Pneumatic conveying method for powder materials

A technology for pneumatic conveying and materials, applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problem that the pneumatic ash removal system is difficult to meet the economic, practical, reliable, energy-saving, and the down-drawing warehouse pump is difficult to control the discharge speed , Conveying compressed air and conveying low efficiency of dry ash, to achieve the effect of saving equipment and materials, saving warehouse pumps and valves, and facilitating the speed of ash discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The powder material delivery method provided by the invention will be further described in detail below in conjunction with the accompanying drawings:

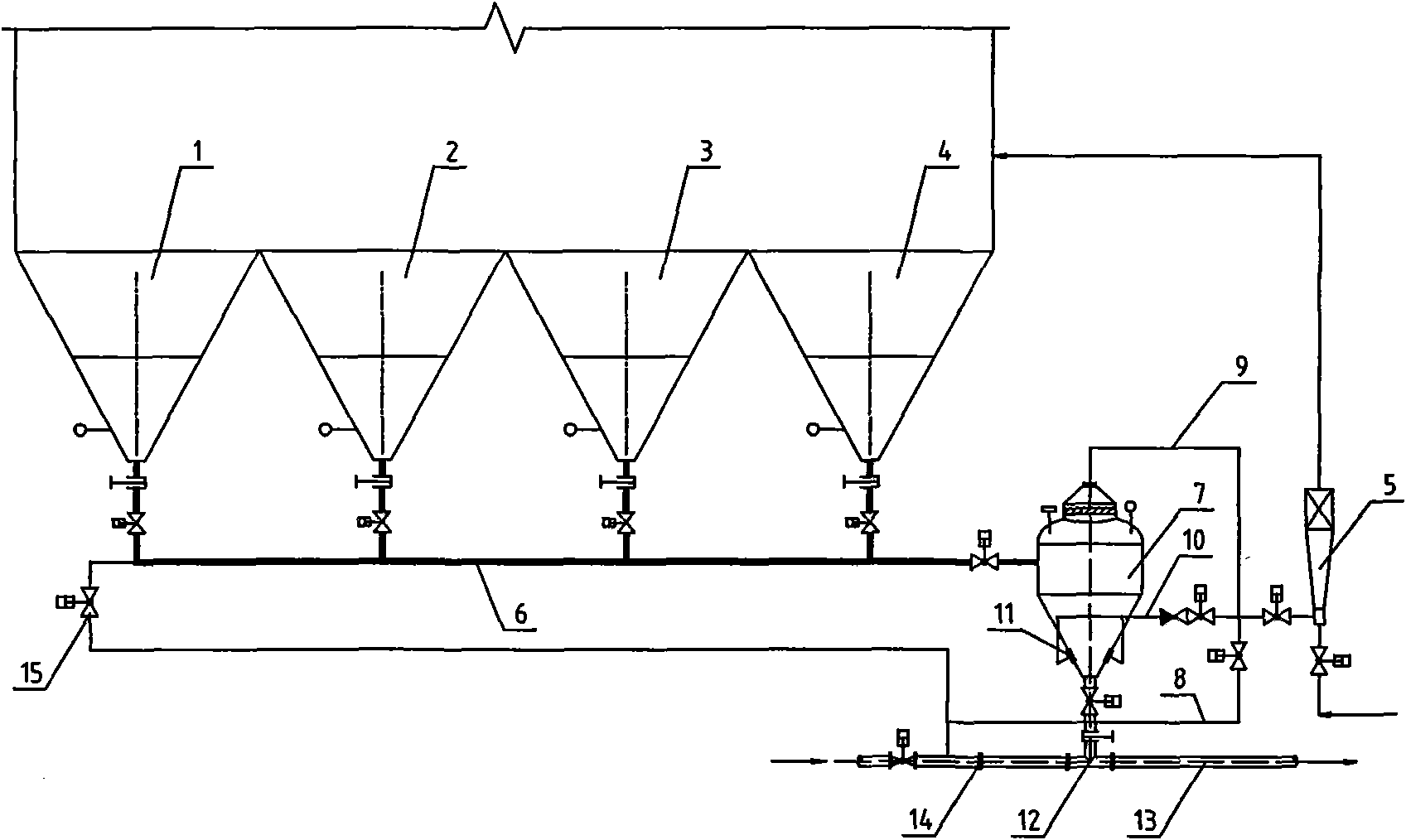

[0020] Such as figure 1 As shown, the warehouse pump produces negative pressure device 5 to generate negative pressure in the warehouse pump 7, and the end section of the negative pressure ash conveying pipeline 6 away from the warehouse pump is provided with a positive pressure air supply device 15, and the positive pressure air supply device 15 is opened to dry air. The ash forms a thrust, and under the joint action of negative pressure suction, positive pressure thrust, and dry ash self-weight, the dry ash in the ash hoppers 1, 2, 3, and 4 enters the warehouse pump 7 through the negative pressure conveying pipeline 6, and the negative pressure ash loading is completed;

[0021] The compressed air pressurizes the warehouse pump through the pressurized fluidization pipeline 8 through the pressurization pipeline 9, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com