Force-controlled rocking-rolling type rolling sealing machine

A sealing machine and rolling technology, which is applied in the field of force-controlled pendulum-rolling rolling sealing machines, can solve the problems of affecting the processing quality and work efficiency, the deviation of the processed workpiece from the processing position, and the large fluctuation of force, so as to improve the processing quality and efficiency. Work efficiency, accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

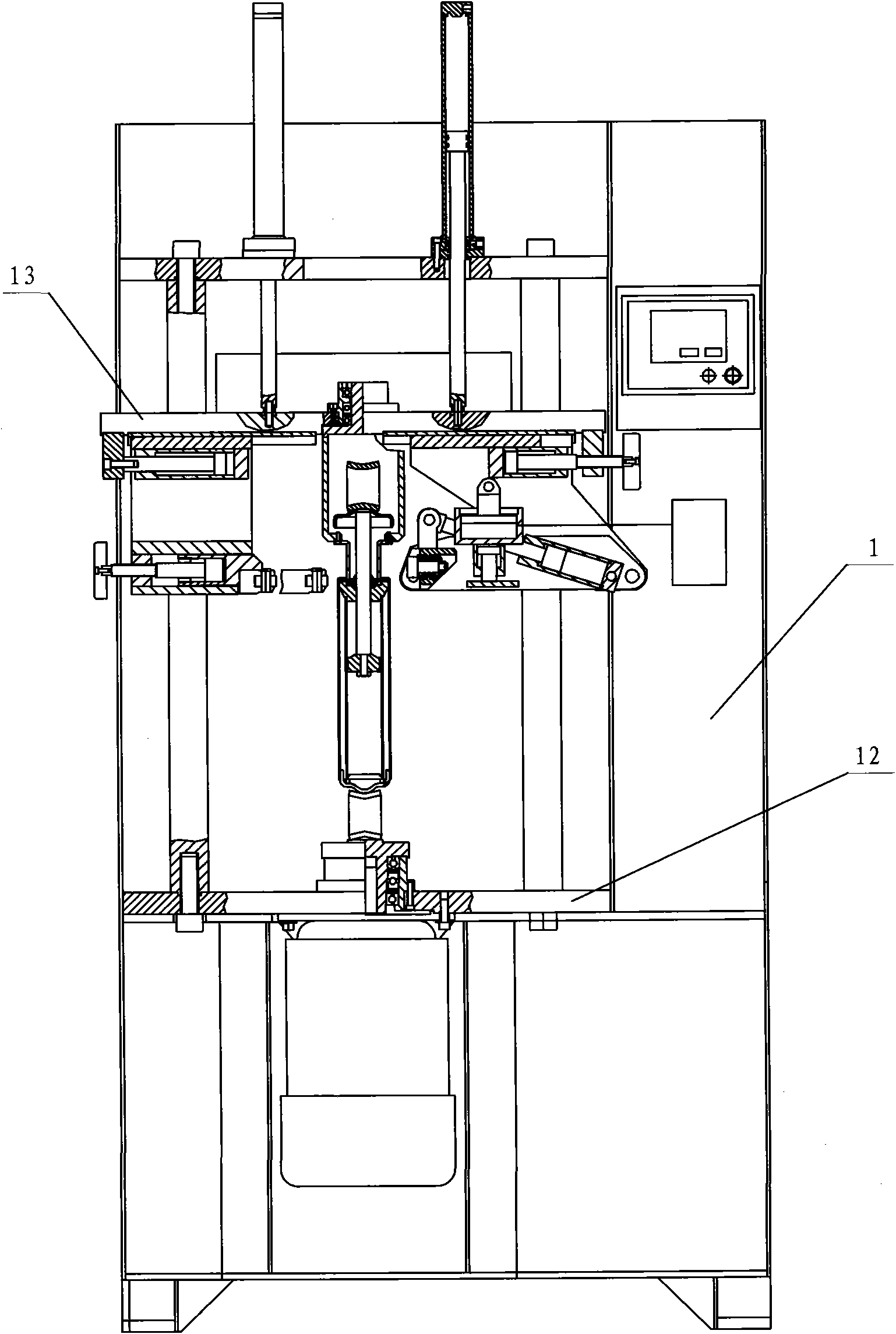

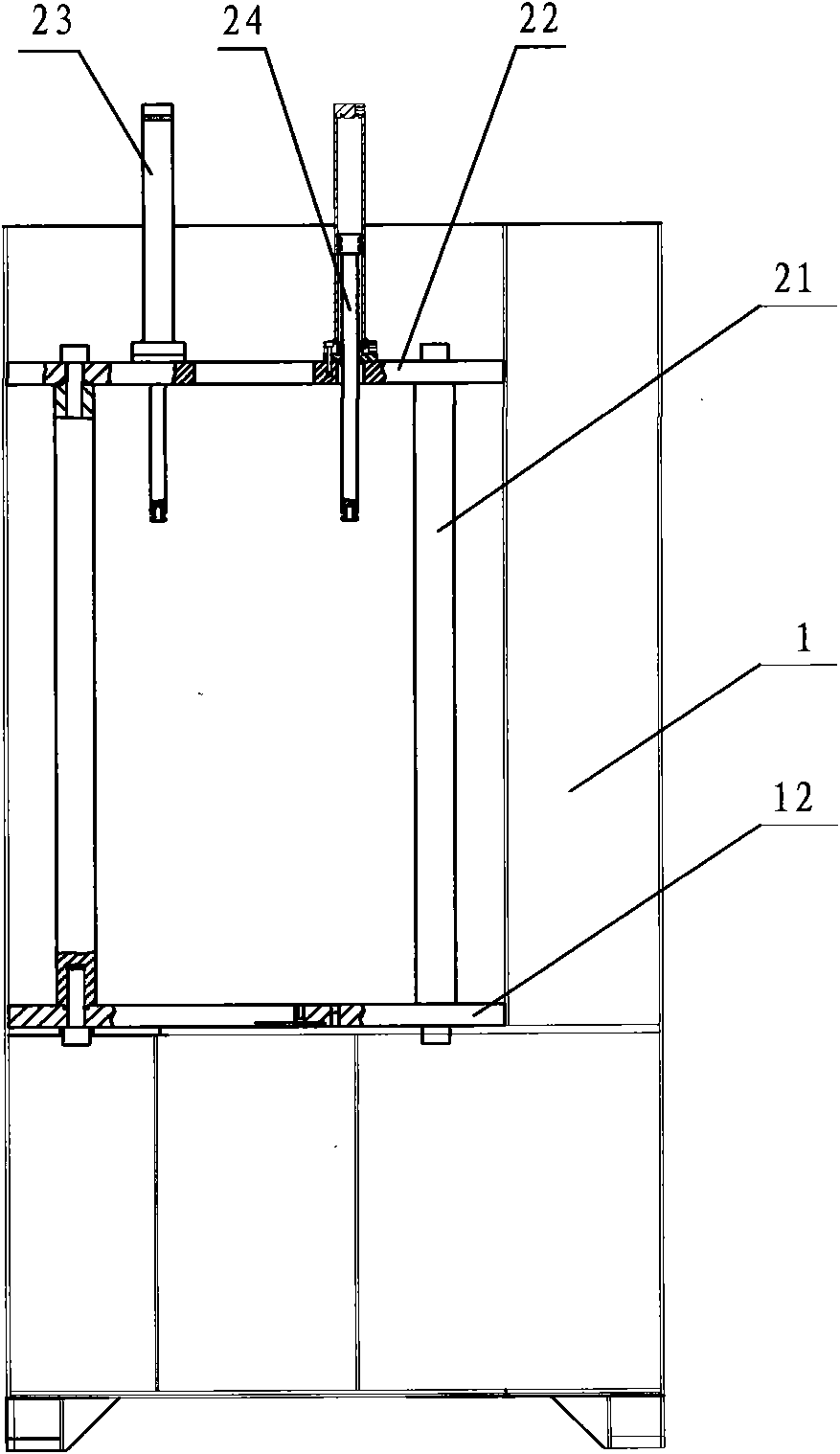

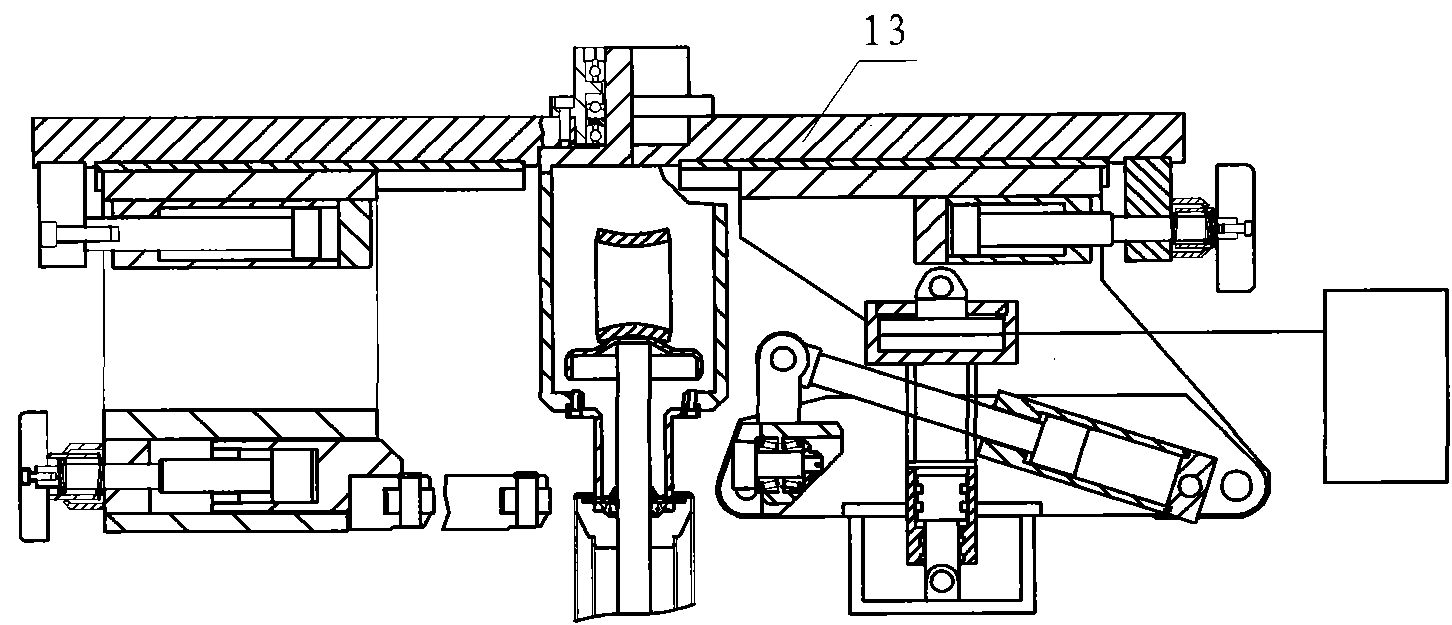

[0023] The force-controlled pendulum roll rolling sealing machine of the present invention includes a frame 1, a fixed worktable 12, a floating workbench 13, a lifting mechanism, a clamping mechanism 4, a rotating mechanism 5, a pendulum rolling mechanism 6 and a pre-tensioning mechanism 3 . see figure 1 with figure 2 , the fixed table 12 is fixed on the bracket 1 by screws, and the fixed table 12 can also be an integral part of the bracket 1 or be welded on the bracket 1 . The lifting mechanism is a four-column mechanism, which is the skeleton of the connection operation and positioning support of the whole machine. It includes a guide column 21, a cover plate 22, a lifting cylinder 23 and a lifting piston rod 24. On the fixed workbench 12 , the cover plate 22 is mounted on the guide post 21 through screw connection, and is located above the fixed workbench 12 , and two lifting cylinders 24 are fixed on the cover plate 22 in parallel. The lower end of the lifting piston r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com