Weft-catching device of air-jet loom for weaving chemical fiber filament yarn fabric

A filament fabric and air-jet loom technology, applied in looms, textiles, papermaking, textiles, etc., can solve problems affecting product quality, uneven color of cloth surface, etc., improve driving efficiency, wide application range, and convenient processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

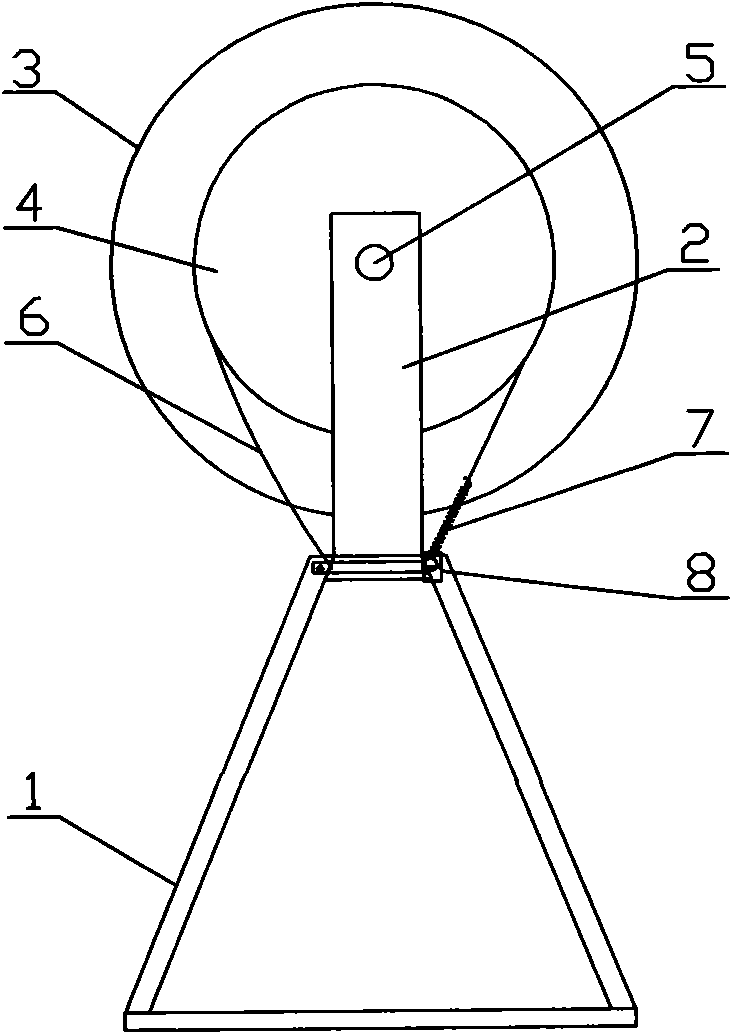

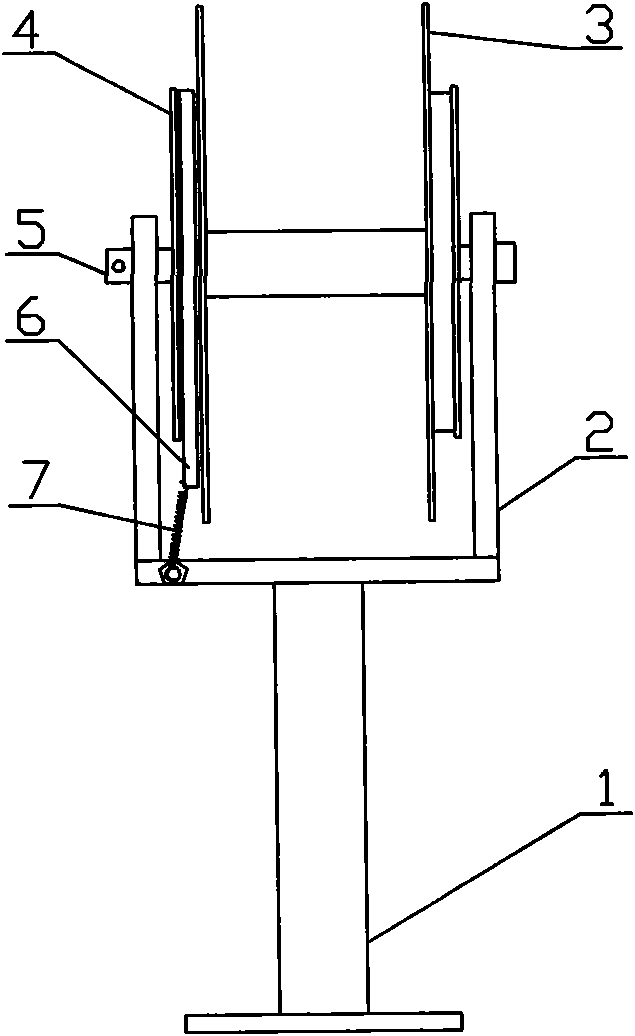

[0010] Depend on figure 1 , figure 2 It can be seen that the air-jet loom weaving chemical fiber filament fabric weft catching device of the present invention comprises an underframe 1, a fixed support 2 is located on the underframe 1, and one side of the hemmed bobbin 3 is provided with a belt pulley 4, and can also be provided on both sides. The belt pulley 4, the hemmed bobbin 3 is connected with the fixed bracket 2 through the fixed shaft 5, the friction belt 6 is placed in the groove of the belt pulley 4, and the round hole at one end of the friction belt 6 is connected with the bolt 8 on the bottom frame through the spring 7 , The round hole at the other end is directly connected with the bolt 8.

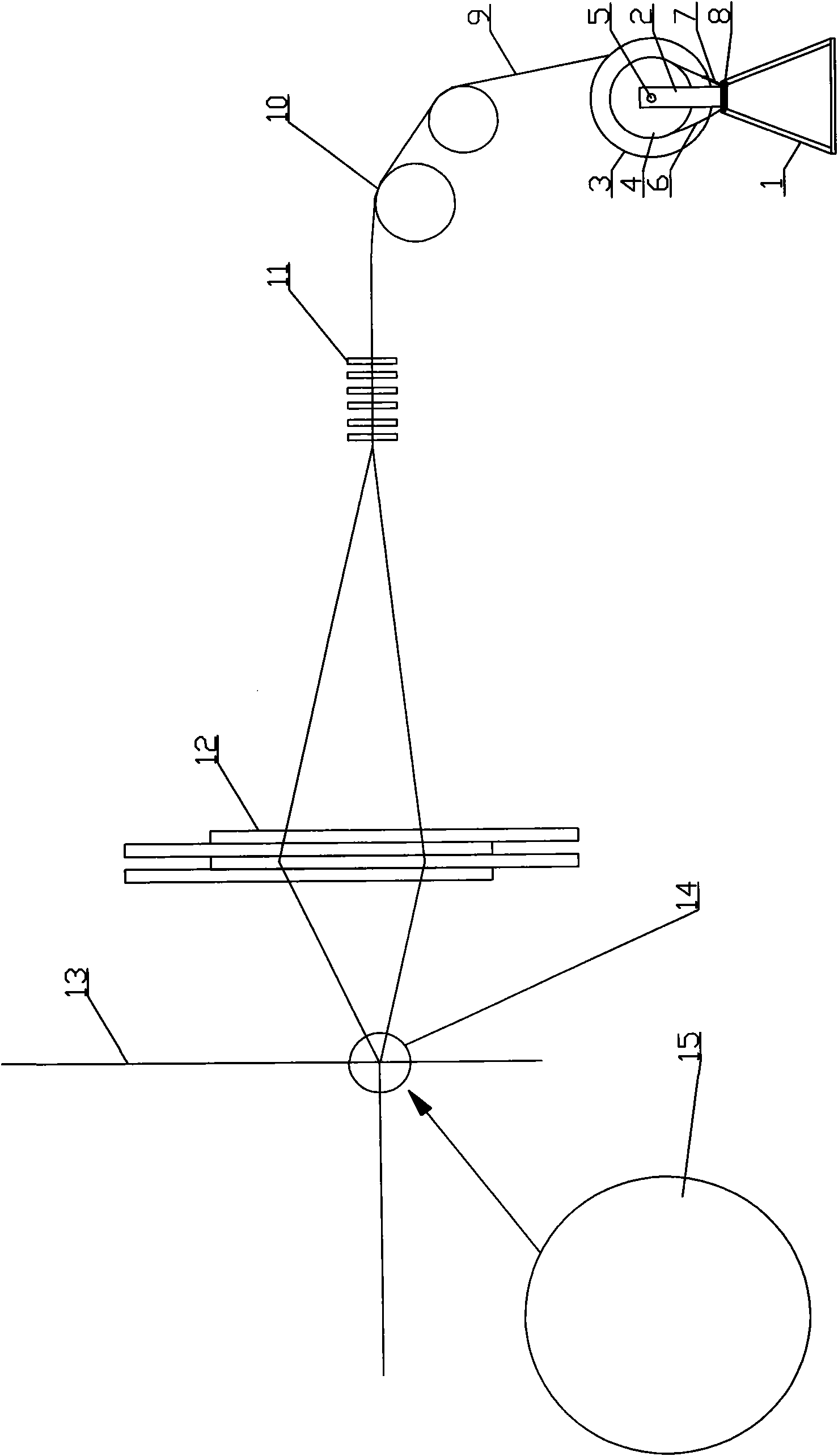

[0011] see image 3 , the air-jet loom weaving chemical fiber filament fabric weft catching device of the present invention is placed in the gap between the loom warp beam left disc and the loom wallboard, so that the normal circuit route will not be hindered in the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com