Photoelectric-isolated high-power brushless direct-current motor drive device and drive feedback processing method

A brushed DC motor, photoelectric isolation technology, applied in the direction of single motor speed/torque control, electronic commutator, etc., can solve the problem of damage to the motor and main controller, little influence on the normal operation of the system, and interference with the normal operation of the drive control system and other problems to achieve the effect of improving stability and efficiency, improving electromagnetic interference and electromagnetic compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0029] This embodiment is used to drive a high-power brushless DC motor in a photoelectric isolation type, and the high-power brushless DC motor is used as an underwater vehicle propulsion actuator.

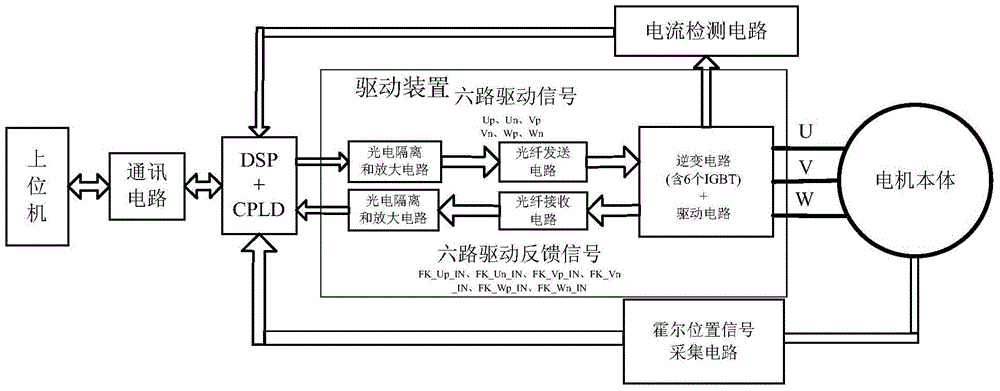

[0030] Refer to attached figure 1 , as can be seen from the figure, the brushless DC motor control system is composed of the upper computer, communication circuit, DSP+CPLD controller, inverter circuit, drive device, current detection circuit, Hall position signal acquisition circuit and motor body.

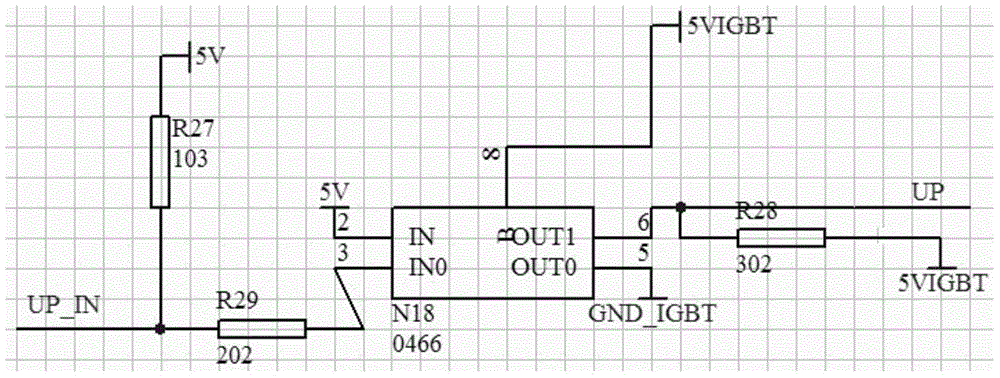

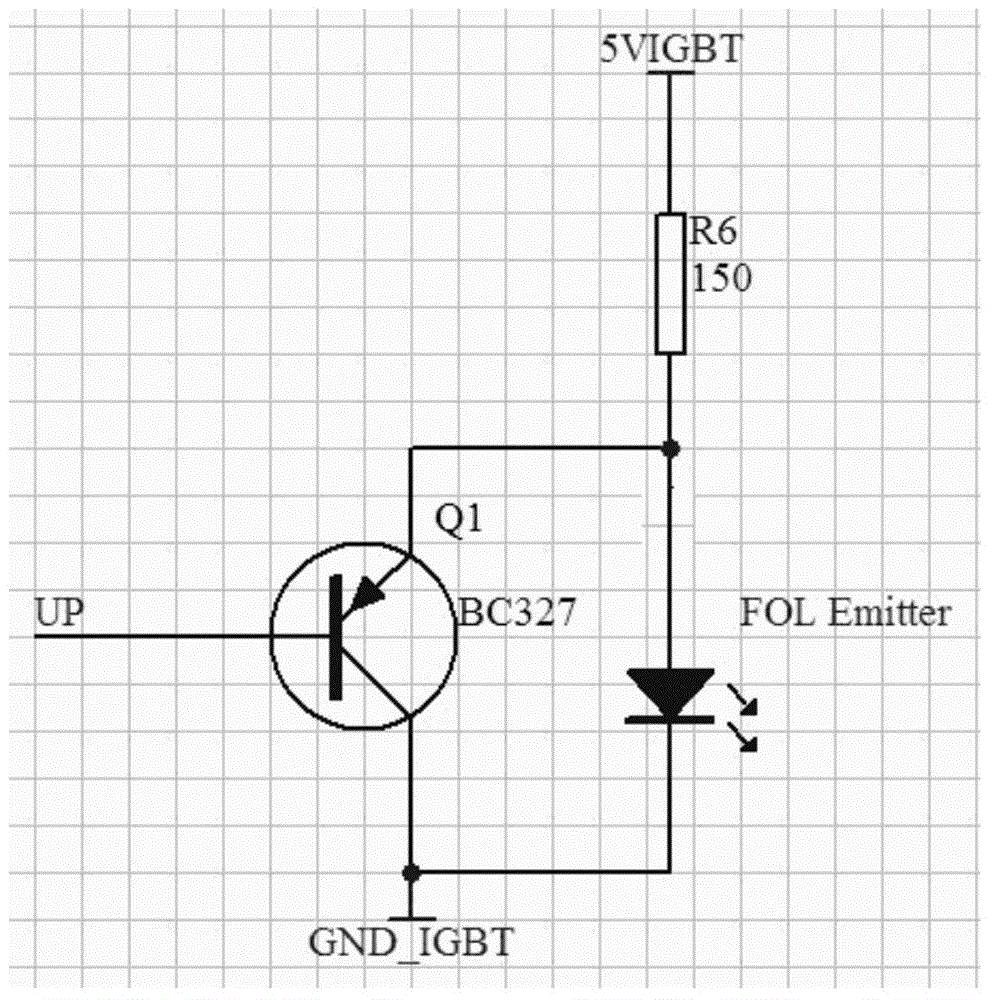

[0031] The drive device includes two drive signal photoelectric isolation and amplification circuits, an optical fiber transmission circuit, an optical fiber reception circuit and a drive circuit; the input end of the first drive signal photoelectric isolation and amplification circuit receives the 6 output signals of the commutation control DSP of the brushless DC mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com