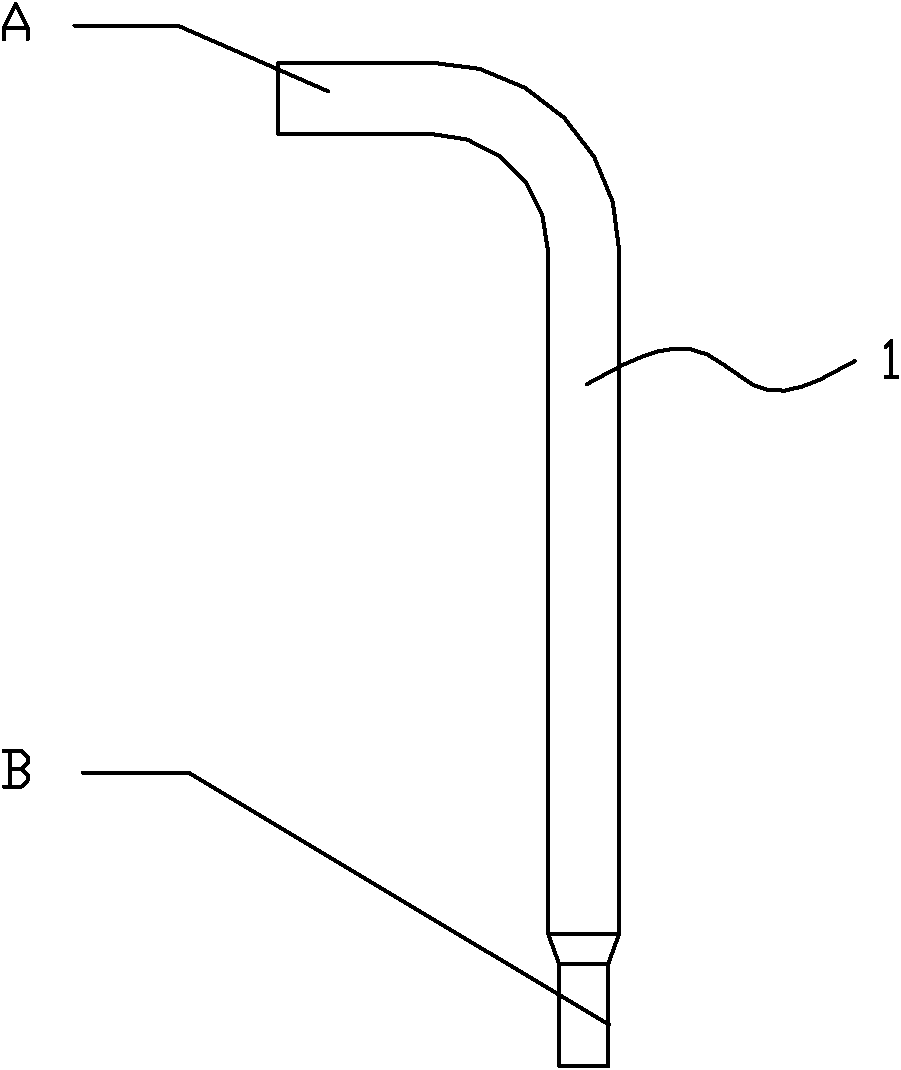

Sound-proof transition pipe

A technology of transition pipe and pipe diameter, which is applied in the direction of fluid circulation arrangements, refrigeration components, refrigerators, etc., can solve the problems of fluorine flow noise and other noises, and does not eliminate the noise reduction function of refrigerant fluorine flow noise, etc. The effect of low frequency noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

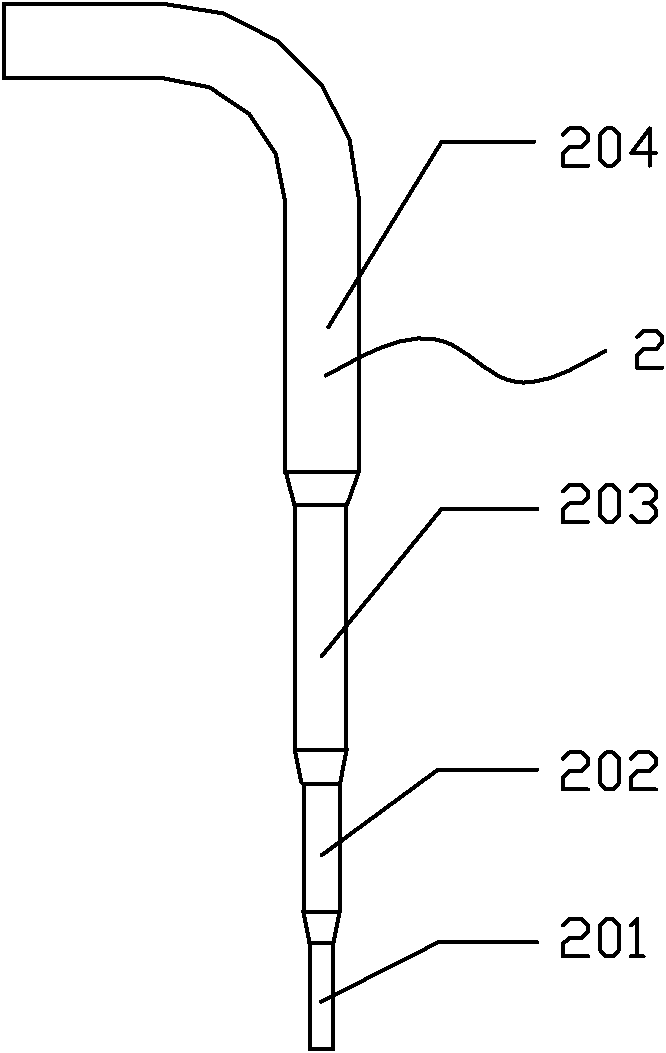

[0018] The muffler transition pipe 2 of the present invention adopts multi-stage depressurization. During the flow process of the refrigerant, the pressure gradually decreases step by step, avoiding a rapid pressure drop, no sharp turbulent flow phenomenon, and no rapid cavitation that causes the bubbles to explode violently. Breaking, so that there will be no whistling and other noises of fluorine flow, improve sound quality and reduce noise by 2-3dBA. According to the pipe diameter of the capillary tube and the heat exchanger copper tube in the present invention, more than two pressure drop levels can be set between the two. This embodiment adopts a three-level pressure drop method, and the following uses three levels The muffler transition pipe for pressure drop will be described in detail. In this paper, unless otherwise specified, the pipe diameter unit is mm.

[0019] Such as figure 2 As shown, when the diameter of the capillary tube is φ3 and the diameter of the coppe...

Embodiment 2

[0021] According to the diameter of the capillary tube and the heat exchanger copper tube, two pressure drop levels are set between the muffler transition tube in this embodiment. When the diameter of the copper pipe is φ7, the transition pipe 2 is provided with a secondary pressure drop, which is realized by three sections of pipe sections with different pipe diameters, among which the pipe diameter of the connecting pipe 201 with the capillary is φ5.5, and the primary pressure drop pipe section 202 is The pipe diameter is φ6, and the secondary step-down pipe section 203 is φ7.

Embodiment 3

[0023] This embodiment adopts a four-stage pressure drop method: when the diameter of the shunt capillary used is φ2.7 and the diameter of the copper tube of the heat exchanger is φ9.52, the transition pipe 2 is provided with four-stage pressure drop, which is divided into five sections. The pipe section of the pipe diameter is realized, wherein the pipe diameter of the connecting pipe 201 with the capillary is φ3.5, the pipe diameter of the first-stage depressurization pipe section 202 is φ4.5, the second-stage depressurization pipe section 203 is φ6, and the third-stage depressurization pipe section 204 is φ7.5, φ9.52 for the four-stage step-down pipe section.

[0024] Certainly, there are other combinations, which also belong to the scope of the present invention. Usually, the inner diameter of the connecting pipe 201 of the capillary is 0.5-1mm larger than the diameter of the capillary. In order to ensure that one end of the capillary is inserted into the pipe section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com