Adaptation board, modifying method of double-station testing machine and testing method thereof

A testing machine and double-station technology, which is applied to measuring devices, components of electrical measuring instruments, and measuring electronics, can solve problems such as low testing efficiency, high testing cost, and long testing time, and achieve saving testing costs and saving the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

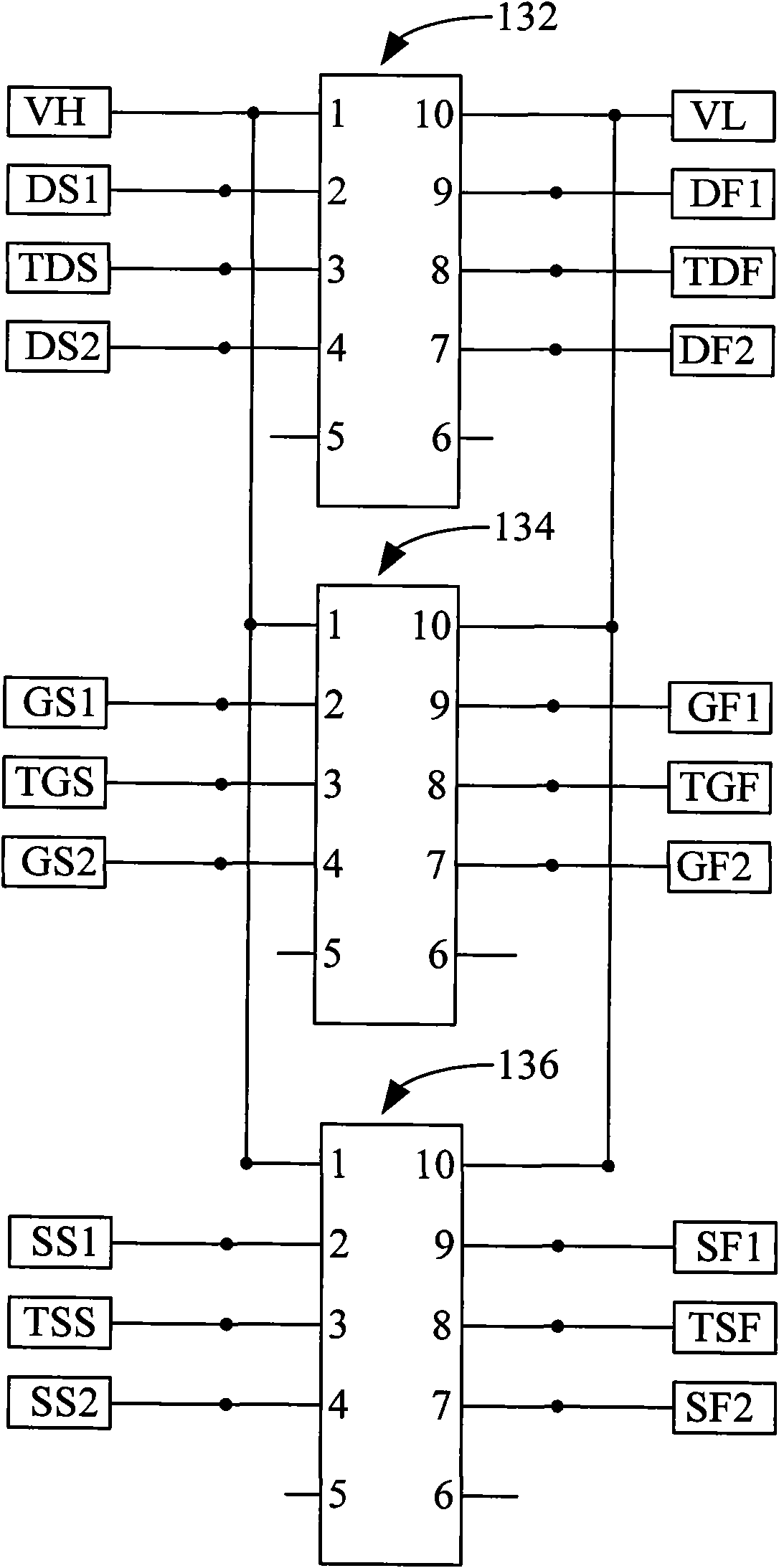

[0038] This embodiment provides an adapter board capable of refitting a single-station testing machine into a double-station testing machine. The adapter board includes: a honeycomb board, a socket for fixing the relay assembly on the honeycomb board, and connecting board; the adapter board is connected to the pins of the relay assembly, so that the common pin of the relay assembly is connected to the single-station testing machine, and the first signal pin of the relay assembly is connected to the first chip to be tested. The test terminal and the second signal pin of the relay assembly are connected to the test terminal of the second chip to be tested, the first chip to be tested is located at the first station, and the second chip to be tested is located at the second station. bit.

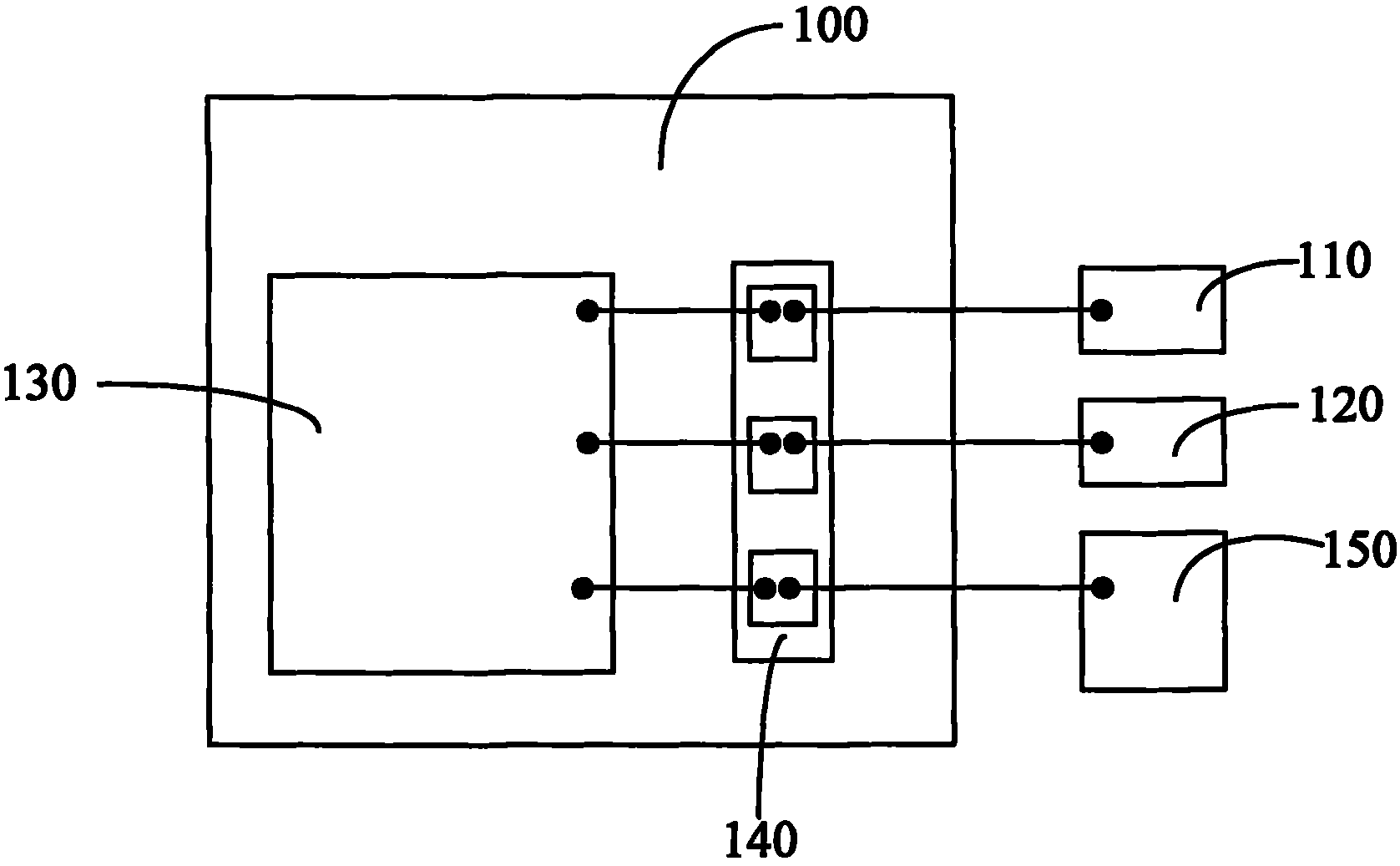

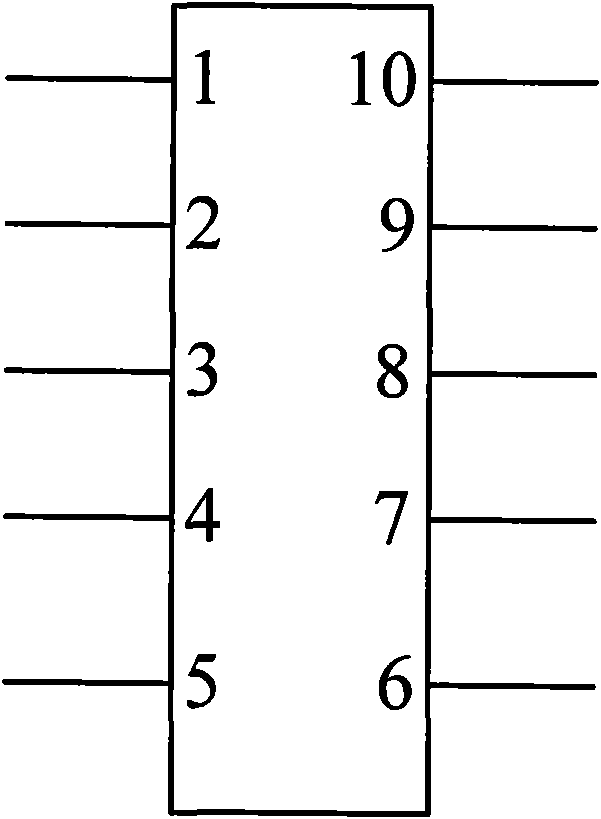

[0039] figure 1 It is a structural schematic diagram of the adapter plate of the present invention. Such as figure 1 As shown, the adapter board includes: a honeycomb board 100, a socket (no...

Embodiment 2

[0048] This embodiment provides a method for converting a single-station testing machine into a double-station testing machine, including:

[0049] First, determine a single-station testing machine with dual-station testing hardware resources;

[0050] The single-station testing machine in this embodiment can be a Kejin testing machine on the market, its model is MTWT103, and the supporting probe station of the Kejin testing machine can be a UF170 model MTWP024, and the matching probe card The model can be P0009-02-02-S0;

[0051] Secondly, the program of the single-station testing machine is reset through the relay assembly, so that the first chip to be tested is tested when the relay is powered on, and the second chip to be tested is tested when the relay is not powered;

[0052] Figure 4 For duplex test flow chart, such as Figure 4 As shown, the idea of resetting is: when the relay is not powered on, execute steps S11 and S12 in sequence, that is, test the first chip...

Embodiment 3

[0064] This embodiment provides a method for testing the chip under test by using the double-station testing machine described in Embodiment 2, including:

[0065] Firstly, placing the first chip to be tested and the second chip to be tested on the first station and the second station on the adapter board respectively;

[0066] Secondly, test the signal of the first chip under test and record;

[0067] Again, activate the second chip under test through a relay, test and record the signal of the second chip under test;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com