Method for analyzing masks for photolithography

A technology of mask plate and lithography, which is applied in the field of analysis of mask plates used in lithography, and can solve problems such as complex evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

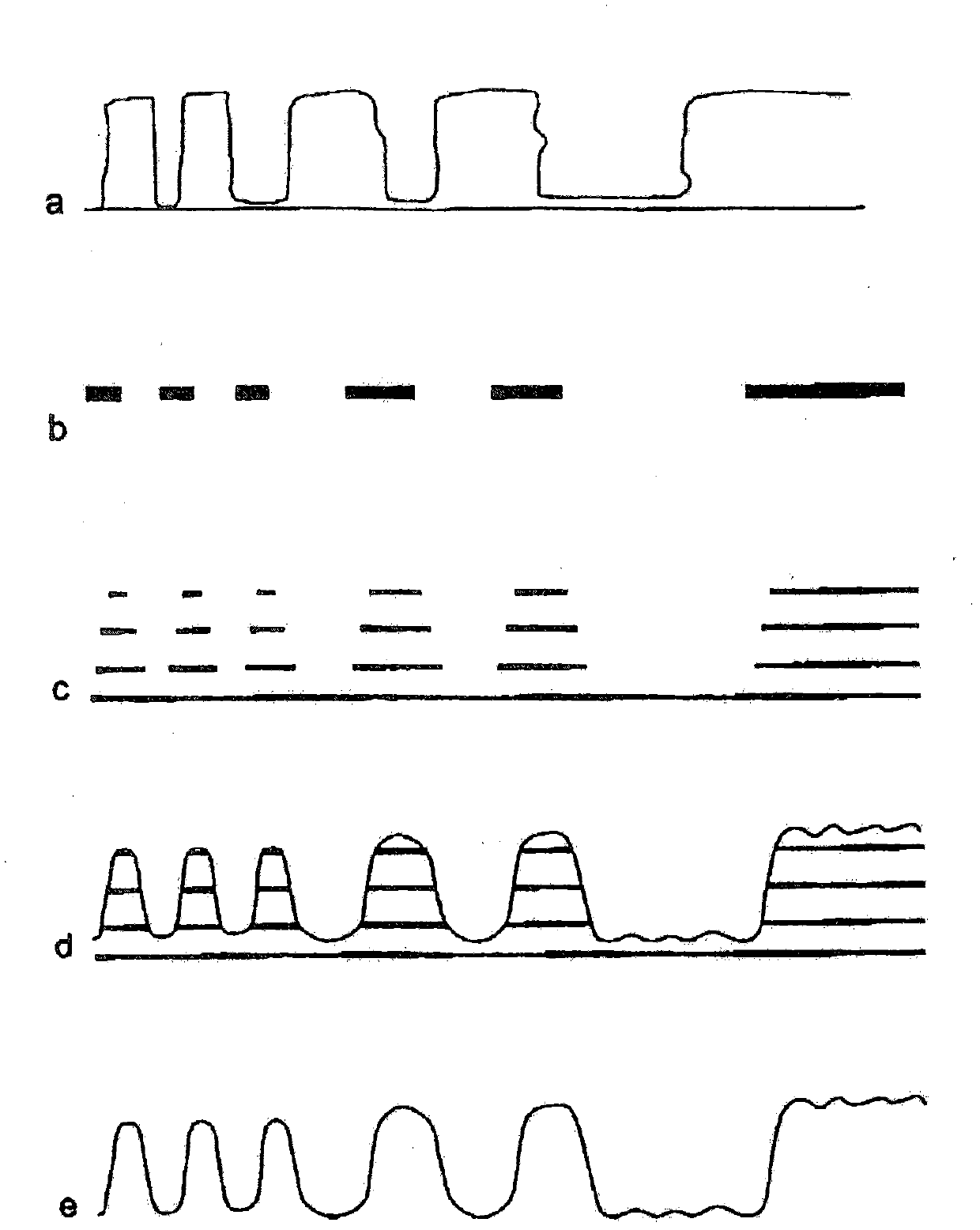

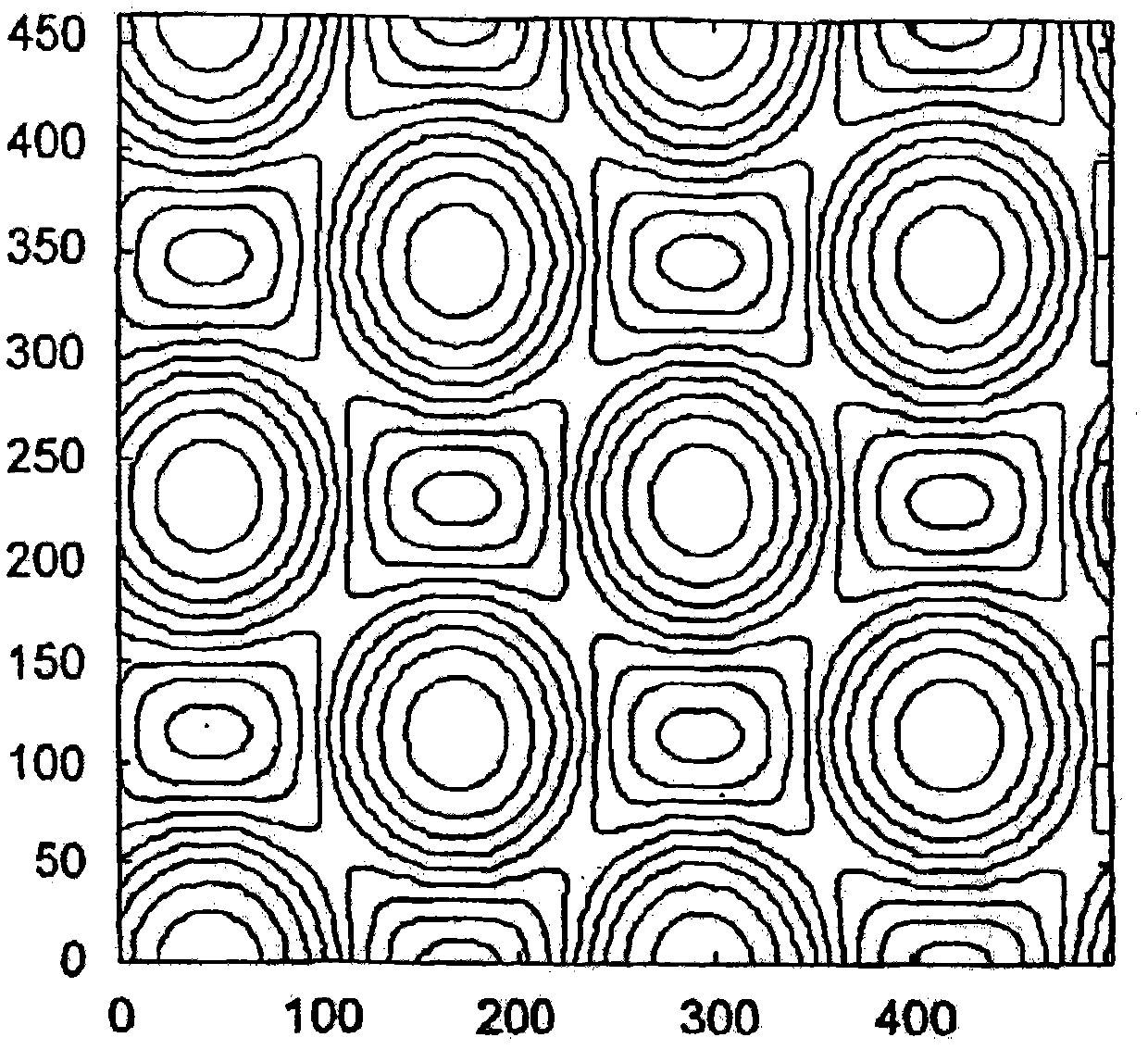

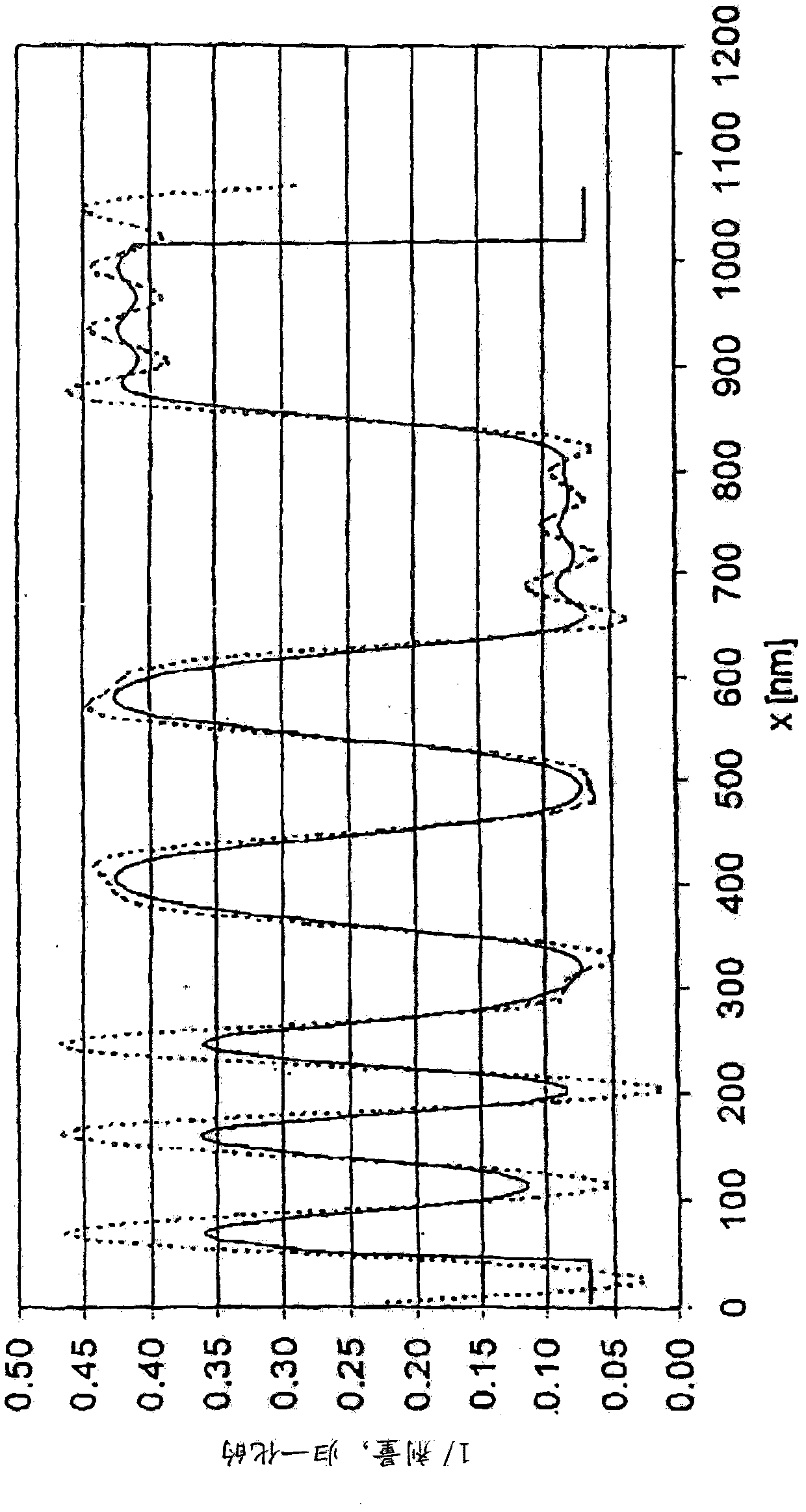

[0030] In a method of analyzing a reticle for lithography, a first step involves recording an aerial image of the reticle at a focus setting. In this case, the focal point is set in a plane that is actually located in the area of the photoresist layer applied to the wafer. Subsequently, the images are digitized and stored in spatial image data records. This spatial image data record is then transferred to an algorithm that simulates the exposure of a lithographic wafer. Exposure and development of a photoresist layer having a predetermined thickness applied to the surface of the wafer is simulated according to predetermined parameters such as energy dose (ie, energy input per unit area). In this case, the aerial image data record defines those locations on the photoresist layer on which light falls and those locations on which light does not shine. Exposure and development are then simulated depending on the type of photoresist. In the case of a positive photoresist, this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com