Semi-automatic box gluing machine

A box gluer, semi-automatic technology, applied in the direction of container manufacturing machinery, rigid/semi-rigid container manufacturing, paper/cardboard containers, etc., can solve the problems of short pressing length, low work efficiency, and many people, so as to achieve selection and The effect of increasing and decreasing flexibly, improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

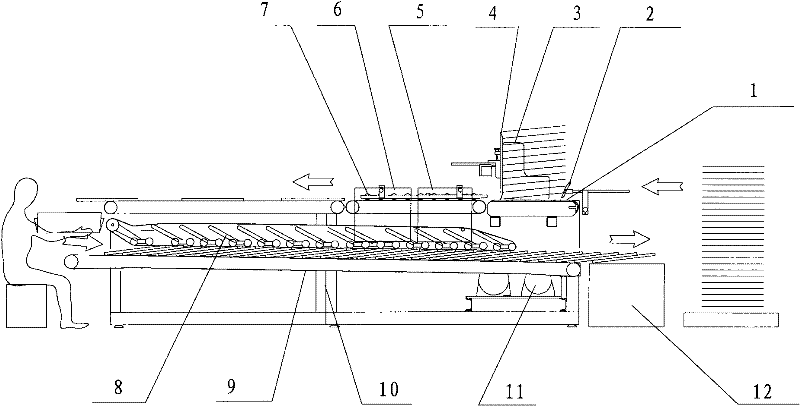

[0020] See figure 1 , Embodiment 1 of a semi-automatic box gluer of the present invention includes a paper feeding conveyor belt 1, a rear rail 2, a side rail 3, a front rail 4, a grinding and gluing mechanism, a pressure conveying part, a paper delivery table 12, and pressure conveying The part includes a frame, a transmission mechanism composed of a motor 11 and a conveyor belt 9, and a pressure mechanism 8 on the frame. The frame of the pressure transmission part is divided into at least two sections along the transmission direction. Offline 10, the total transmission length of the frame of the compression section is at least 3 meters. The grinding and gluing mechanism is divided into an independent grinding module 5 and a gluing module 6. It is convenient to choose left and right gluing or add left and right grinding modules. There is a pressing wheel 7 in the gluing module 6.

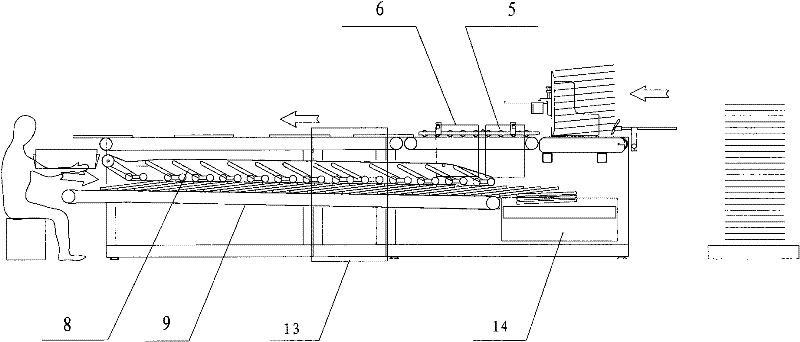

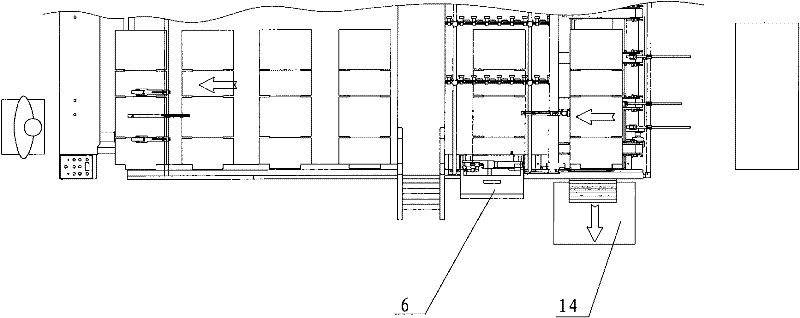

[0021] See figure 2 , image 3 , Embodiment 2 of a semi-automatic box gluer of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com