Overload lowering prevention monitoring system of main shaft friction type hoister

A hoist, friction-type technology, applied in the field of anti-heavy-load lowering monitoring system of friction-type hoist in the main shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0019] The present invention is realized through the following technical solutions:

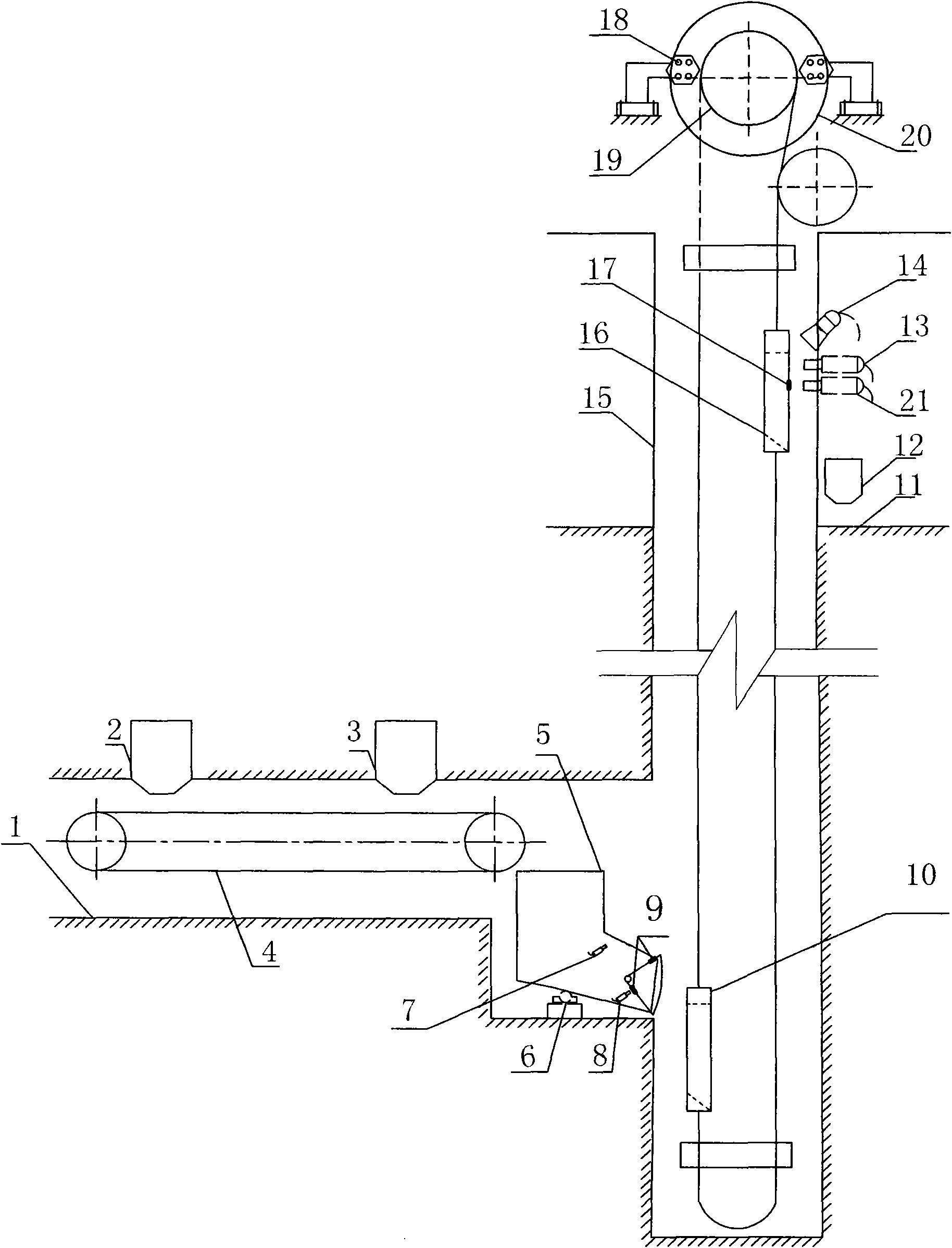

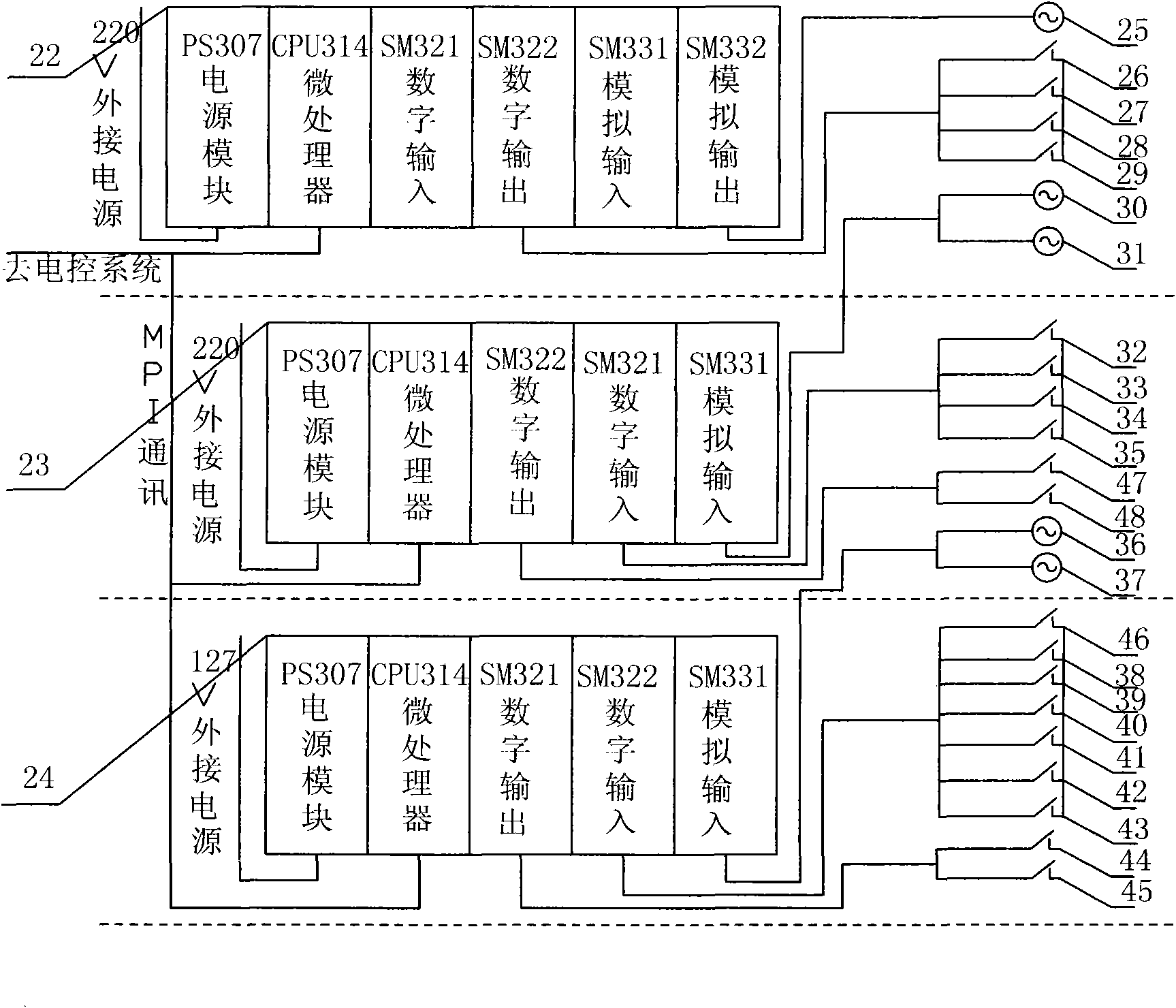

[0020] The main shaft friction hoist anti-heavy load lowering monitoring system of the present invention is mainly composed of three parts: a main shaft loading monitoring center, a main shaft unloading monitoring center, and a main shaft hoisting machine room monitoring center.

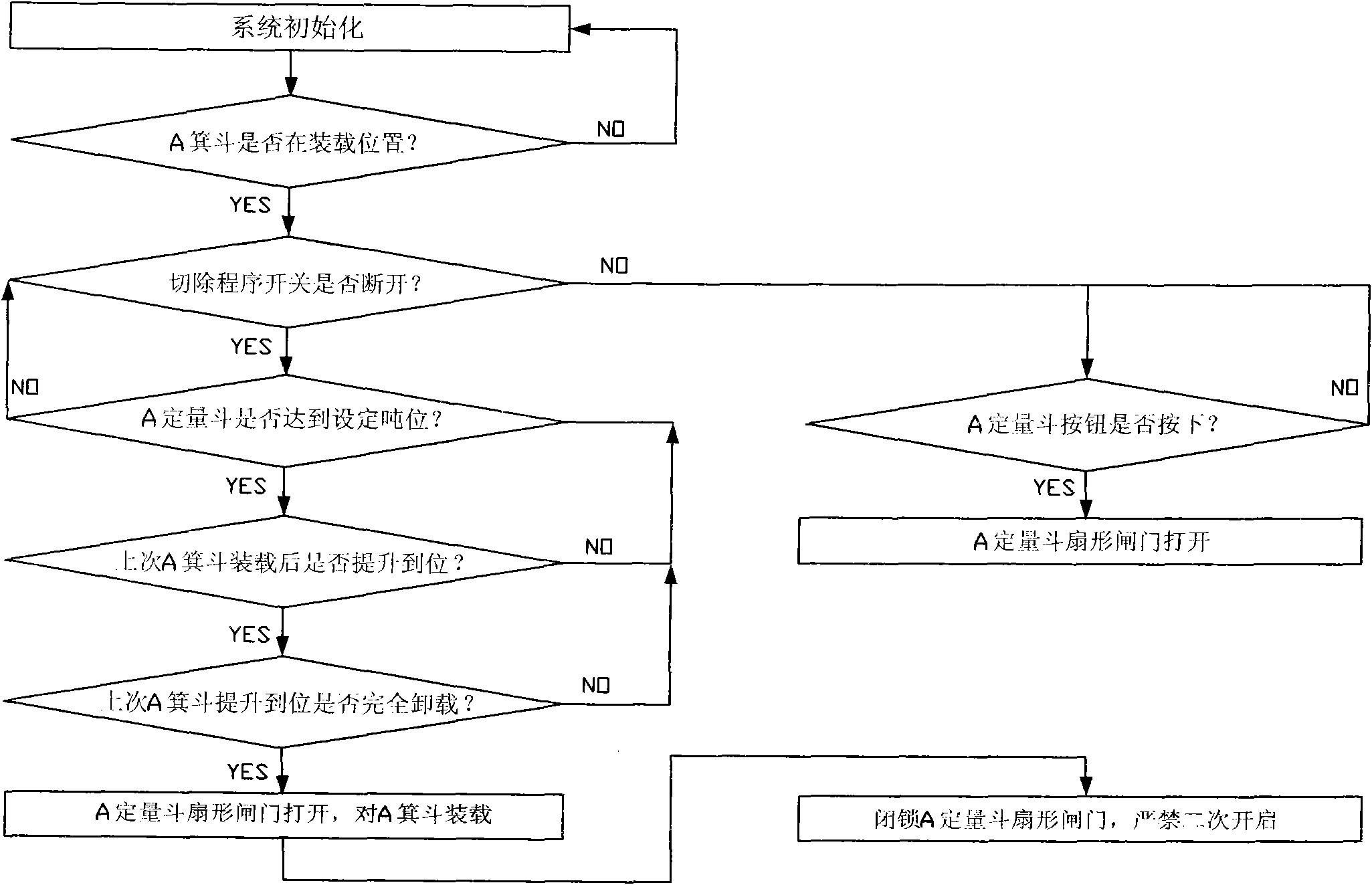

[0021] The main well loading monitoring center of the present invention is mainly composed of S7-300 programmable controller, quantitative bucket control button, quantitative bucket fan-shaped door opening sensor, quantitative bucket fan-shaped door closing sensor, quantitative bucket weighing sensor, quantitative bucket fan-shaped gate switch solenoid valve and so on. The main shaft loading monitoring center mainly completes the functions of manual and automatic switch control of the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com