Biaxial multilayer cloth warp knitting machine

A biaxial, warp knitting machine technology, applied in flat warp knitting machines, warp knitting, textiles and papermaking, etc., can solve the problem of speeding up the working speed of cloth surface splitting needle parts, speeding up servo motors, and affecting the quality of finished cloth and other issues, to achieve the effect of easy modular control, quality assurance, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

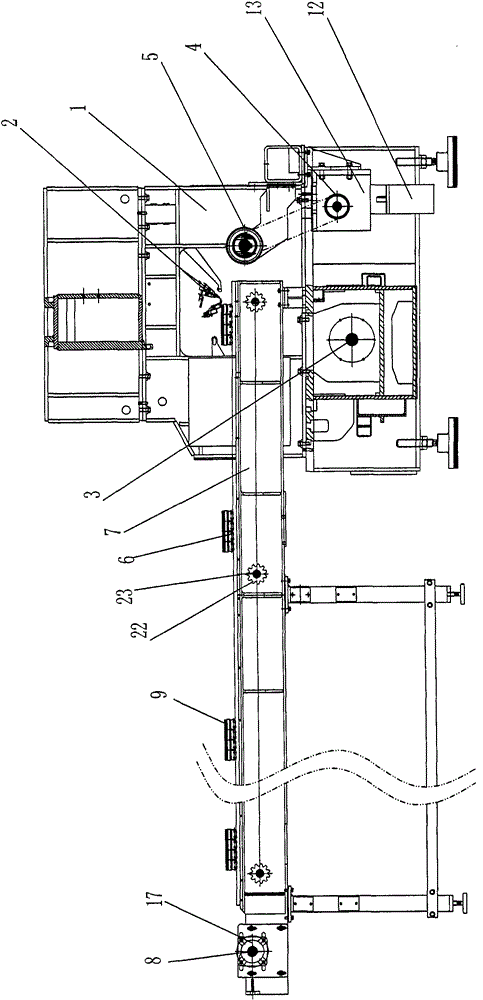

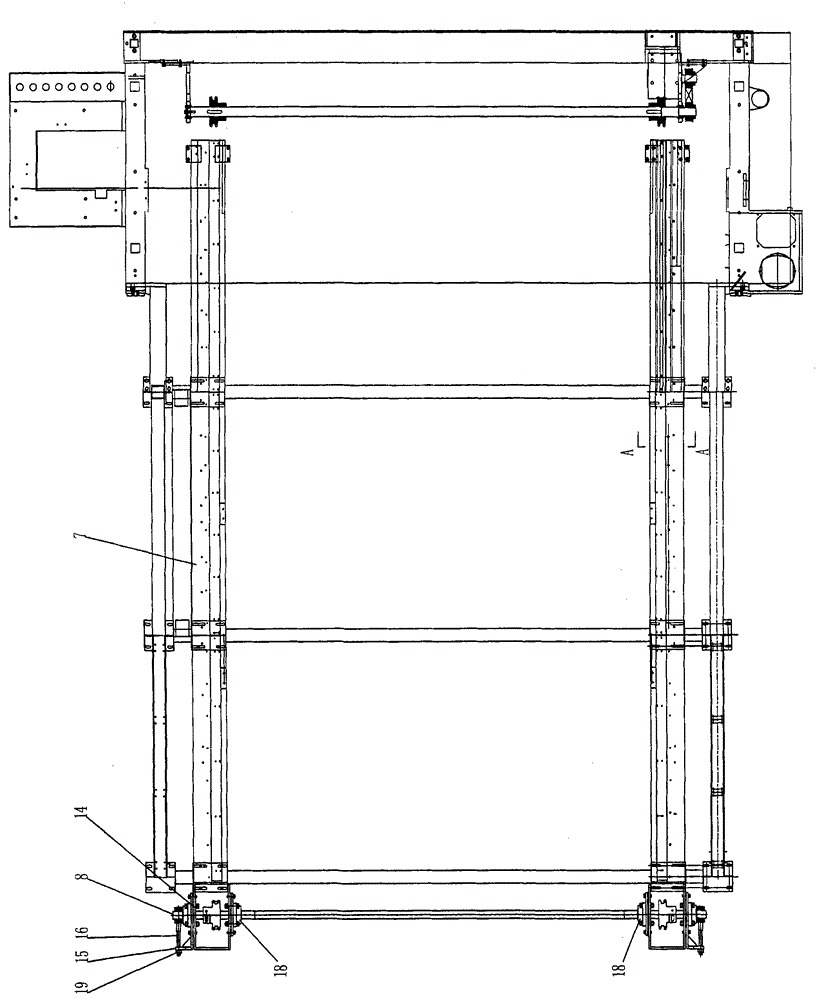

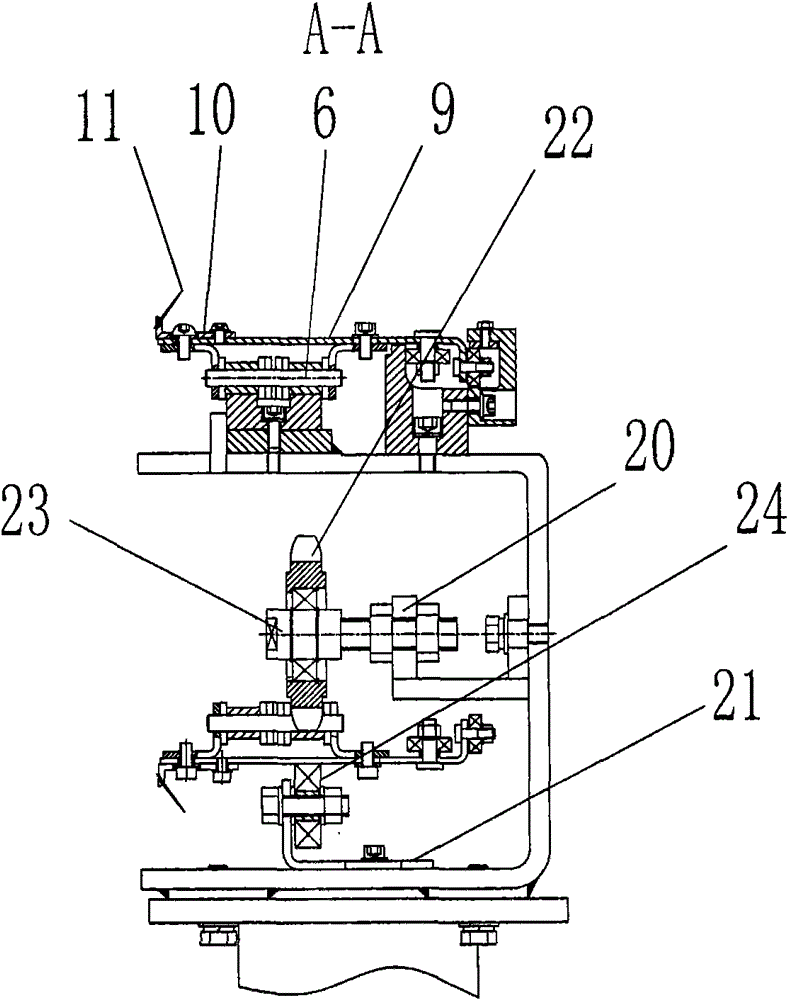

[0013] refer to Figure 1 to Figure 3 A kind of biaxial multi-layer cloth warp knitting machine shown, it comprises biaxial cloth face splitting needle part lathe bed 1, cloth face splitting needle part 2 and cloth face conveying device, described biaxial cloth face The bed of the surface dividing needle part 1 is provided with a biaxial machine head bed main shaft 3 for controlling the work of the surface dividing needle part 2, and the cloth surface conveying device includes a driving device and a speed reducer for sprocket pulling Synchronous pulley 4, rotary sprocket 5, double-row chain 6 for sprocket pulling and chain box 7, reducer for sprocket pulling synchronous pulley 4 is connected to rotary sprocket 5 through a synchronous belt, and rotary sprocket 5 is set On the tail sprocket pulling shaft 8 on the left and right sides of the chain box body 7, the double row chain 6 for sprocket pulling is arranged on the rotary sprocket 5, and the outside of the double row chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com