D.C. Voltage conversion electric appliance

A DC voltage, conversion circuit technology, applied in the direction of converting DC power input to DC power output, adjusting electrical variables, instruments, etc., can solve problems such as large power loss, switching loss, power loss in reverse recovery time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

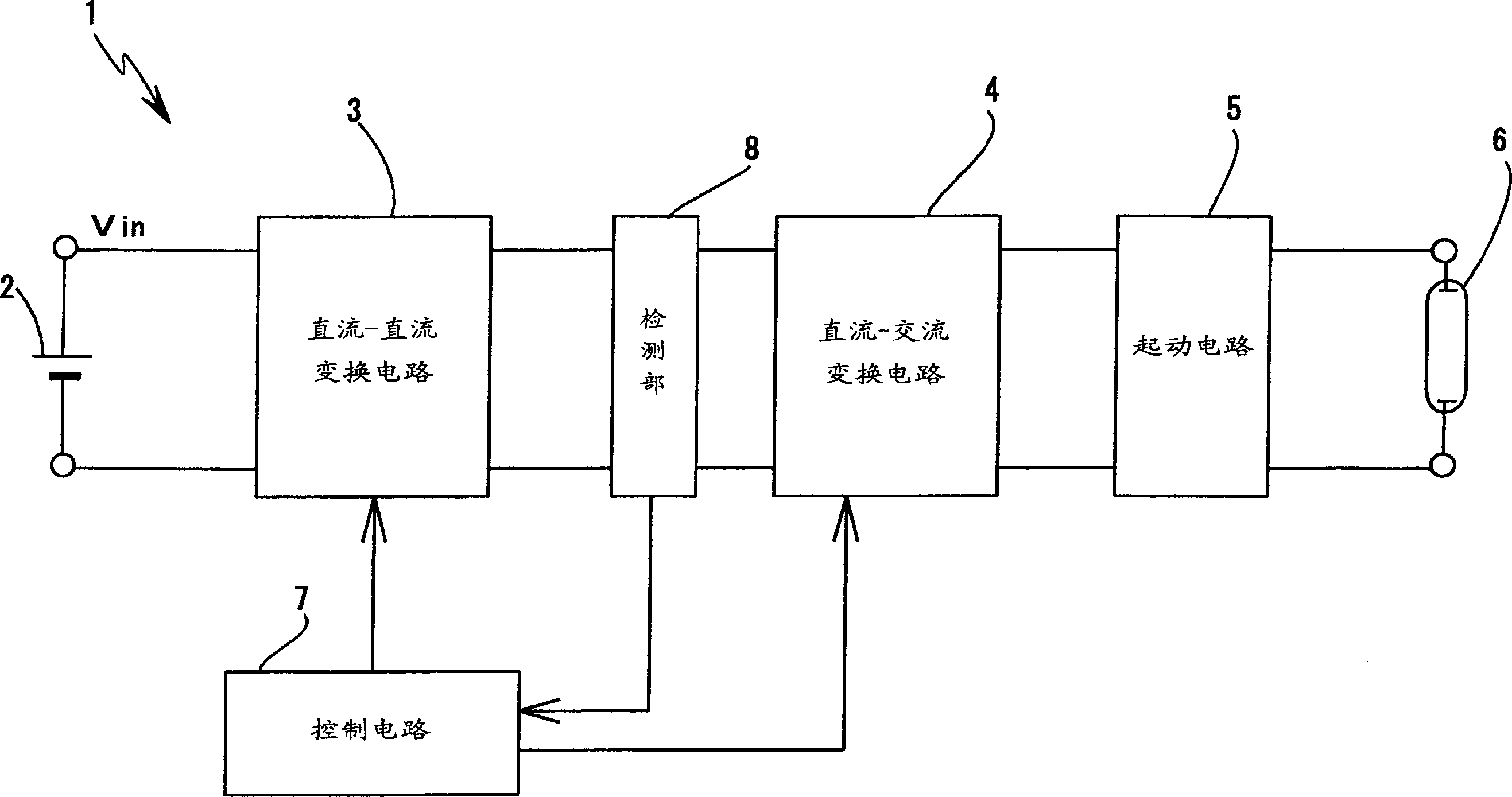

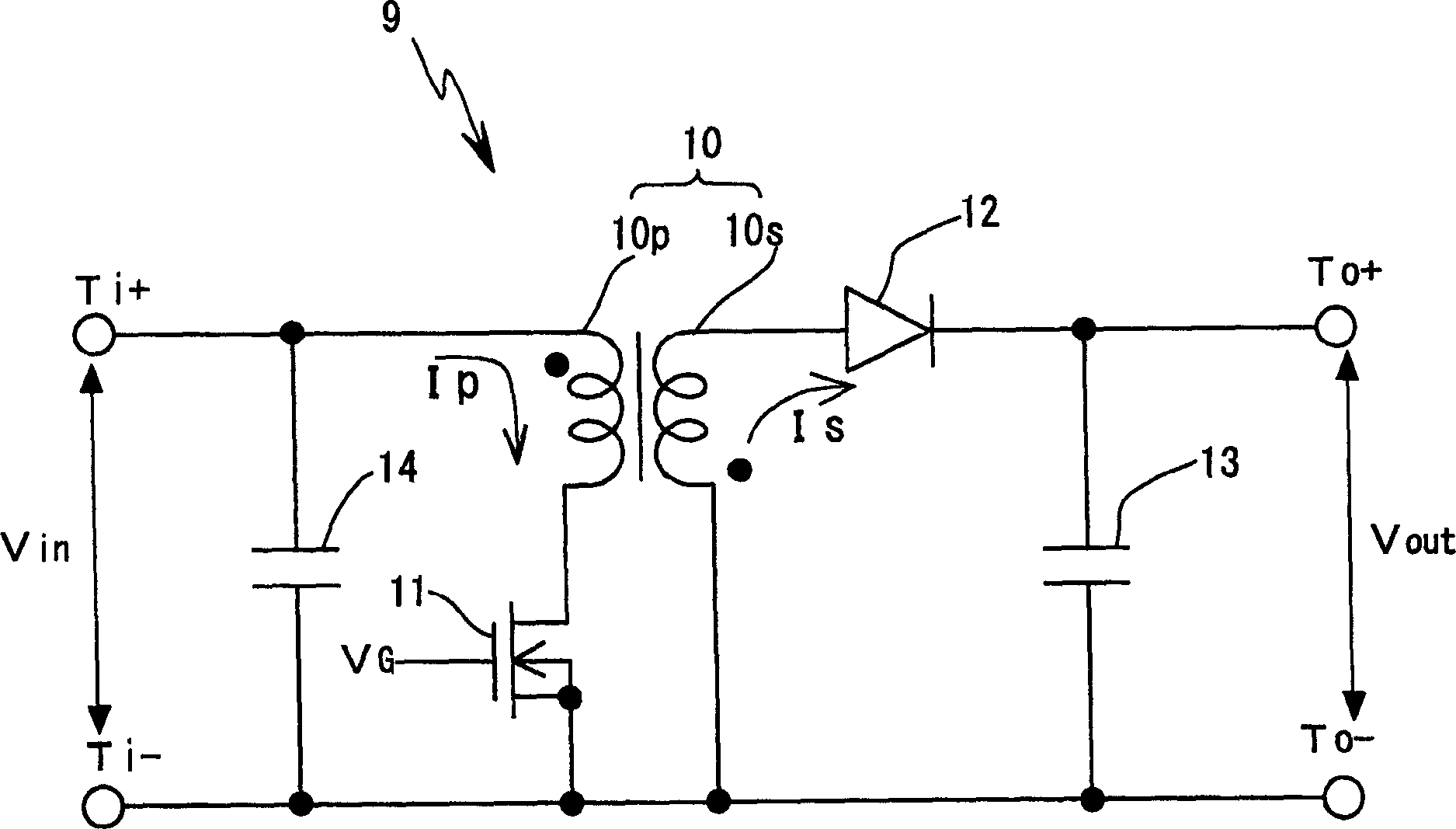

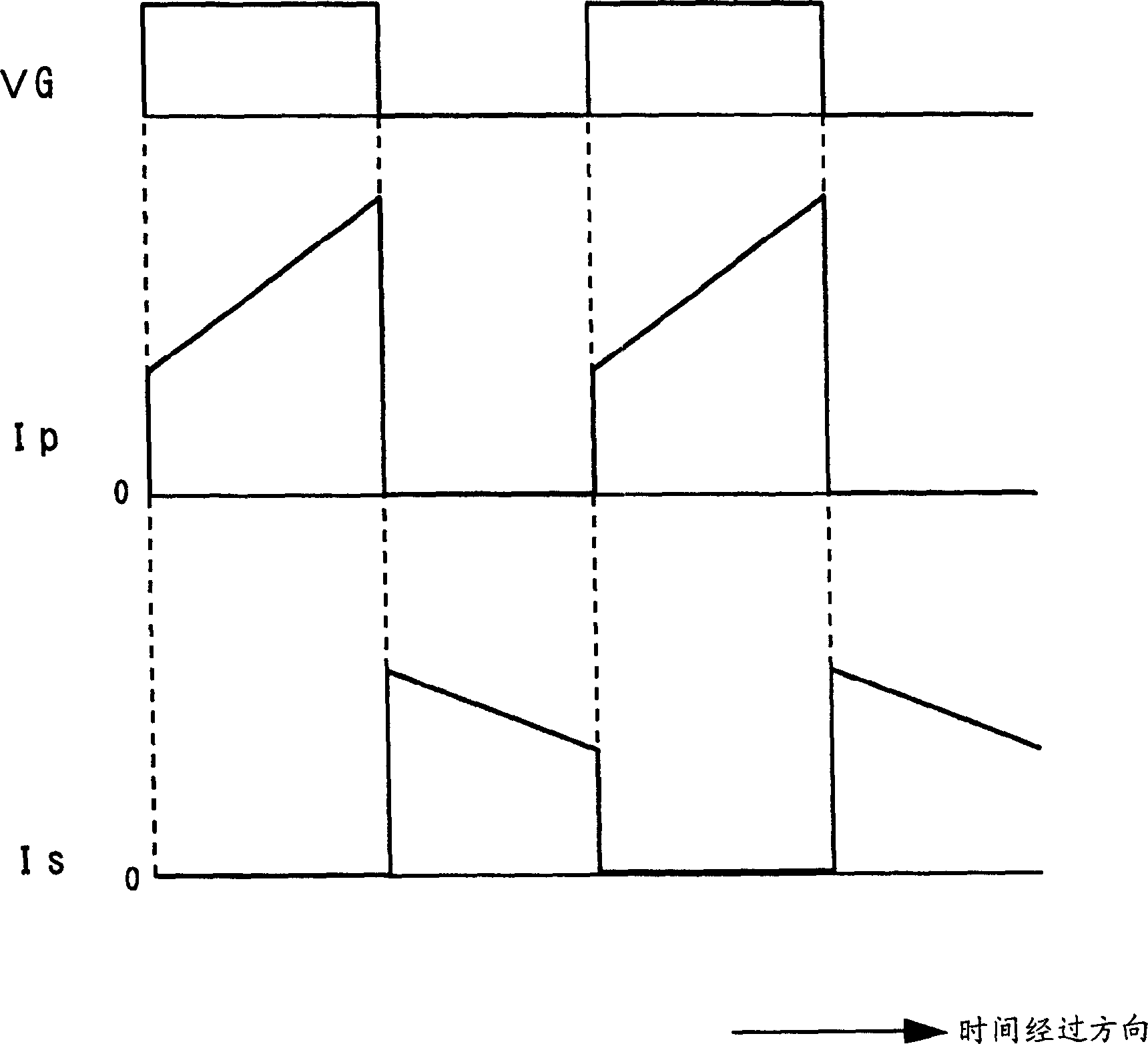

[0026] The DC voltage conversion circuit of the present invention has a feedback type circuit structure including a transformer and a switching element provided on the primary side of the transformer, the transformer stores energy when the switching element is in an on state, and the switching element is in an off state. This energy is output from the secondary winding. In the present invention, by performing the drive control of the current boundary mode described later, it is suitable for the improvement of electrical efficiency, the miniaturization of the circuit device, and the cost reduction. For example, it can be applied to a discharge lamp ignition circuit (especially as a vehicle lamp) In a discharge lamp such as a metal halide lamp as a light source, the ignition circuit when the installation space of the device including the ignition circuit is restricted), but is not limited thereto, and can be widely used in various applications such as power supply circuits.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com