Multi-gap discharge unit for ozone generator

A technology for ozone generators and discharge units, applied in the field of ozone generators, can solve the problems of high manufacturing difficulty, low ozone yield, and large number of discharge units, so as to reduce equipment investment and maintenance costs, and increase output and concentration , Ease of manufacture and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

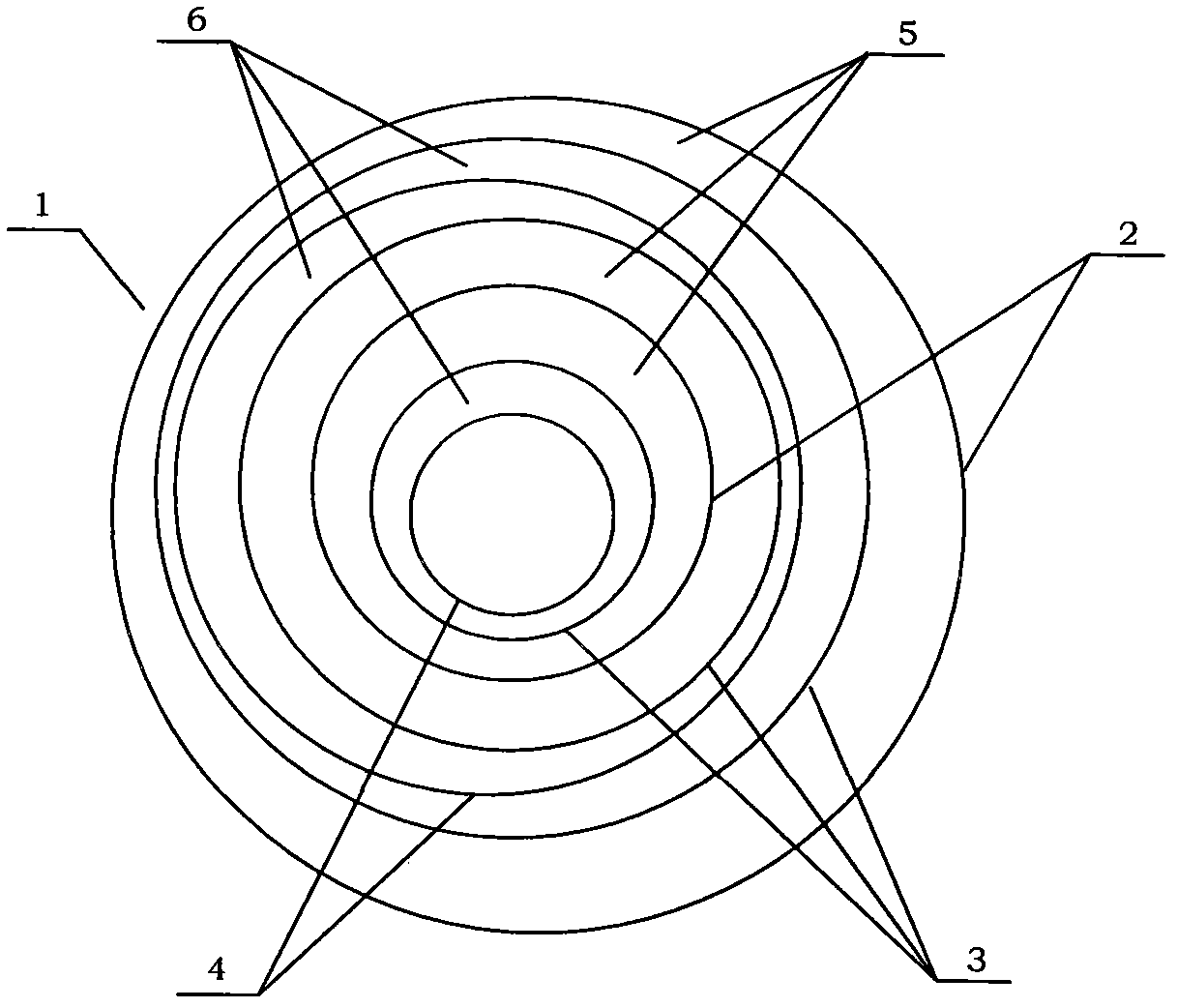

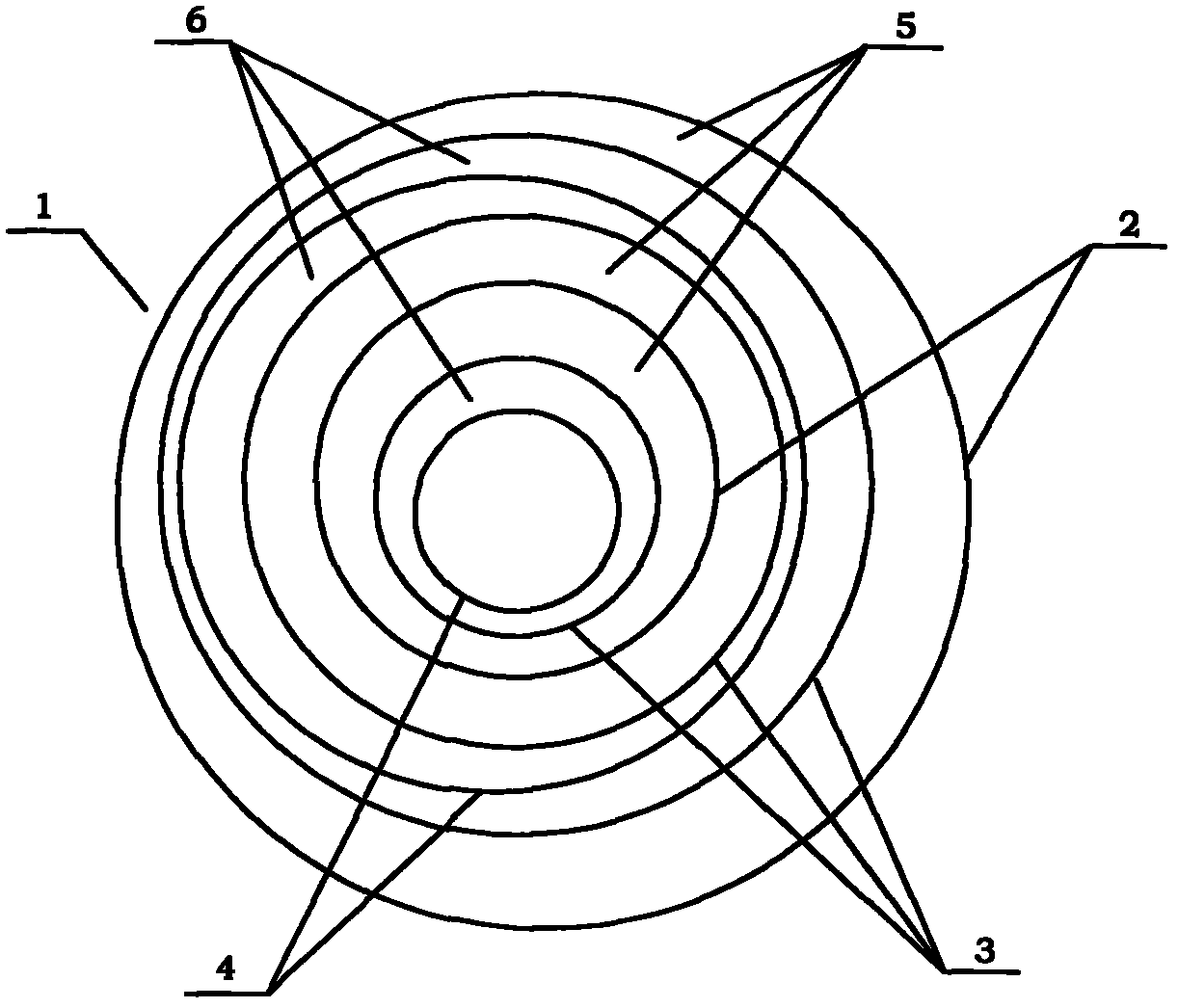

[0028] Such as figure 1 As shown, a multi-gap discharge unit 1 for an ozone generator provided by Embodiment 1 of the present invention includes a group of ring-shaped ground electrodes 2 , insulating layers 3 and high-voltage electrodes 4 installed layer by layer. In this embodiment, the number of high voltage electrodes 4 is 2, the number of insulating layers 3 is 3, and the number of ground electrodes 2 is 2. In practical applications, the numbers of ground electrodes 2, insulating layers 3 and high-voltage electrodes can be determined as required. Such as figure 1 As shown, in the discharge cell of the embodiment, the sequence from inside to outside is high voltage electrode 4 , insulating layer 3 , ground electrode 2 , insulating layer 3 , high voltage electrode 4 , insulating layer 3 and ground electrode 2 . Depend on figure 1 As shown in , there is a discharge gap 5 between each ground electrode 2 and the insulating layer 3 , and there is a discharge gap 6 between ea...

Embodiment 2

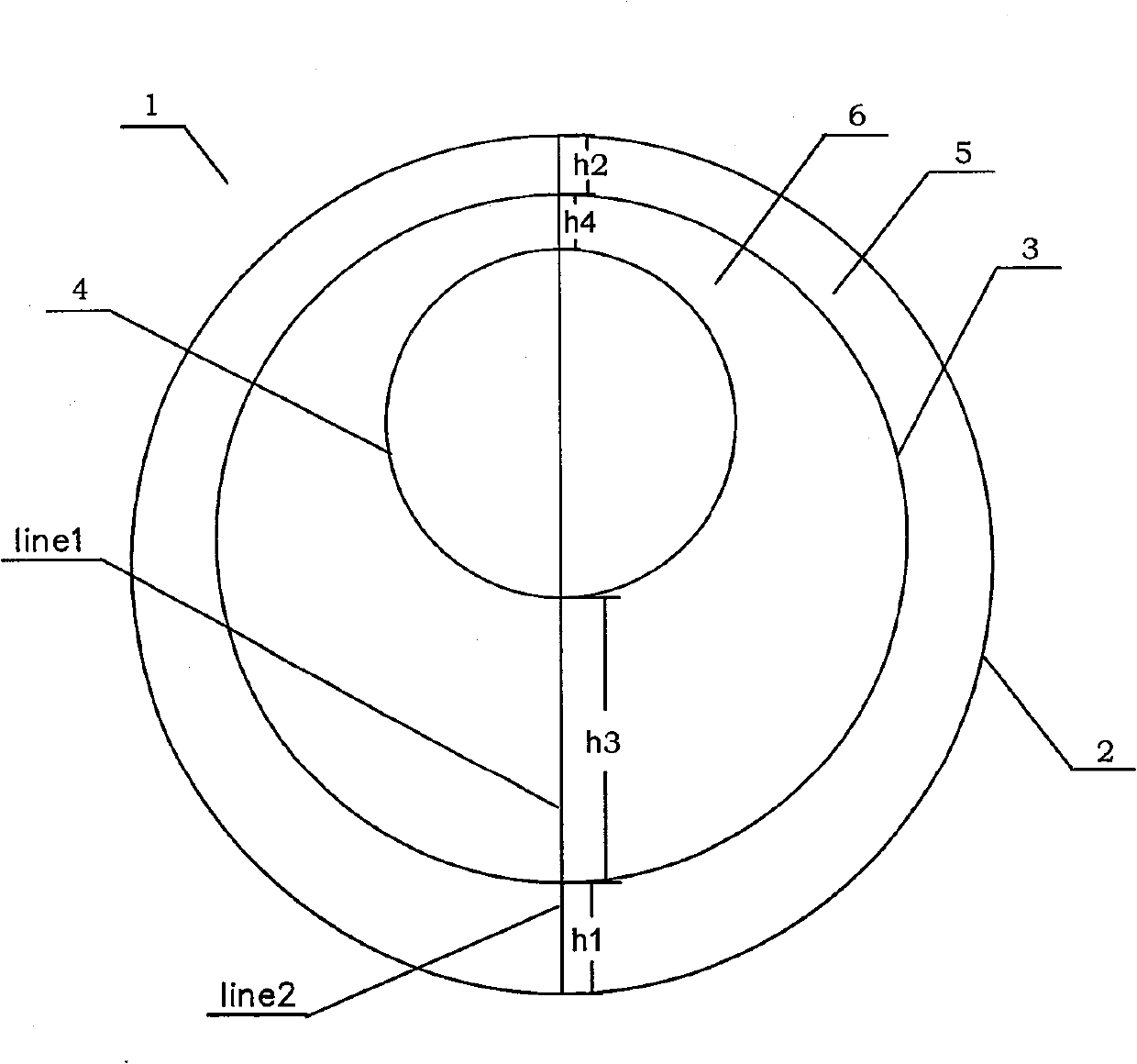

[0030] Such as figure 2 As shown, the discharge unit 1 for the ozone generator provided by Embodiment 2 of the present invention includes a ground electrode 2, an insulating layer 3 and a high-voltage electrode 4 installed in an annular phase, and the sequence from the inside to the outside is high-voltage Electrode 4, insulating layer 3 and ground electrode 2. There are gaps 5 and 6 respectively between the ground electrode 2 and the insulating layer 3 and between the high voltage electrode 4 and the insulating layer 3 . The gaps 5 and 6 in this discharge cell are uninterrupted, continuous and smooth and parallel to each other, and there is no air distribution element in the gap. The average value H2 of the gap 6 between the high voltage electrode 4 and the insulating layer 3 is 1-100 times the average value H1 of the gap 5 between the ground electrode and the insulating layer. Wherein, the average size H1=1 / 2(h1+h2) of the gap 5 between the ground electrode and the insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com