fuel pressure regulator

A pressure regulating device, fuel injection device technology, applied in the direction of fuel injection device, liquid fuel feeder, charging system, etc., can solve the problems of cost increase, easy bending, restriction, etc., and achieve the purpose of suppressing fuel pressure fluctuations and increasing design Degree of freedom, to achieve the effect of large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

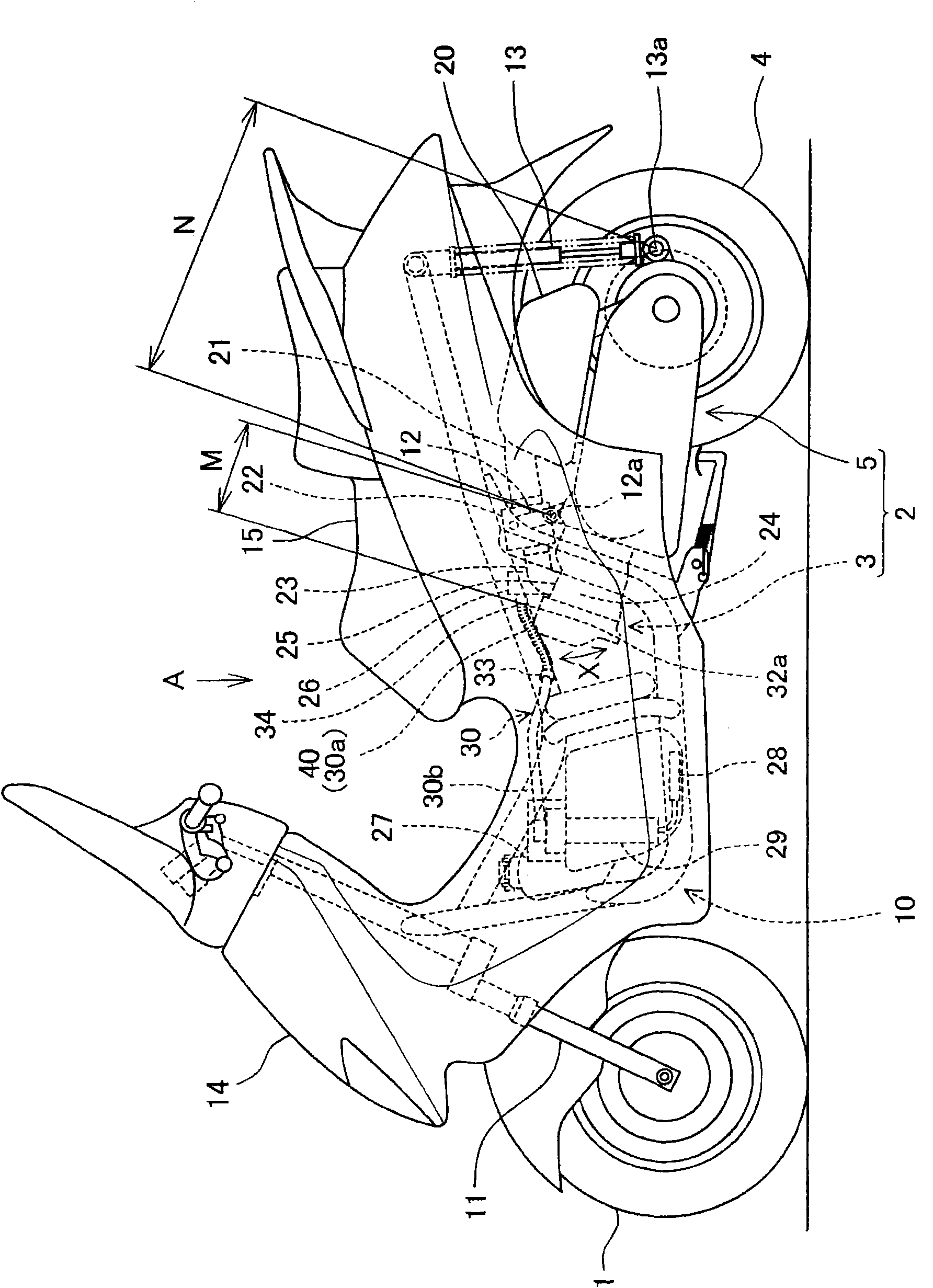

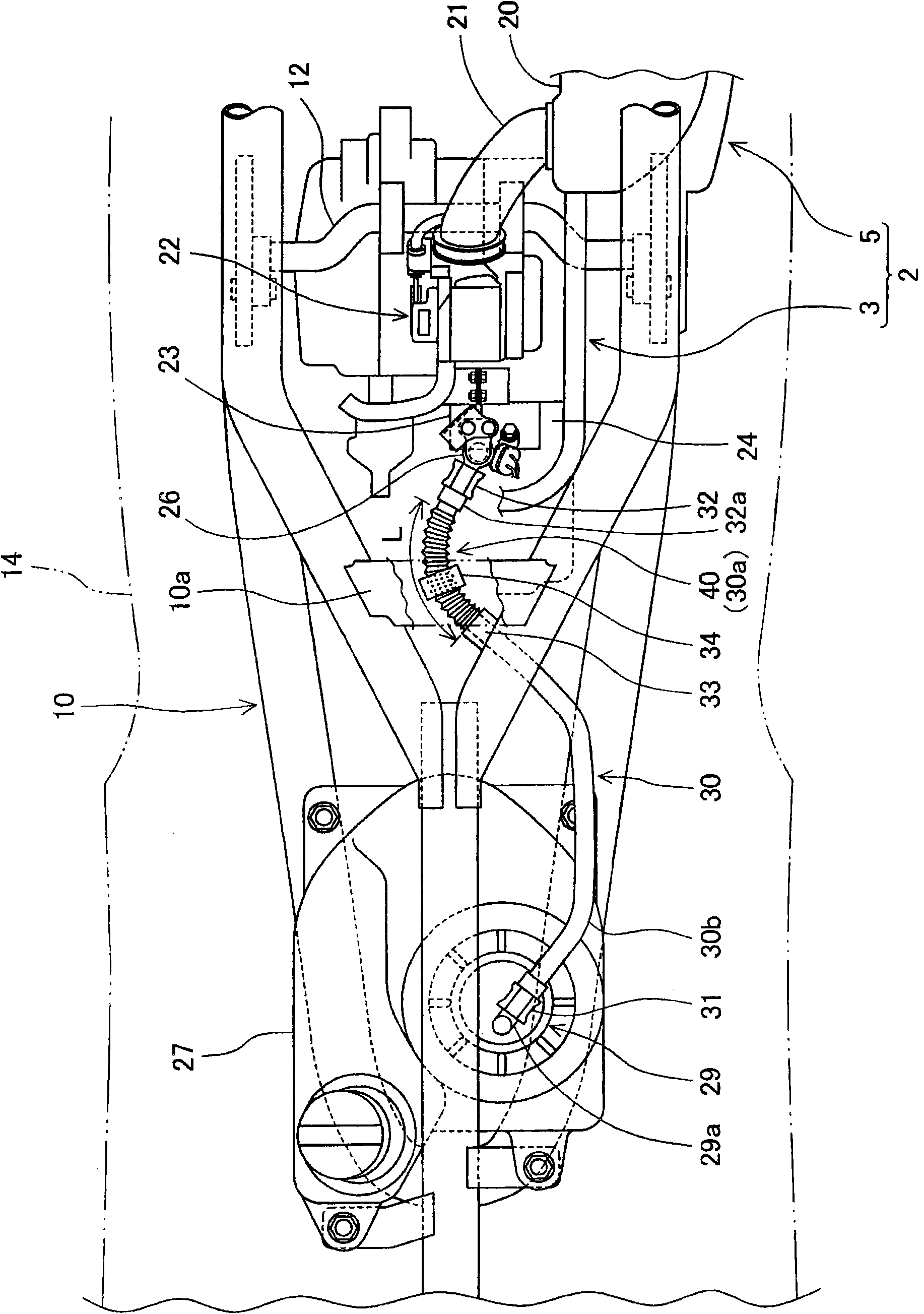

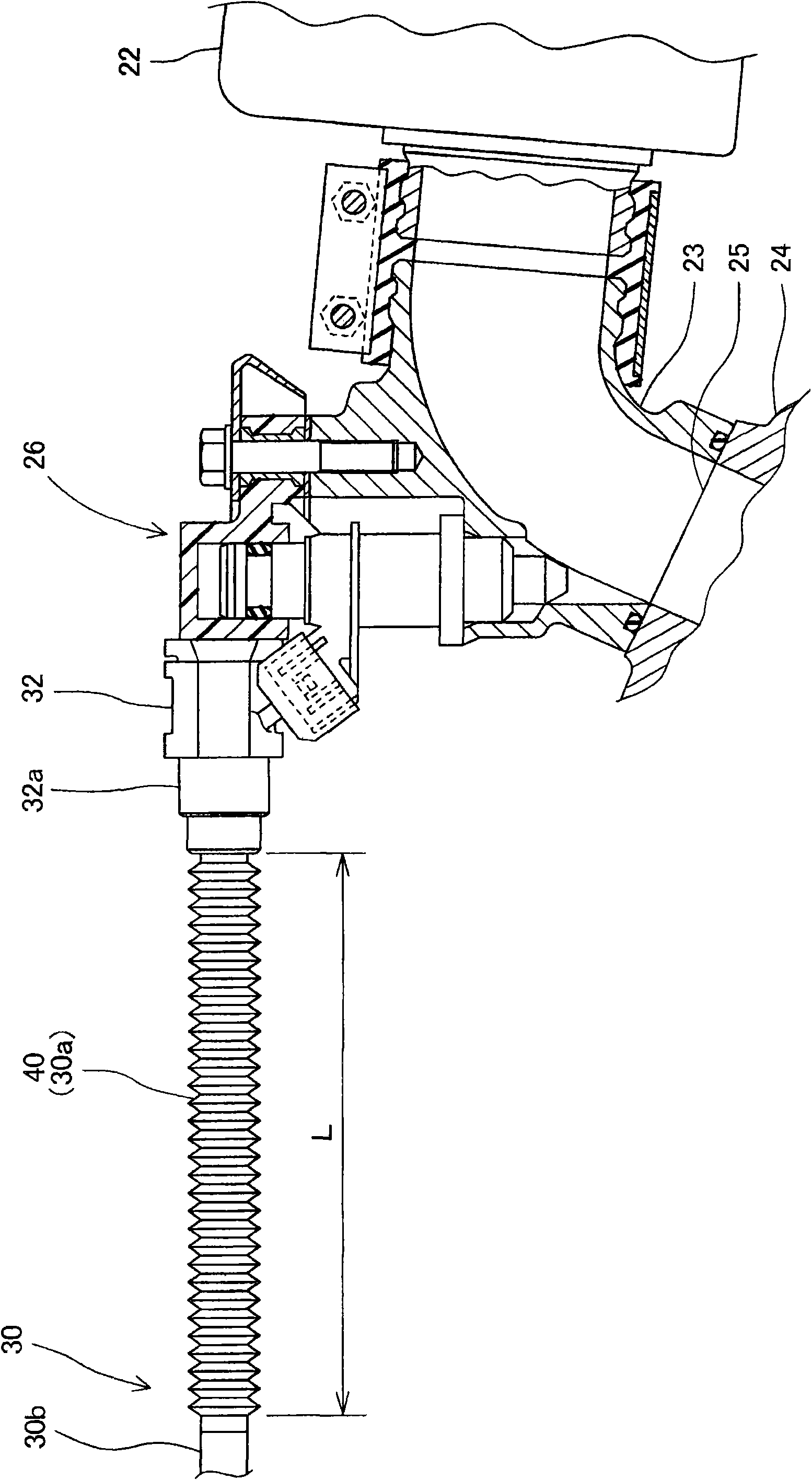

[0044] based on Figure 1 to Figure 6 The first embodiment of the present invention and its modifications will be described.

[0045] Such as figure 1 and figure 2 As shown, a front fork 11 is rotatably provided at the front end of a vehicle frame 10 of a small motorcycle, and a front wheel 1 is rotatably supported on a lower portion of the front fork 11. The bracket 12 supports the front part of the power unit 2 so as to be able to swing up and down.

[0046] The power unit 2 is composed of a single-cylinder engine (internal combustion engine) 3 and a continuously variable transmission 5, wherein the single-cylinder engine 3 is arranged at the front of the power unit 2 so that the axis of the cylinders is inclined forward and upward, and the continuously variable transmission 5 is used for rearward The wheel 4 transmits the output of the engine 3 after the continuously variable transmission. The rear wheel 4 is supported on the rear portion of the power unit 2 . A rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com