Bamboo bowl and production method

A production method and technology of bamboo bowls, applied in the direction of plates, wood processing appliances, manufacturing tools, etc., can solve the problems of complex processing, low strength, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

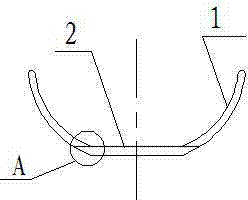

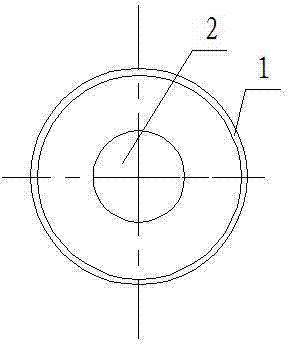

[0028] Depend on figure 1 , figure 2 , image 3 As known, a kind of bamboo bowl, it comprises bowl wall 1, bowl bottom 2, and bowl wall 1 is glued on the bowl bottom 2, and described bowl wall 1 is the lamination of the ring that is processed by bamboo veneer plywood, The bottom of the bowl 2 is a stack of circular plates processed by peeled bamboo veneer plywood.

[0029] A kind of production method of above-mentioned bamboo bowl, it comprises the following steps:

[0030] ⑴Preparation of bamboo peeled veneer plywood;

[0031] Choose straight bamboo with no mildew, decay, moth-eaten fission, no man-made damage, no obvious color difference, no yin and yang sides, the diameter of the brow is more than 10cm, and the part near the bamboo head is 130cm to 430cm for use.

[0032] Cut the selected bamboo into 340mm-350mm (340mm in this example) long bamboo tubes, and keep at least one bamboo node for each section of the bamboo tube when cutting, so as to reduce the longitudinal...

Embodiment 2

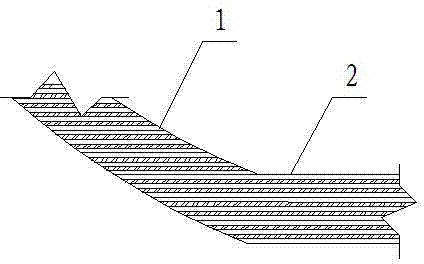

[0045] Depend on Figure 4It can be seen that in order to make the texture of the bowl bottom 2 and the bowl wall 1 consistent, there are annular stripes with different shades and uniform thickness. A kind of bamboo bowl, it comprises bowl wall 1, bowl bottom 2, and bowl wall 1 is glued on the bowl bottom 2, and described bowl wall 1 is the lamination of the circle that is processed by bamboo veneer plywood, and described The bottom of the bowl 2 is processed by coiling and coiling bamboo veneer plywood.

[0046] A kind of production method of above-mentioned bamboo bowl, it comprises the following steps:

[0047] ⑴Preparation of bamboo peeled veneer plywood;

[0048] This embodiment is in the preparation of step (1) bamboo veneer plywood; prepare two kinds of bamboo veneer plywood. It is 320㎜×320㎜×1.00㎜; the other is to prepare 5 layers of bamboo slices with a thickness of 0.44㎜ into five layers of bamboo rotary-cut veneer plywood, with a size of 320㎜×320㎜×2.20㎜.

[0049]...

Embodiment 3

[0055] Depend on Figure 5 It can be seen that in order to make the texture of the bowl bottom 2 and the bowl wall 1 consistent, there are annular stripes with different shades and uniform thickness.

[0056] ⑴Preparation of bamboo peeled veneer plywood;

[0057] This embodiment is in the preparation of step (1) bamboo veneer plywood; prepare two kinds of bamboo veneer plywood. It is 320㎜×320㎜×1.00㎜; the other is to prepare 5 layers of bamboo slices with a thickness of 0.44㎜ into five layers of bamboo rotary-cut veneer plywood, with a size of 320㎜×320㎜×2.20㎜.

[0058] (2) Blank making: According to the diameter of the bamboo bowl at different heights and the thickness of the bowl wall, the bamboo rotary-cut veneer plywood is cut into rings of different sizes as the blank of the bowl wall 1, and the bamboo rotary-cut veneer plywood is wound into a coil As the blank of the bowl bottom 2;

[0059] In step (2) blank making, select five layers of bamboo peeled veneer plywood to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com