Light-emitting diode structure and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the quality of semiconductor structure crystals and reducing the antistatic ability of light-emitting diode devices, so as to increase the uniformity and brightness of light and ensure Uniformity, brightness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

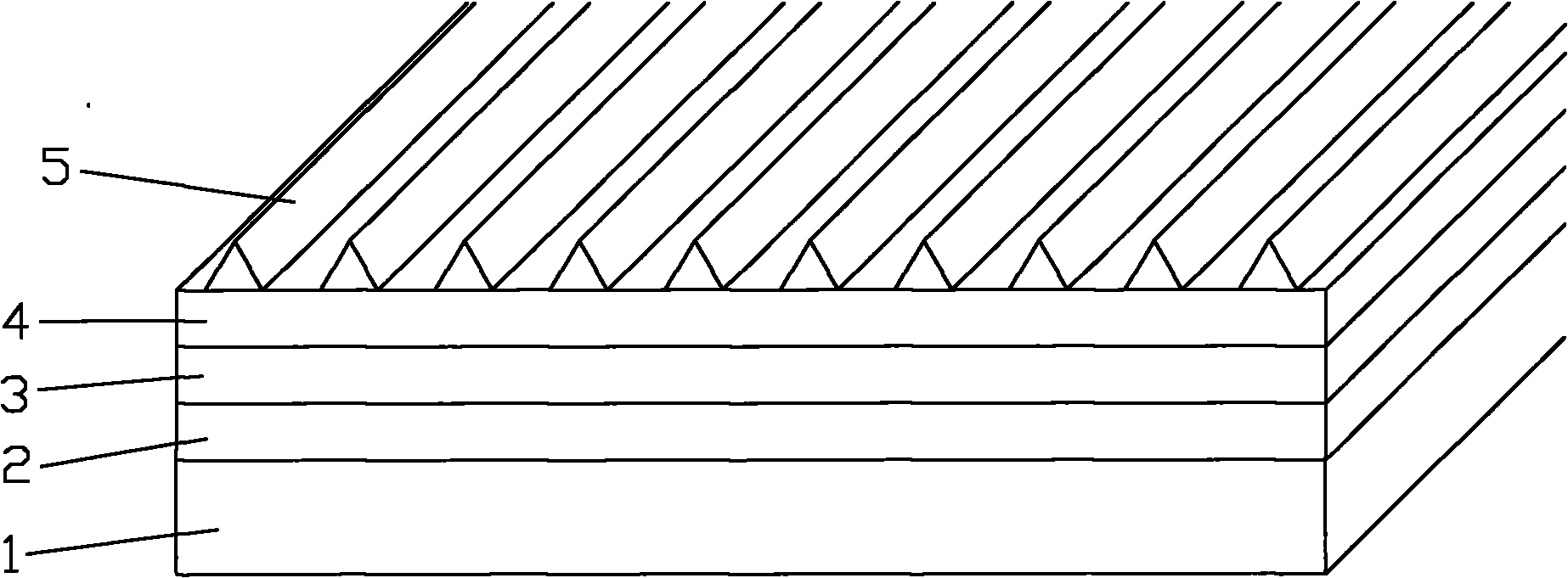

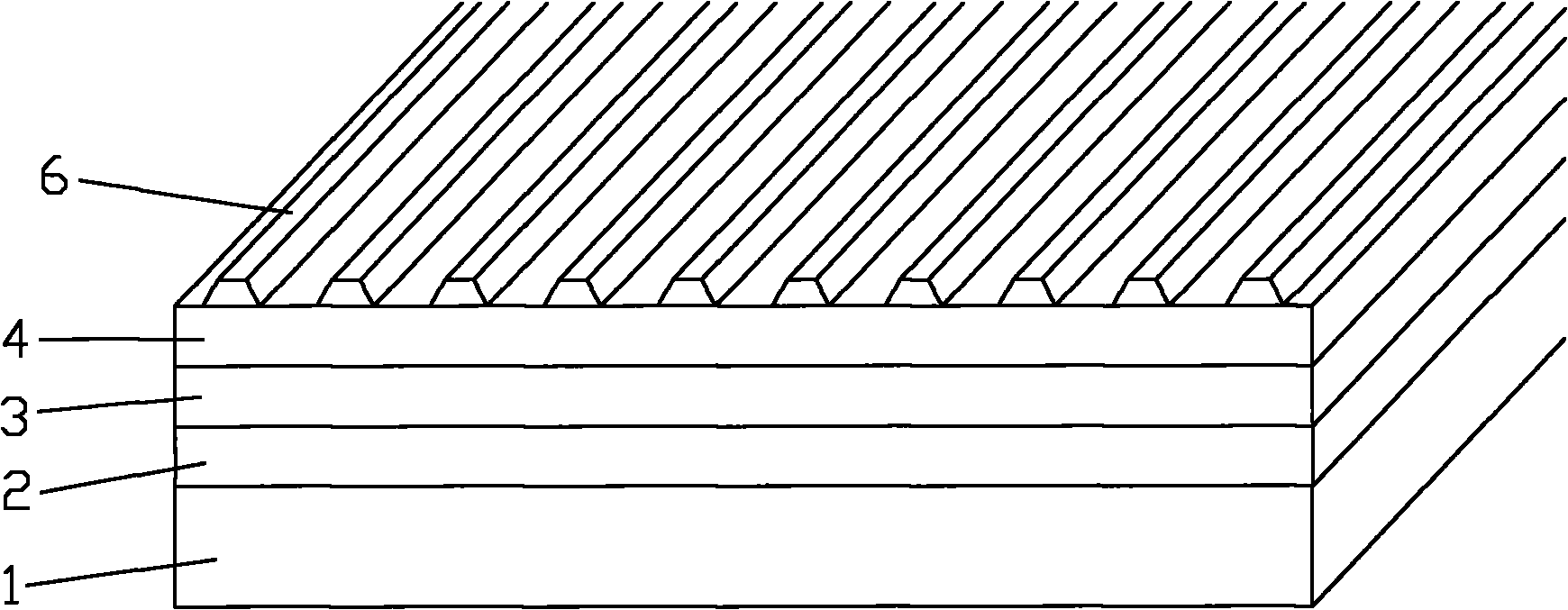

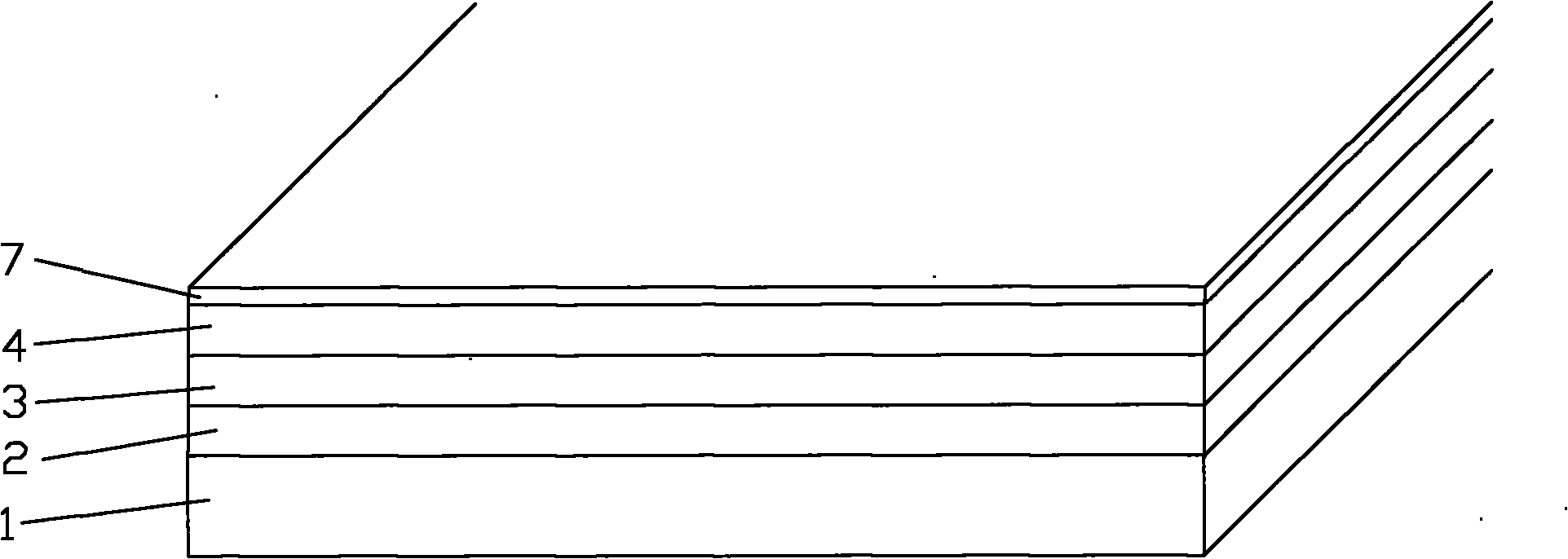

[0012] The invention discloses a light emitting diode structure, such as figure 1 with figure 2 As shown, it includes a substrate 1 and a light-emitting structure on the substrate. The light-emitting structure of the light-emitting diode includes an N-GaN layer 2, a multi-quantum well layer 3 and a P-GaN layer 4 from bottom to top. - On the GaN layer 4 there is a second epitaxial layer formed by secondary epitaxial growth, and the second epitaxial layer is a striped pyramid with a wide bottom and a narrow top.

[0013] The convex structure on the surface of the second epitaxial layer is a strip-shaped protrusion with a wide bottom and a narrow top, and the cross-section of the strip-shaped pyramid can be a triangle 5, such as figure 1 As shown, it can also be a trapezoid or a quadrilateral 6 close to a trapezoid, such as figure 2 As shown, for example, the upper and lower bases are not parallel, or the upper base is curved.

[0014] For the second epitaxial layer having a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com