Roller blind system for a motor vehicle

A technology that plays a role in automobiles, applied to vehicle parts, anti-glare equipment, roofs, etc., can solve problems such as the disadvantages of levers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

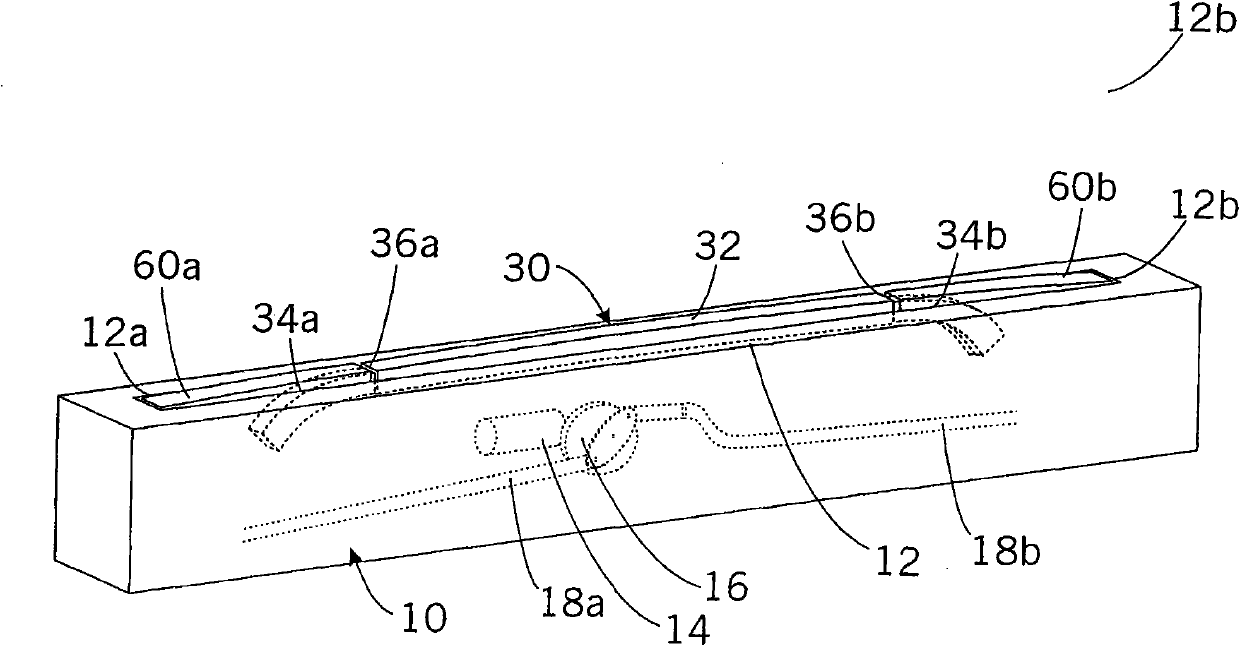

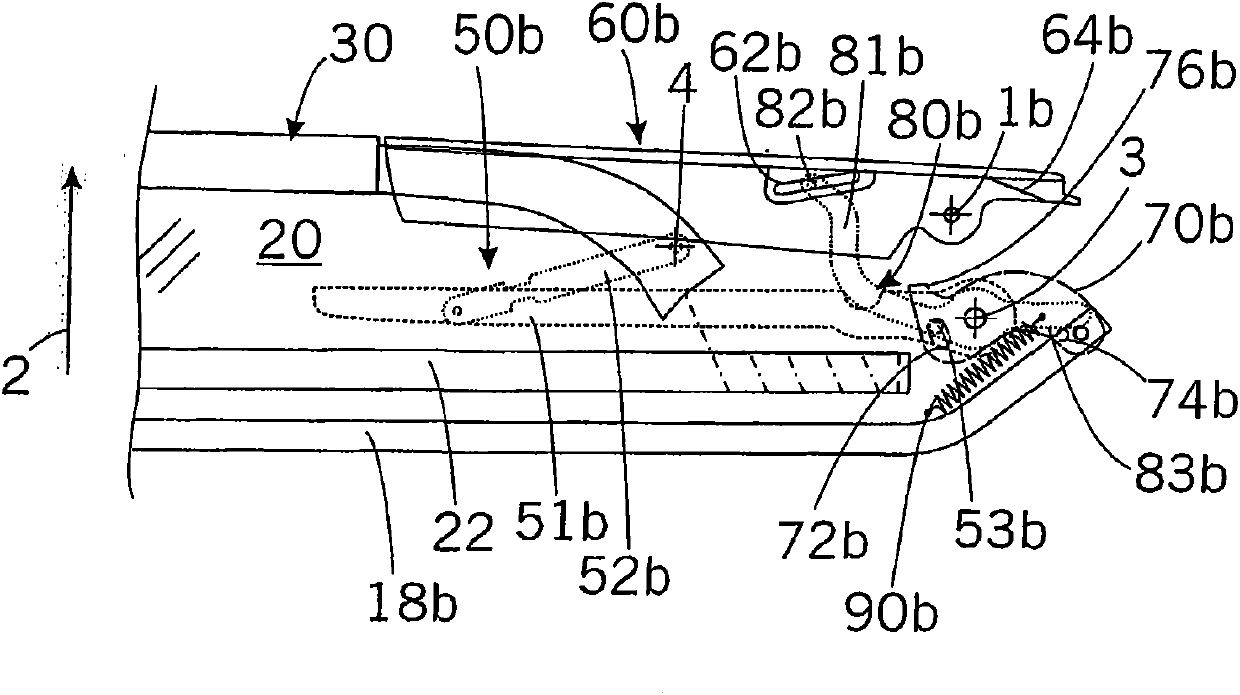

[0029] Figure 1a and 1b Shown is a protection or shading system according to the invention. Among them, in particular, the wind deflector system of a convertible car, which is arranged in the area behind the vehicle seats in order to reduce the Figure 1a The air vortex in the passenger range of the car when it is in effect.

[0030] The system has a base 10 which is arranged in a stationary manner in the vehicle. On the upper side of the base 10 an outlet slit 12 is provided, through which a planar structure 20 such as a textile planar structure or a net can be pulled out of the base 10, on the distal end of which the planar structure is equipped with an end Header 30. Arranged inside the base 10 is the Figure 1a and 1b The reel 22, not shown, is used to accept the Figure 1b Surface structure 20 in rest state. Used to connect the planar structure 20 and the end part 30 from Figure 1b The static position moves to Figure 1a The mechanical energy required for the acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com