Anti-leakage treatment method and anti-leakage device at conjunction of pipeline and well wall

A treatment method and anti-leakage technology, applied in the direction of pipes/pipe joints/fittings, pipes, branch pipelines, etc., can solve the problems of difficulty in ensuring tightness, increase construction costs, and high rework costs, so as to improve construction efficiency, The effect of saving construction costs and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

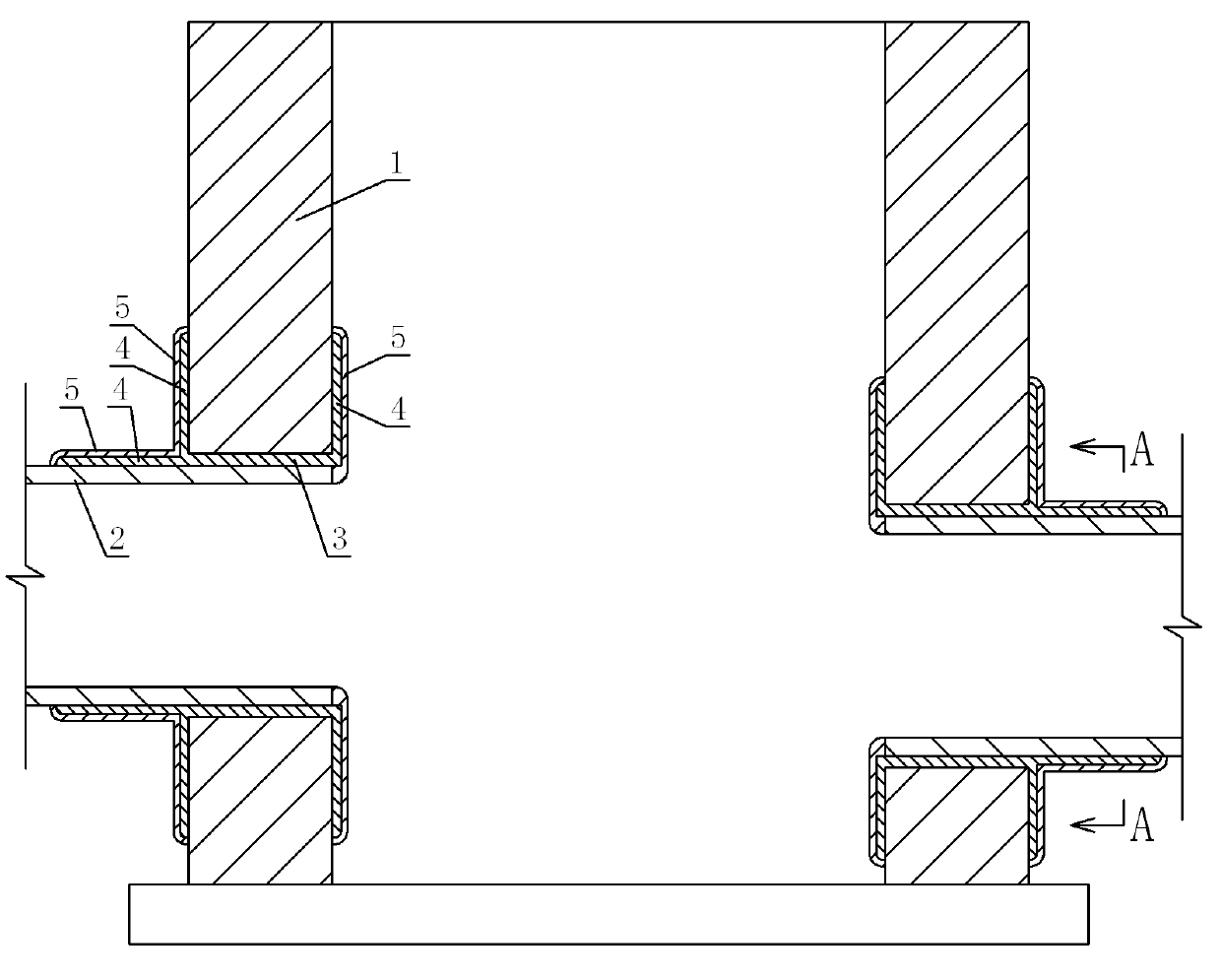

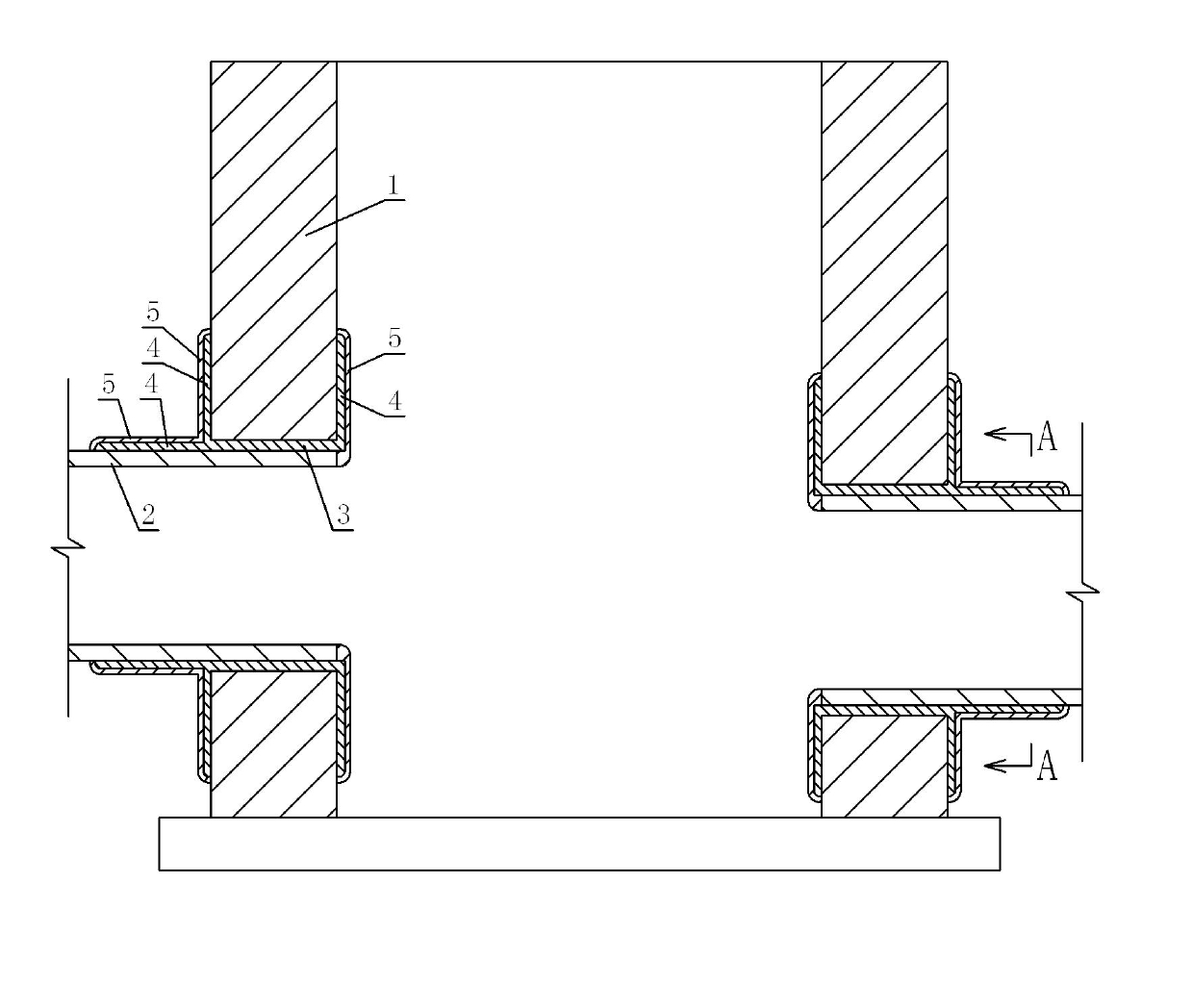

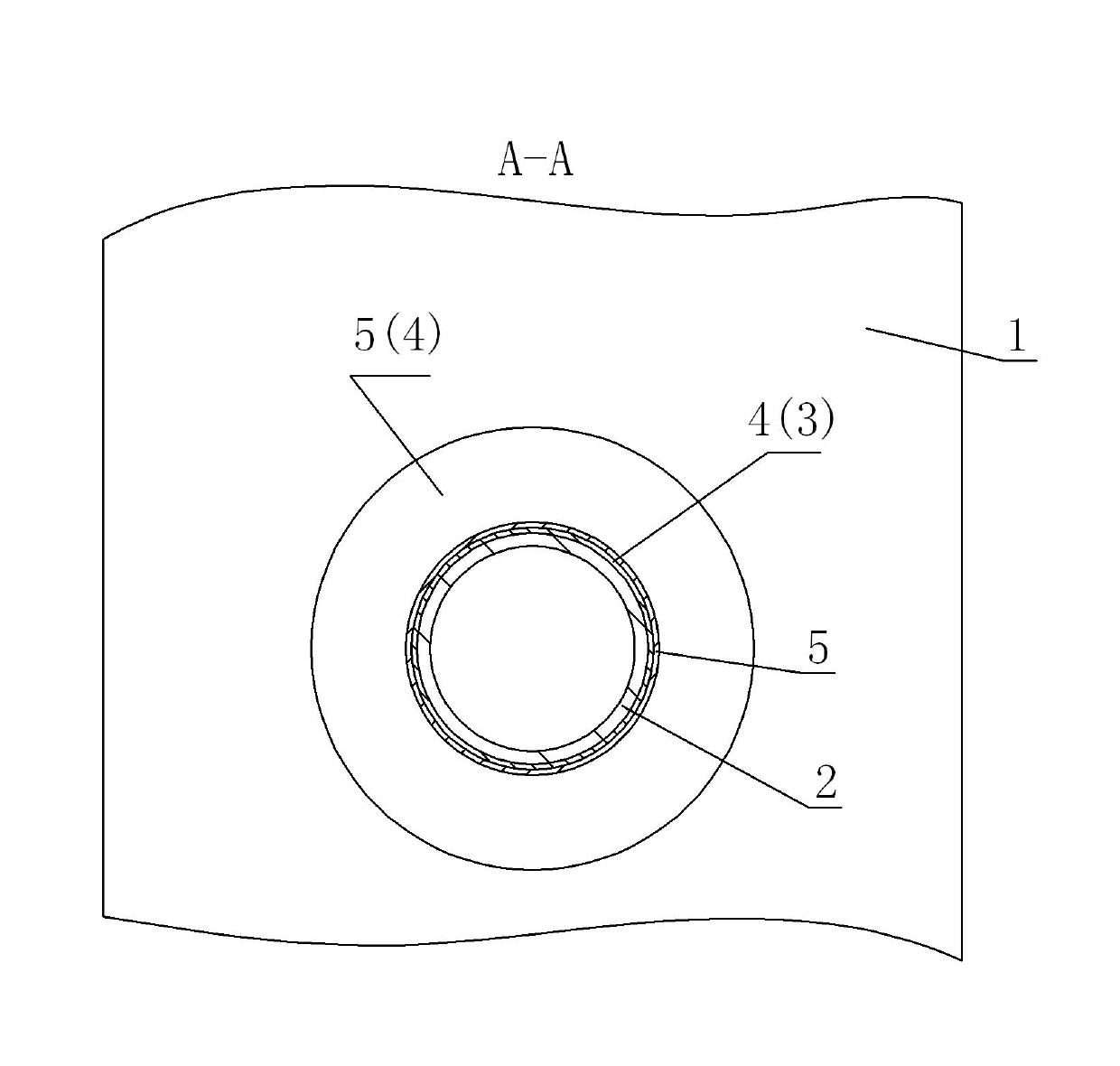

[0017] Such as figure 1 and 2 As shown, the present invention provides an anti-leakage treatment method for the connection between the pipeline and the well wall, which is characterized in that: after the pipeline 2 is installed on the well wall 1, the asphalt is first used to treat the gap between the pipeline 2 and the well wall 1. Fill the installation gap to make the asphalt fill the installation gap between the pipeline 2 and the well wall 1; then brush asphalt around the connection between the pipeline 2 and the well wall 1, so that the pipeline 2, the well wall 1, and the well wall 1 are filled in the installation gap. The asphalt joint layer 3 in the gap and brushing around the joint between the pipeline 2 and the well wall 1 (including the outer wall of the pipeline 2 and the well wall 1 outside the joint between the pipeline 2 and the well wall 1, and the 2 and the inner wall surface of the well wall 1 at the joint of the well wall 1) the asphalt smear layer 4 is co...

specific Embodiment approach 2

[0020] Such as figure 1 and 2 As shown, the present invention provides an anti-leakage device at the joint between the pipeline and the well wall. 2 and the asphalt smear layer 4 around the junction of the well wall 1 and the mortar smear layer 5 covering the outside of the asphalt smear layer 4, the pipeline 2, the well wall 1, the asphalt joint layer 3 and the asphalt smear layer 4 are connected as a whole.

[0021] (3) Examples

[0022] In the municipal road project of the Garden Expo Park, the method of the present invention is used to treat the connection between the pipeline and the inspection well. The specific method is as follows:

[0023] First build the inspection well wall 1 to the inner bottom elevation of the pipeline 2, then install the pipeline 2, and then build a brick arch on the upper part of the pipeline 2 after the installation is completed. After the pipeline 2 is installed and the brick arch masonry is completed, asphalt is used to fill the joints, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com