Heat exchanging ventilating apparatus

A ventilation device and heat exchange element technology, which is applied in household heating, heating methods, household heating, etc., can solve the problems of air not flowing through, unable to ventilate, and icing and blocking of air passages, so as to suppress condensation , high reliability, and the effect of reducing the diameter of the air path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

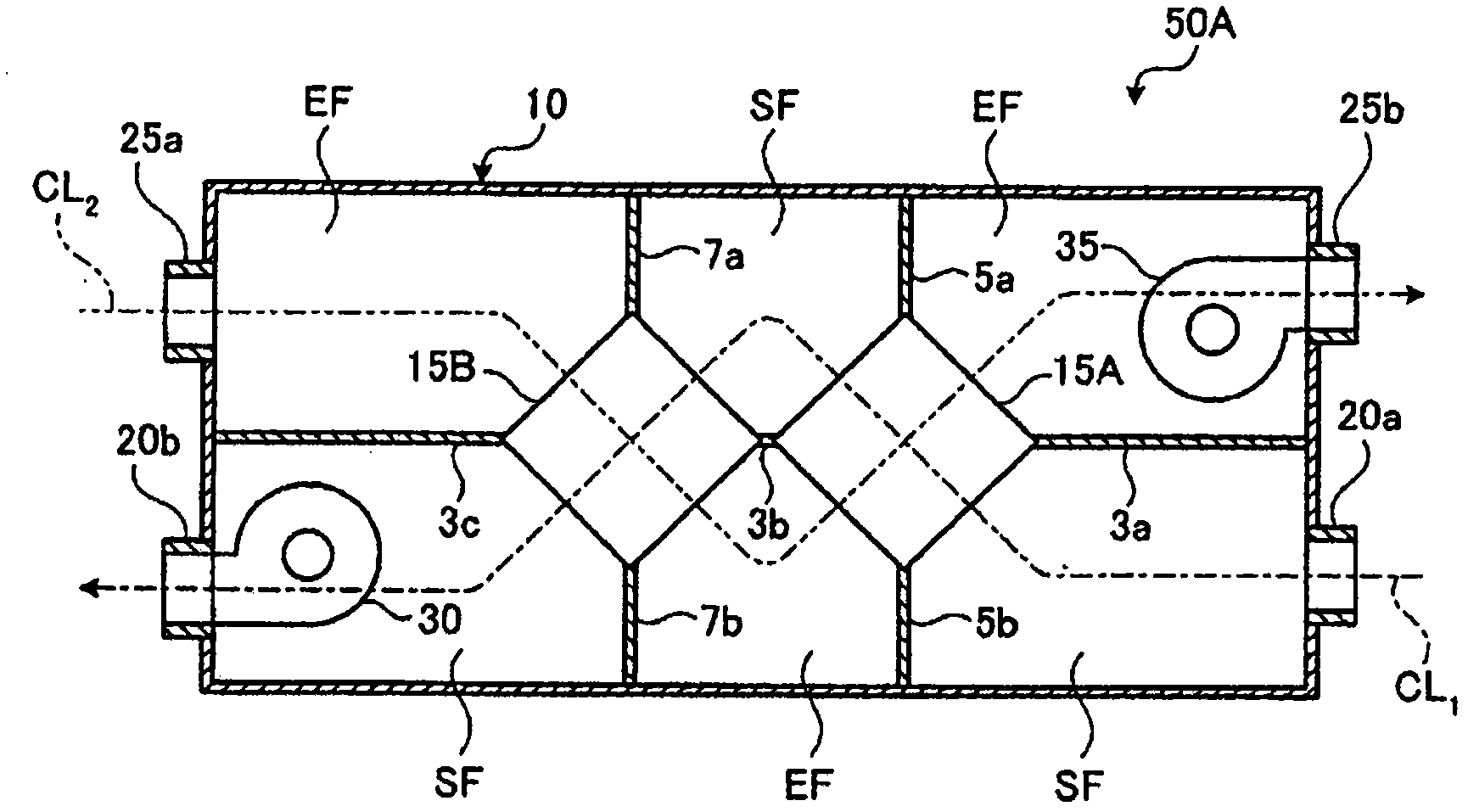

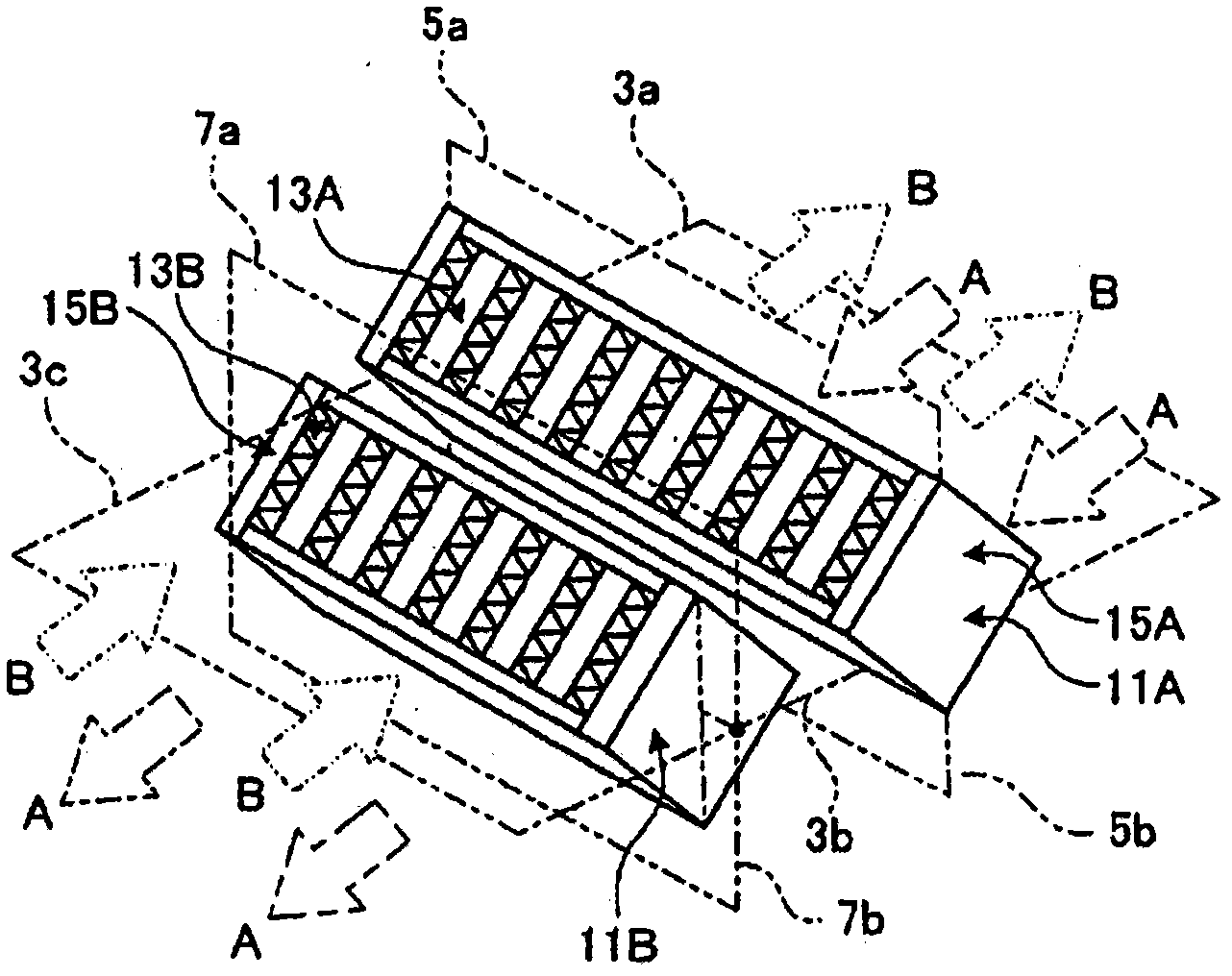

[0043] figure 1 It is a longitudinal sectional view schematically showing an example of the heat exchange ventilator of the present invention. figure 2 is roughly figure 1 The perspective view of the two heat exchange components used in the shown heat exchange ventilator. figure 2 The components shown in the figure 1 If the constituent parts shown are the same, mark with figure 1 The tags in the same tag.

[0044] figure 1 The shown heat exchange and ventilation device 50A has: a frame body 10, two heat exchange assemblies 15A, 15B arranged in the central part of the frame body 10, an outside air suction port 20a installed on the frame body 10, and an outside air blower. Outlet 20b, room air suction port 25a and room air blowing port 25b, air supply fan 30 arranged in frame 10, exhaust fan 35 arranged in frame 10, control function of air supply fan 30 and exhaust fan 35 Action control unit (not shown).

[0045] Three horizontal partition walls 3a, 3b, and 3c and four ...

Embodiment approach 2

[0062] The heat exchange efficiency of the heat exchange element can be adjusted by changing the volume and heat transfer area of the heat exchange element. In addition, the latent heat exchange efficiency can also be adjusted according to the material of the heat exchange element, the amount and type of the moisture absorbent contained. In the heat exchange and ventilation device of the present invention, the heat exchange efficiency of each heat exchange element can be adjusted by adjusting the volume and heat transfer area of the heat exchange element, or the amount and type of moisture absorbent contained in the heat exchange element.

[0063] Figure 4 It is a longitudinal sectional view schematically showing an example of a heat exchange ventilator that adjusts the heat exchange efficiency of each heat exchange element by changing the respective volumes and heat transfer areas of a plurality of heat exchange elements. exist Figure 4 Of the constituent parts shown,...

Embodiment 1

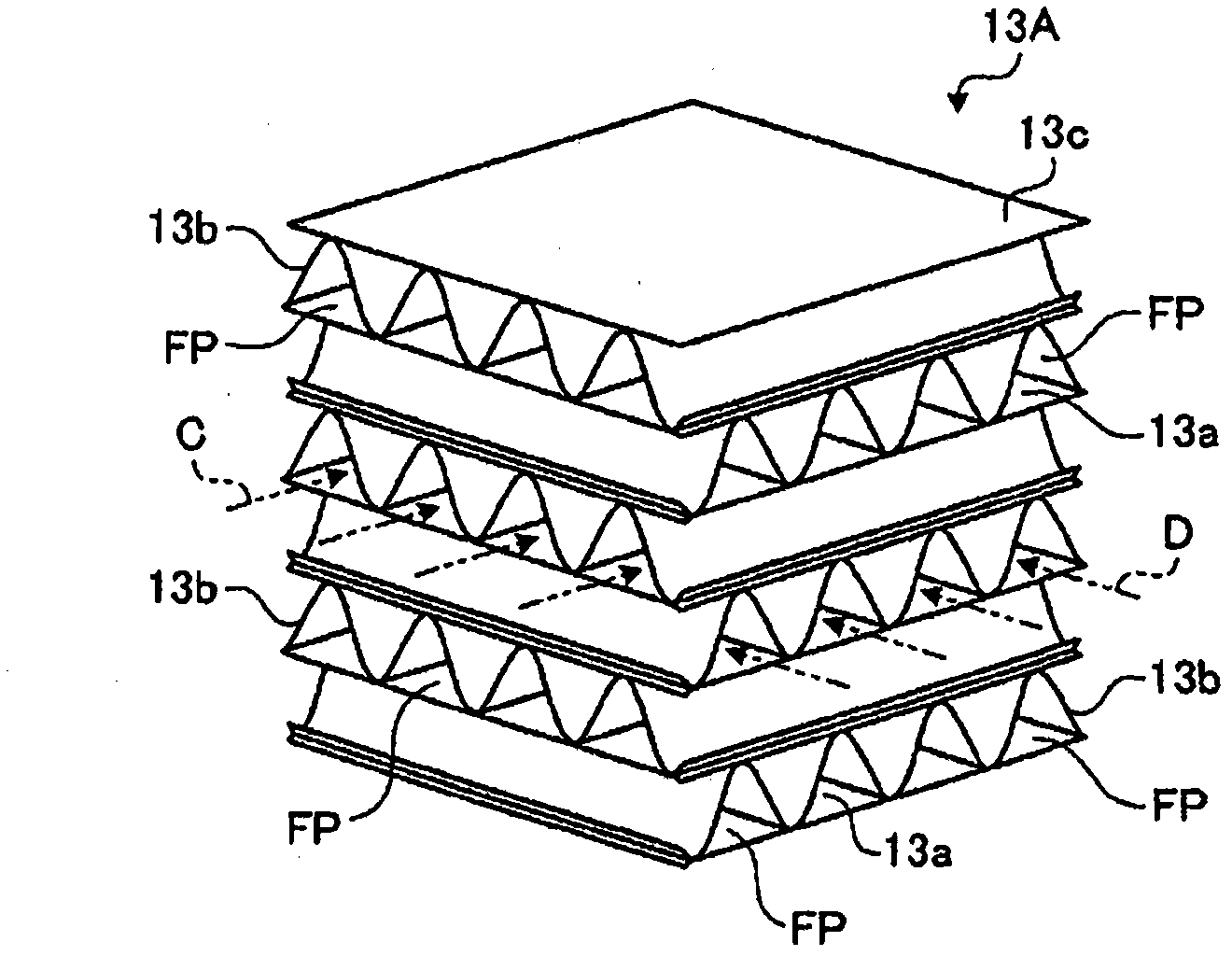

[0074] As the heat exchange element arranged on the outdoor side and the heat exchange element arranged on the outdoor side, a Figure 3-1 The cross-flow total heat exchange element of the same structure as the shown heat exchange element 13A is obtained with figure 1 The heat exchange ventilator 50A shown is a similarly constructed heat exchange ventilator.

[0075] At this time, the partition member in the total heat exchange element disposed on the outdoor side is made of a composite moisture-permeable membrane. This composite moisture-permeable membrane is formed as follows. On the surface of a porous sheet made of polytetrafluoroethylene with a thickness of 25 μm, a polyurethane resin containing an oxyethylene group is thinly coated to become non-porous and highly hydrophilic. The molecular film is point-bonded with a breathable nonwoven fabric on the back of the hydrophilic polymer film. The spacer is made of a sheet with a thickness of about 100 μm made by mixing wood...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com