Talbot effect-based aspheric surface detection system

A detection system and aspheric surface technology, which is applied in the field of optical testing, can solve the problems of affecting the detection accuracy, complicating the compensation mirror, and not being able to accurately obtain interference fringes, etc., and achieve good application prospects, high precision, and automatic detection and data processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The purpose and effects of the present invention will become more apparent by referring to the accompanying drawings in detail of the present invention.

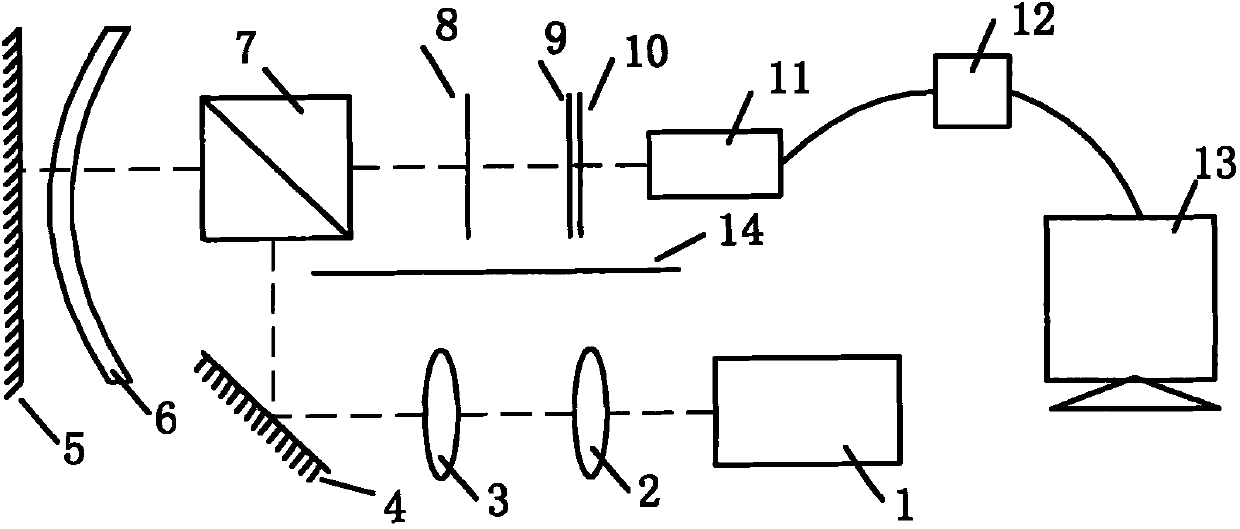

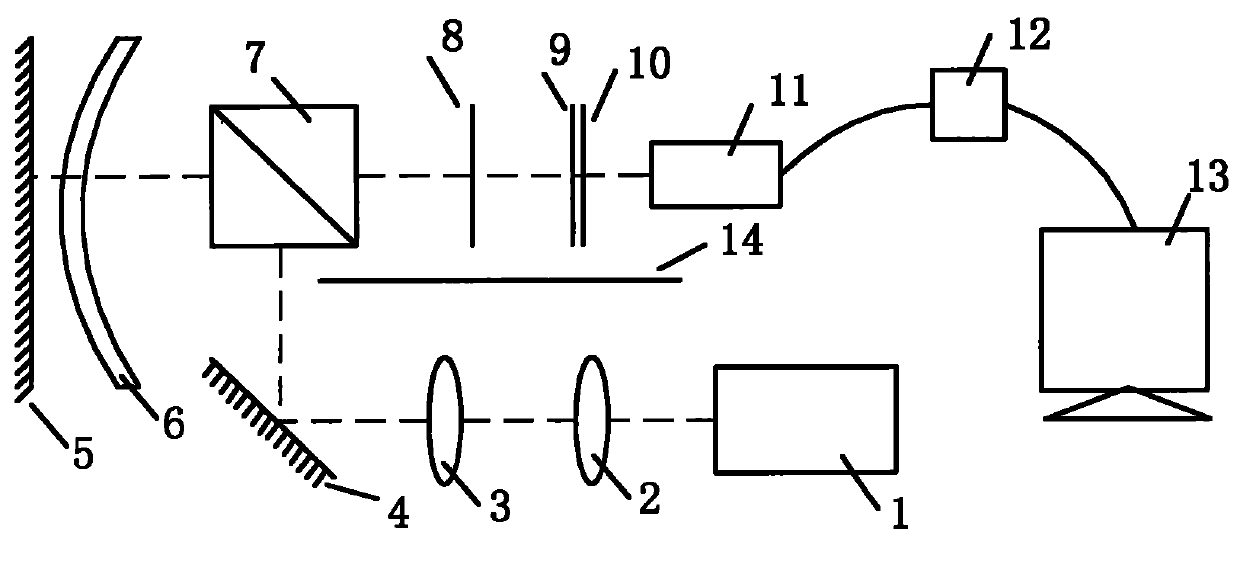

[0015] Such as figure 1 As shown, the aspheric surface detection system based on the Taber effect of the present invention includes a semiconductor laser 1, a microscopic objective lens 2, a collimating objective lens 3, a first reflector 4, a second reflector 5, an aspheric mirror to be tested 6, and a beam splitting prism 7 , the first grating 8, the second grating 9, the ground glass plate 10, the CCD camera 11, the image acquisition card 12, the computer 13 and the light baffle 14, the light beam that the semiconductor laser 1 sends is collimated and expanded by the microscopic objective lens 2 and the collimating objective lens 3 After the beam, it is irradiated to the first reflector 4, and the reflected beam of the first reflector 4 is divided into two beams by the dichroic prism 7, and the aspheric mirror 6 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com