Device and method for driving and controlling stepper motor

A stepper motor and motor control technology, applied in the direction of motor generator control, control system, electrical components, etc., can solve the problems of increasing system price and system complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

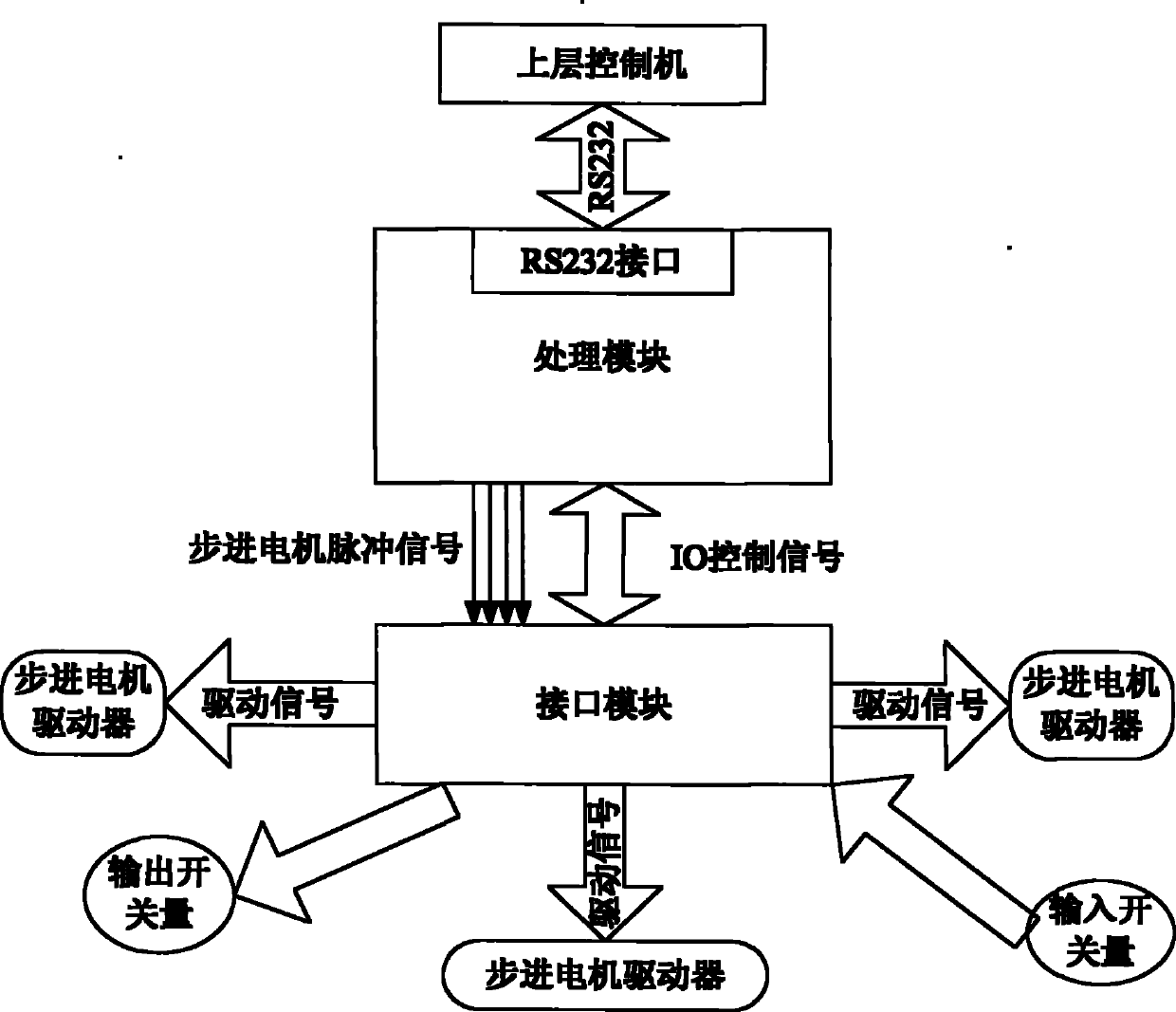

[0066] Embodiment 1, a drive control device for a stepper motor, such as figure 2 shown, including:

[0067] The upper layer control machine is used to generate motor control commands and set configuration data;

[0068] The processing module is used to receive the motor control command and configuration data, and when the motor control command instructs to drive the motor, output a stepper motor pulse signal according to the configuration data to complete the motor control.

[0069] The interface module, in which the peripheral switching value and motor drive circuit for specific applications is built, is connected with the peripheral equipment, and is used to output the driving signal to the external stepping motor driver according to the pulse signal of the stepping motor to complete the stepping motor. drive control.

[0070] The upper layer control machine can also be further used to generate an IO operation command; the IO operation command includes: IO multiplexing e...

Embodiment 2

[0155] Embodiment 2, a driving control method of a stepping motor, comprising:

[0156] Generate motor control commands, set configuration data;

[0157] When the motor control command indicates to drive the motor, output a stepper motor pulse signal according to the configuration data;

[0158] Outputting a driving signal to an external stepping motor driver according to the pulse signal of the stepping motor to complete the driving control of the stepping motor.

[0159] The method may further include generating an IO operation command; performing IO channel input upload and output control, reading and writing configuration data, and switching control etc. according to the IO operation command; the IO operation command includes: IO multiplexing enable , Interrupt enable.

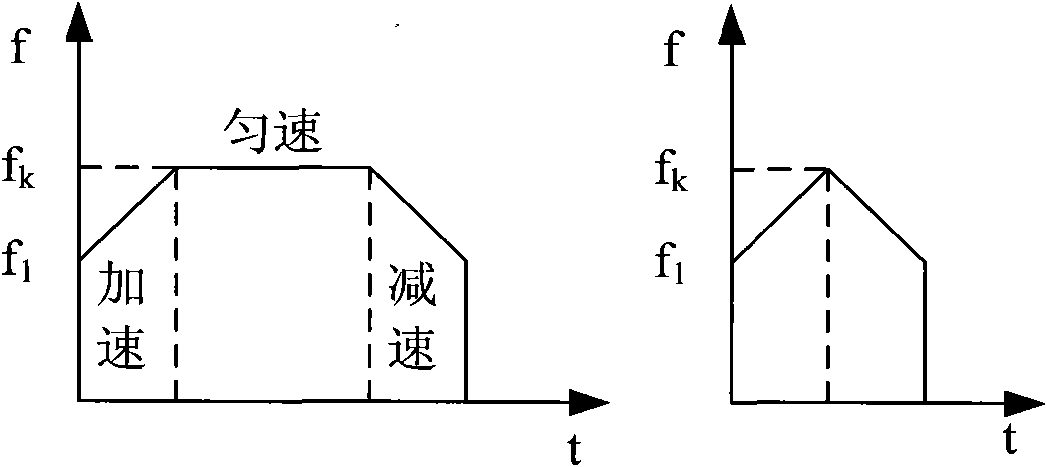

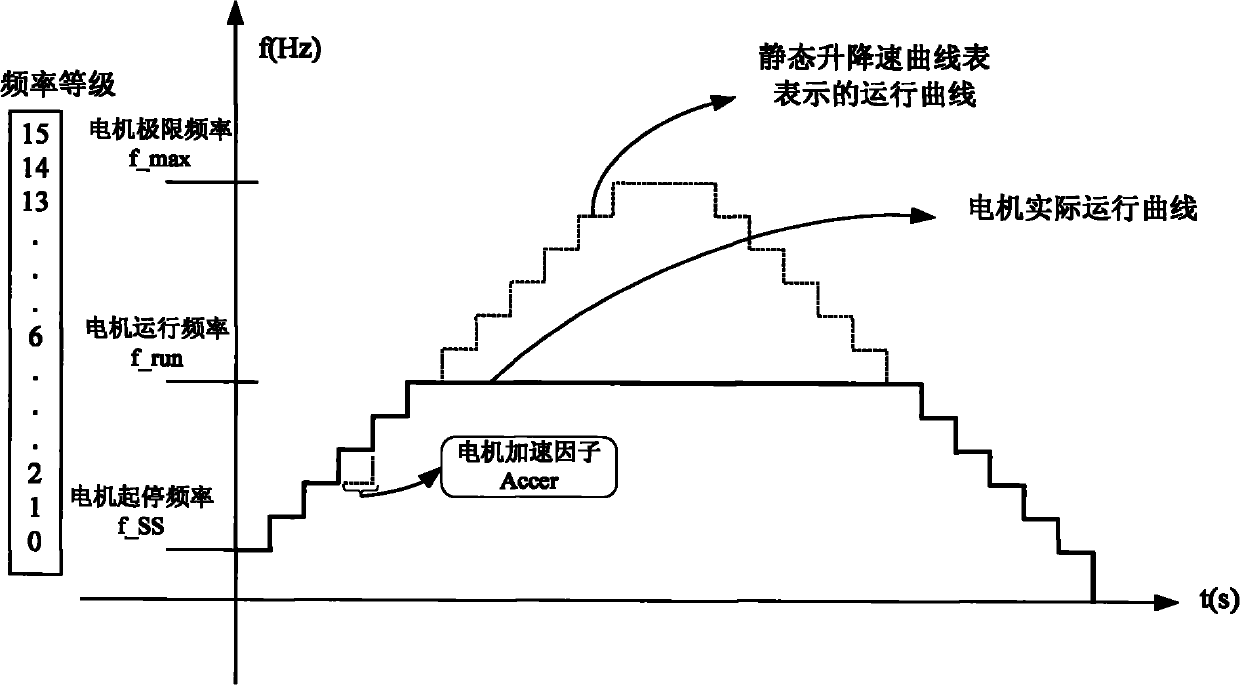

[0160] In this embodiment, several (possibly but not limited to 16) frequency levels (0-15) are pre-set. When the stepper motor needs to be started, its frequency will increase step by step from frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com