Heat supply progressively increasing type ignition heat-insulating furnace

A kind of ignition holding furnace, incremental technology, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve the problems of increasing operational complexity and safety hazards, increasing preheating equipment and costs, etc., to save consumption and simple structure Compact, burst-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

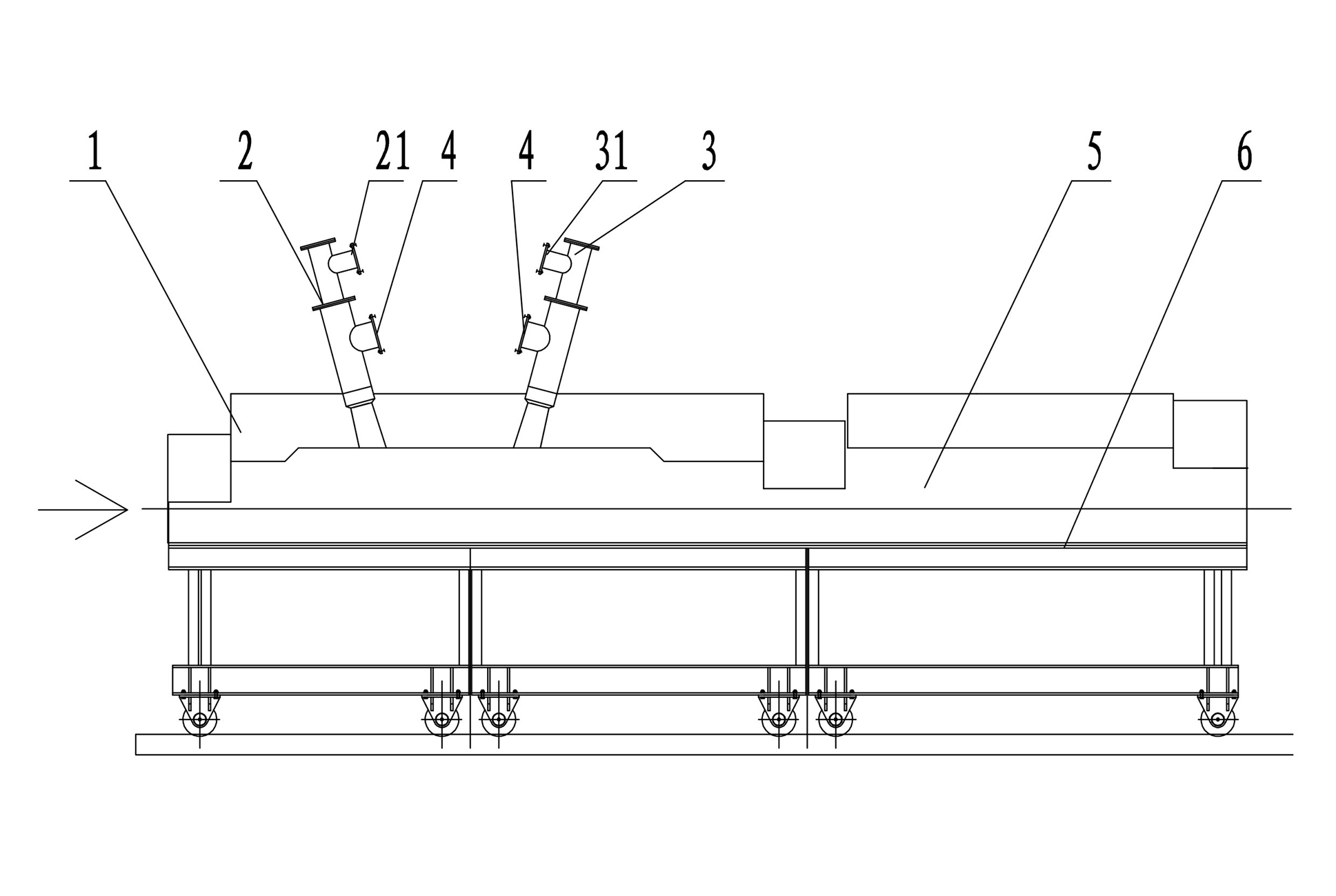

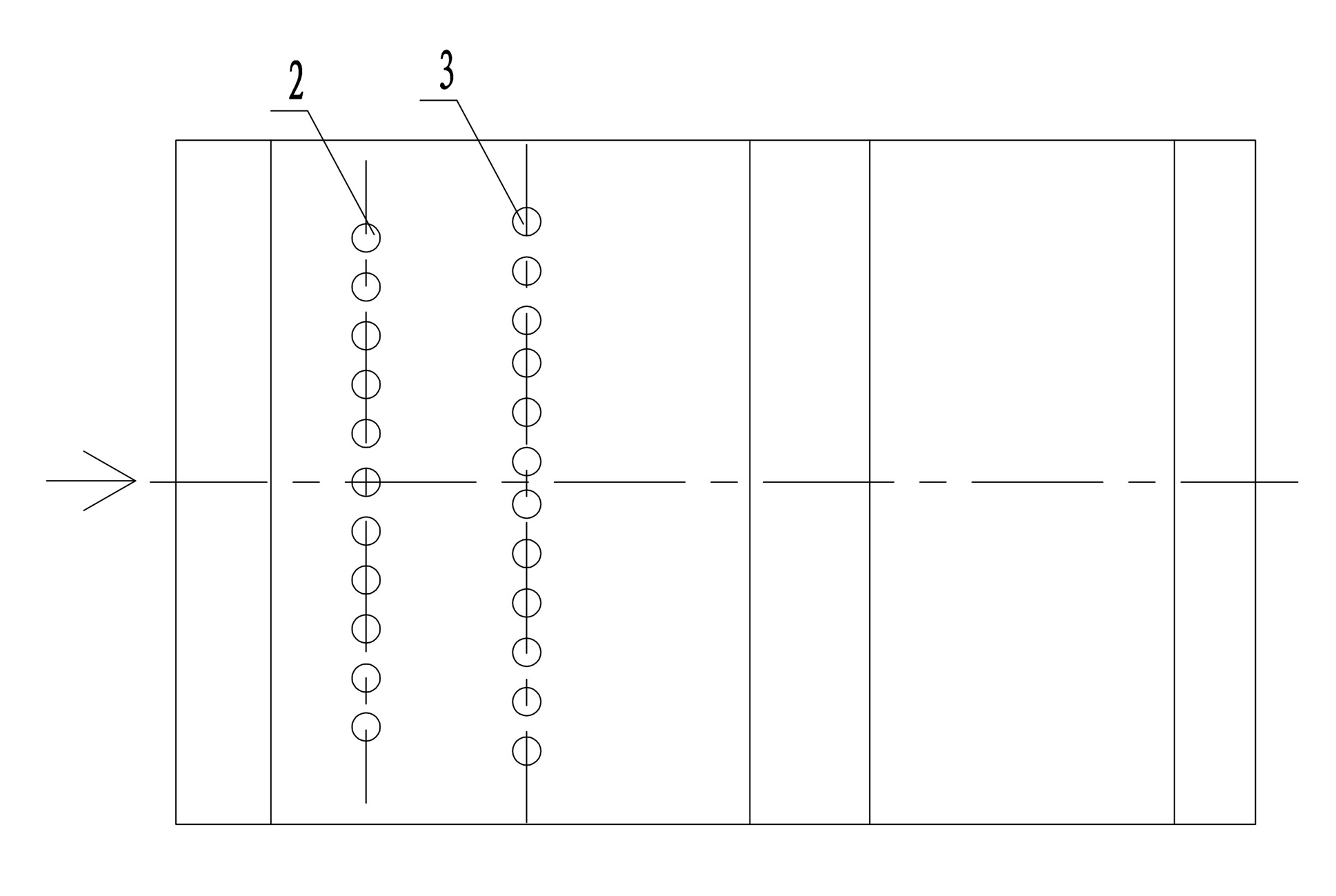

[0024] Embodiment 1: as figure 1 and figure 2 As shown, the heat supply incremental ignition holding furnace of the present invention includes a furnace body 1 and a burner assembly, the burner assembly is installed on the furnace body 1, and the burner assemblies include sequentially arranged The first row of burners 2 and the second row of burners 3, the calorific value of the fuel passed into the second row of burners 3 is higher than the calorific value of the fuel passed into the first row of burners 2. In this embodiment, both the first row of burners 2 and the second row of burners 3 are burners with a single fuel intake channel. The first row of burners 2 is provided with a low fuel value fuel passage 21 for feeding low fuel value fuel, and the second row of burners 3 is provided with a high fuel value fuel passage 31 for feeding high fuel value fuel. Both the first row of burners 2 and the second row of burners 3 are composed of a plurality of burners, and the plur...

Embodiment 2

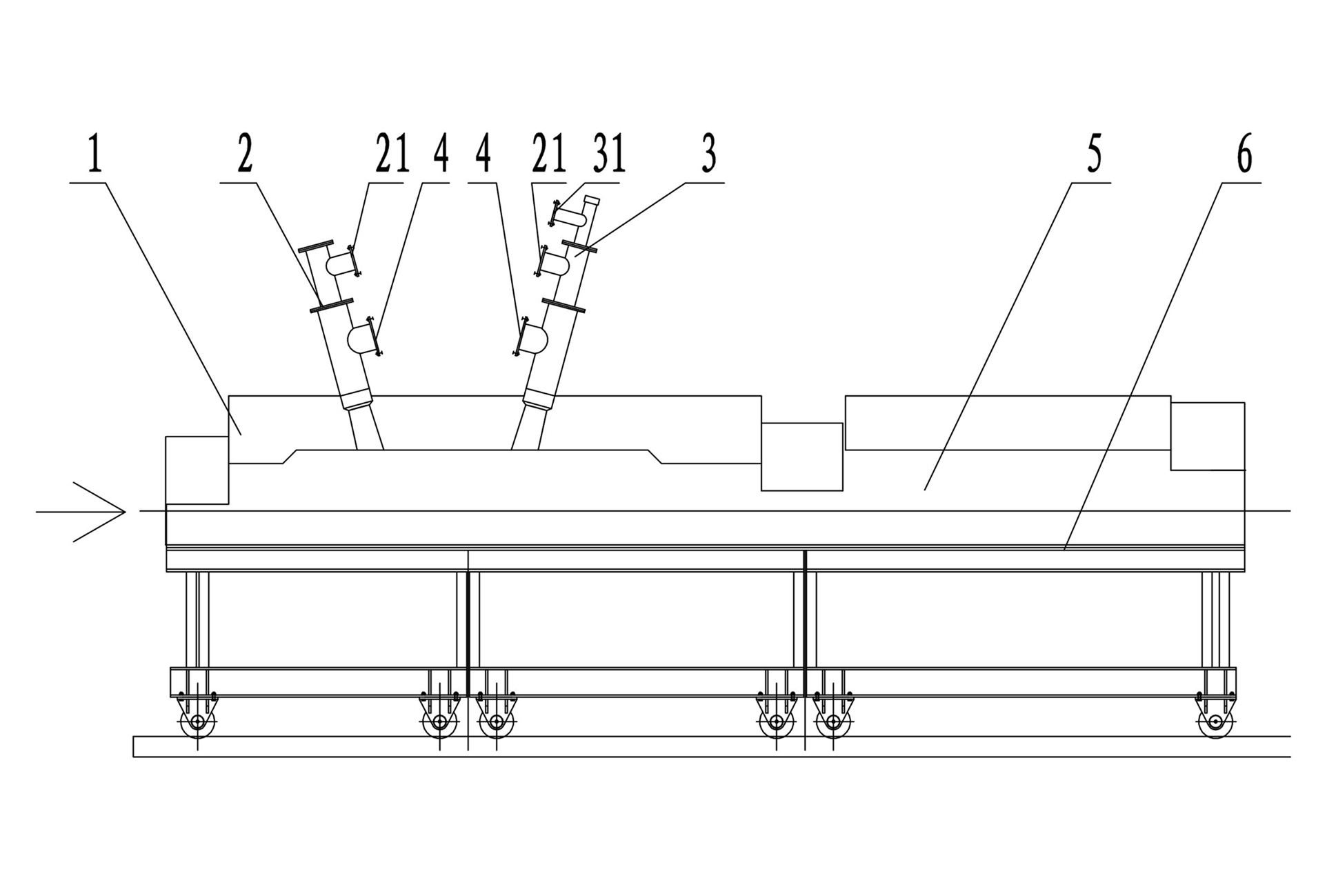

[0028] Embodiment 2: as image 3 and Figure 4 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the second row of burners 3 is a burner with more than two fuel intake passages, such as a three-way burner, which can simultaneously supply Three-way burner heating method with high calorific value and low calorific value fuels and proportional adjustment. Adjust the supply ratio of high calorific value and low calorific value fuels according to the actual heat needs. While ensuring the quality of sinter ore, it can save the consumption of high calorific value gas to the greatest extent. Its working principle is basically the same as that of Embodiment 1, so it will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com