Magnetic pump dosing device

A quantitative device, magnetic pump technology, used in casting molding equipment, molds, cores, etc., can solve the problems of expensive spare parts, high production costs, short service life of films, etc., to achieve long service life, ensure safety, The effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

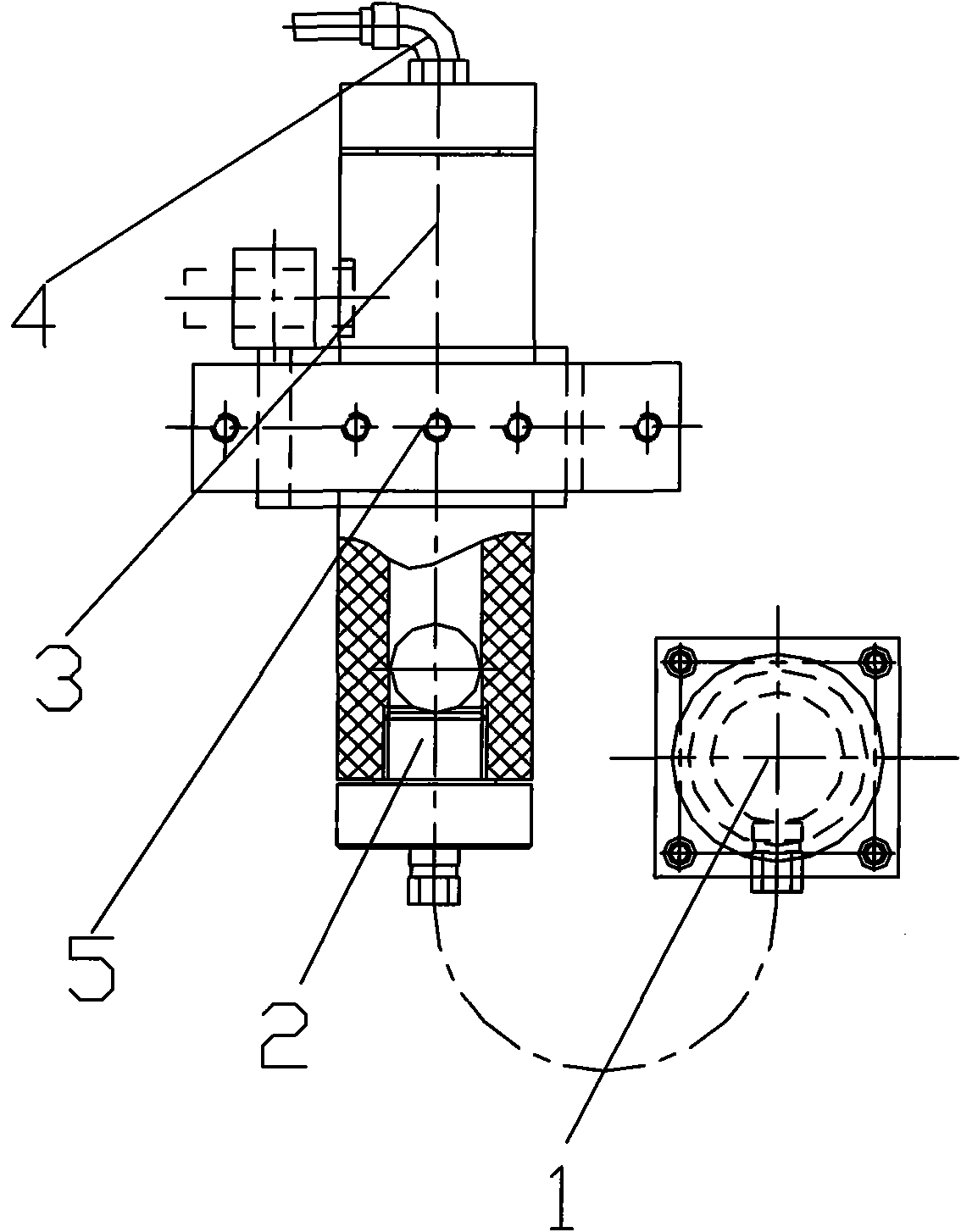

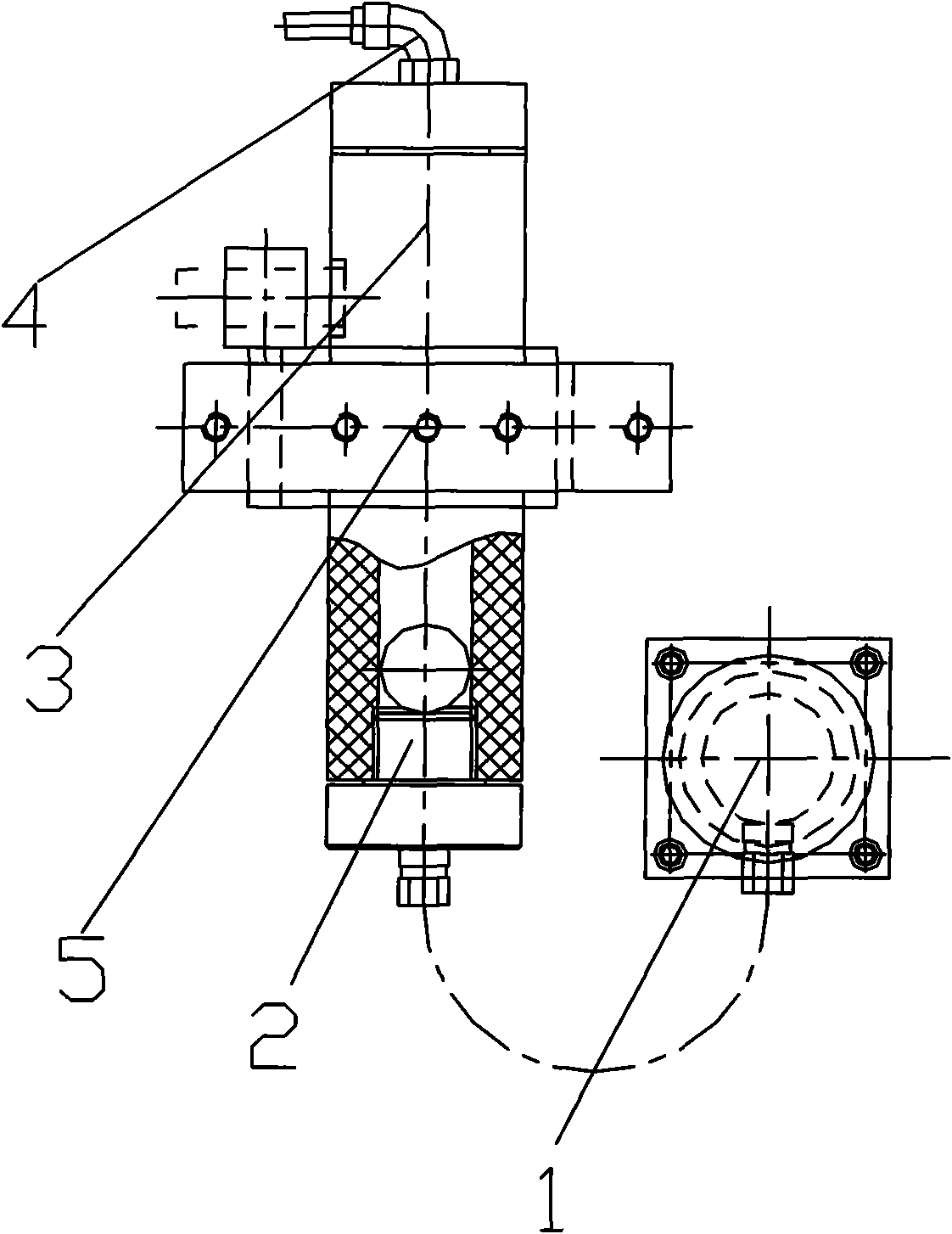

[0012] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the magnetic pump dosing device includes a magnetic pump and a certain measuring cylinder 3, the magnetic pump includes a pump body 2, a magnetic transducer and a motor 1, the magnetic transducer includes an outer magnetic rotor and an inner magnetic rotor, and the pump body 2 is located at the quantitative Inside the barrel 3, the motor 1 is located outside the metering barrel 3, the inner magnetic rotor is connected to the pump body 2, the outer magnetic rotor is coaxially fixedly connected to the motor 1, and the inner magnetic rotor is opposite to the outer magnetic rotor. For the convenience of fixing, the quantitative cylinder 3 is fixed on a support frame 5, and for the convenience of transporting triethylamine, the quantitative cylinder 3 is also provided with a certain measuring tube 4.

[0014] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com