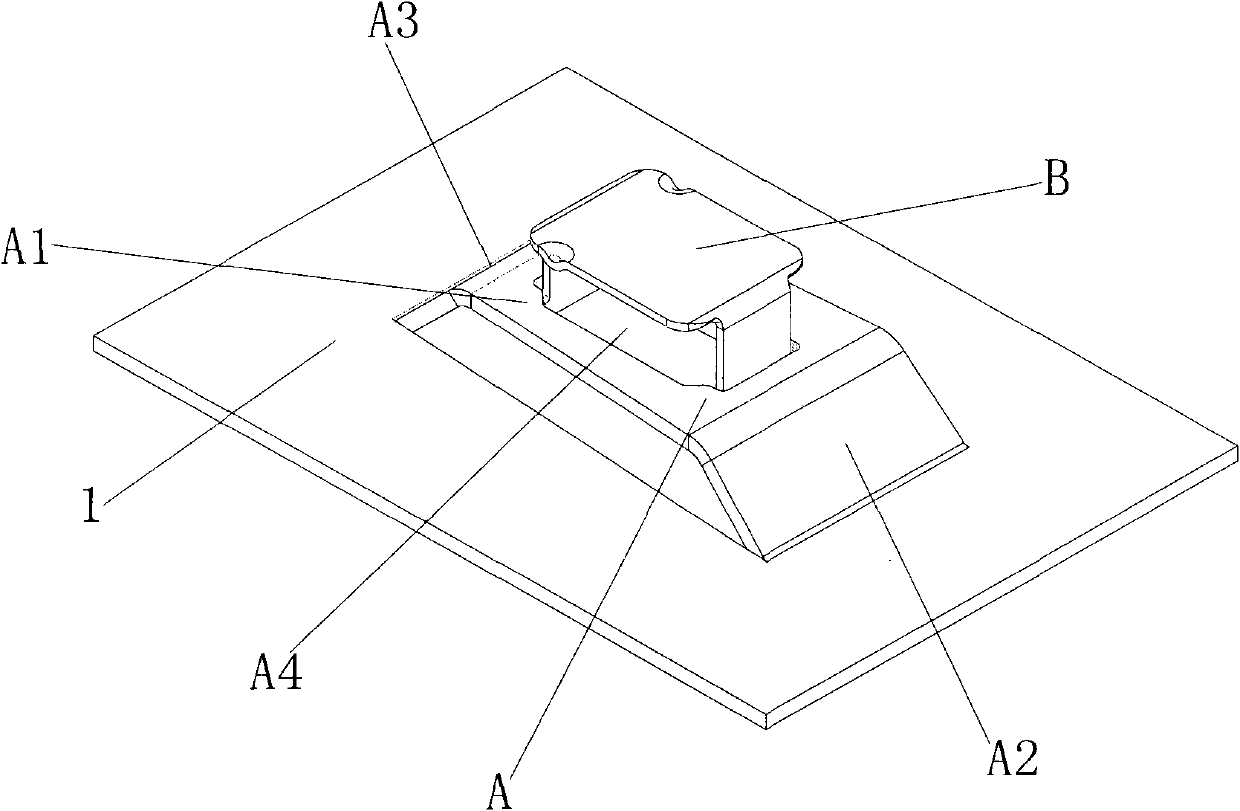

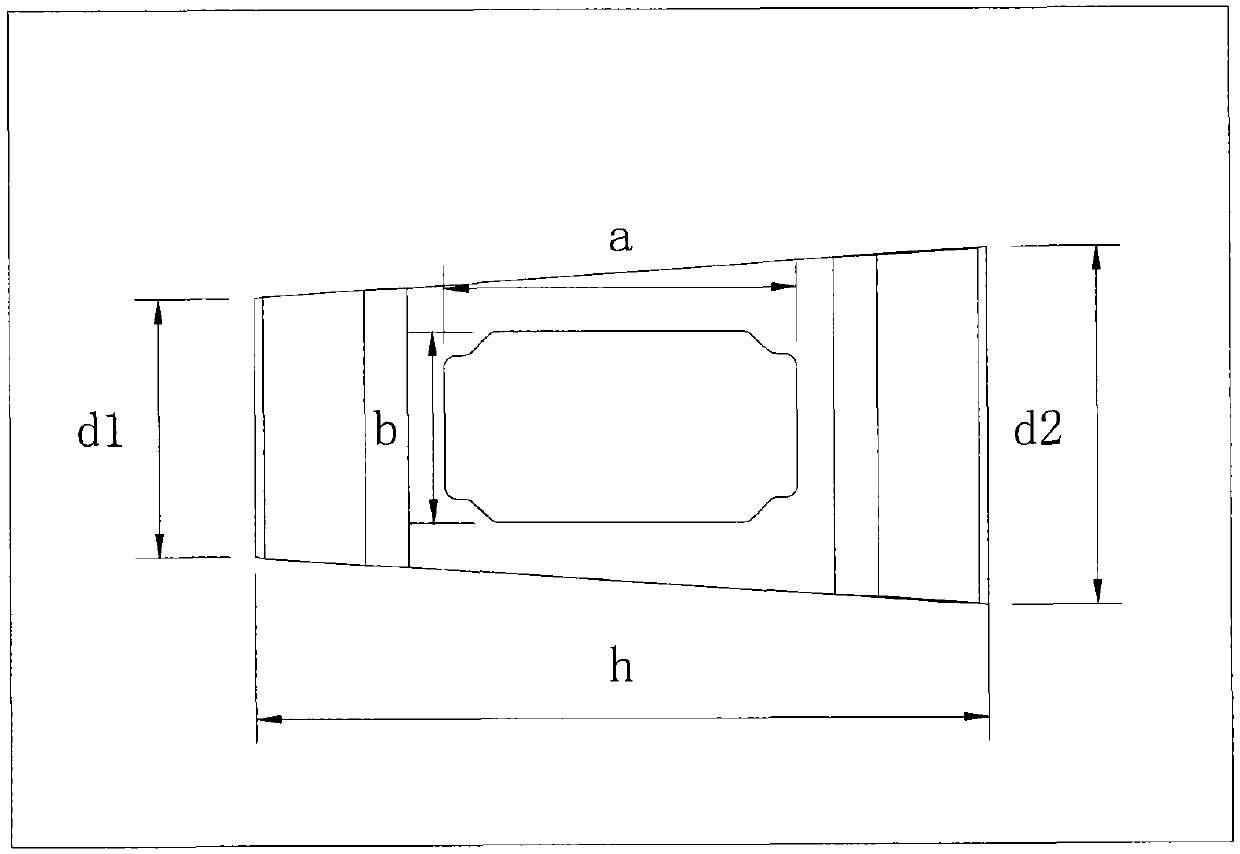

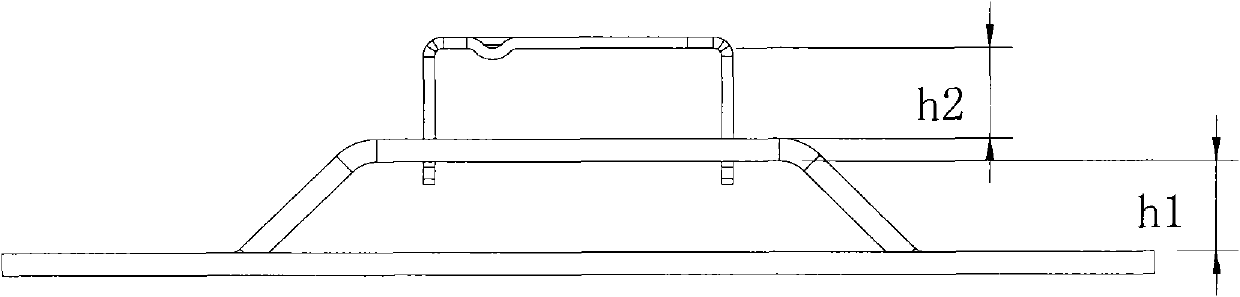

[0012] The tray that the present invention proposes is provided with rectangular combination valve, and its structure is as figure 1 As shown, it is composed of a tray plate 1, a main valve A and a sub-valve B, and the thickness l of the tray plate 1 is 1-5 mm. The mother valve A is directly stamped from the tray plate 1, and the stamped mother valve A includes the valve face A1, the wide valve leg A2 and the narrow valve leg A3, such as figure 2 As shown, the valve surface A1 of the mother valve A is an isosceles trapezoid with a square hole A4 in the middle. The upper bottom of the isosceles trapezoid is the width d1 of the narrow valve leg A3=18-25mm, and the lower bottom of the isosceles trapezoid is the wide valve. The width d2 of the leg A2=25-35mm, the height h=45-80mm of the isosceles trapezoid, the length a=25-35mm of the square hole, and the width b=15-25mm. like image 3 As shown, the lift height h1 of the main valve A is 3-7mm. like Figure 4 As shown, the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com