Converter oxygen lance blowing control method based on dry dedusting process

A converter oxygen lance and dry dust removal technology, which is applied in the manufacture of converters, etc., can solve the problems that the dry dust removal converter blowing control technology has not yet been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

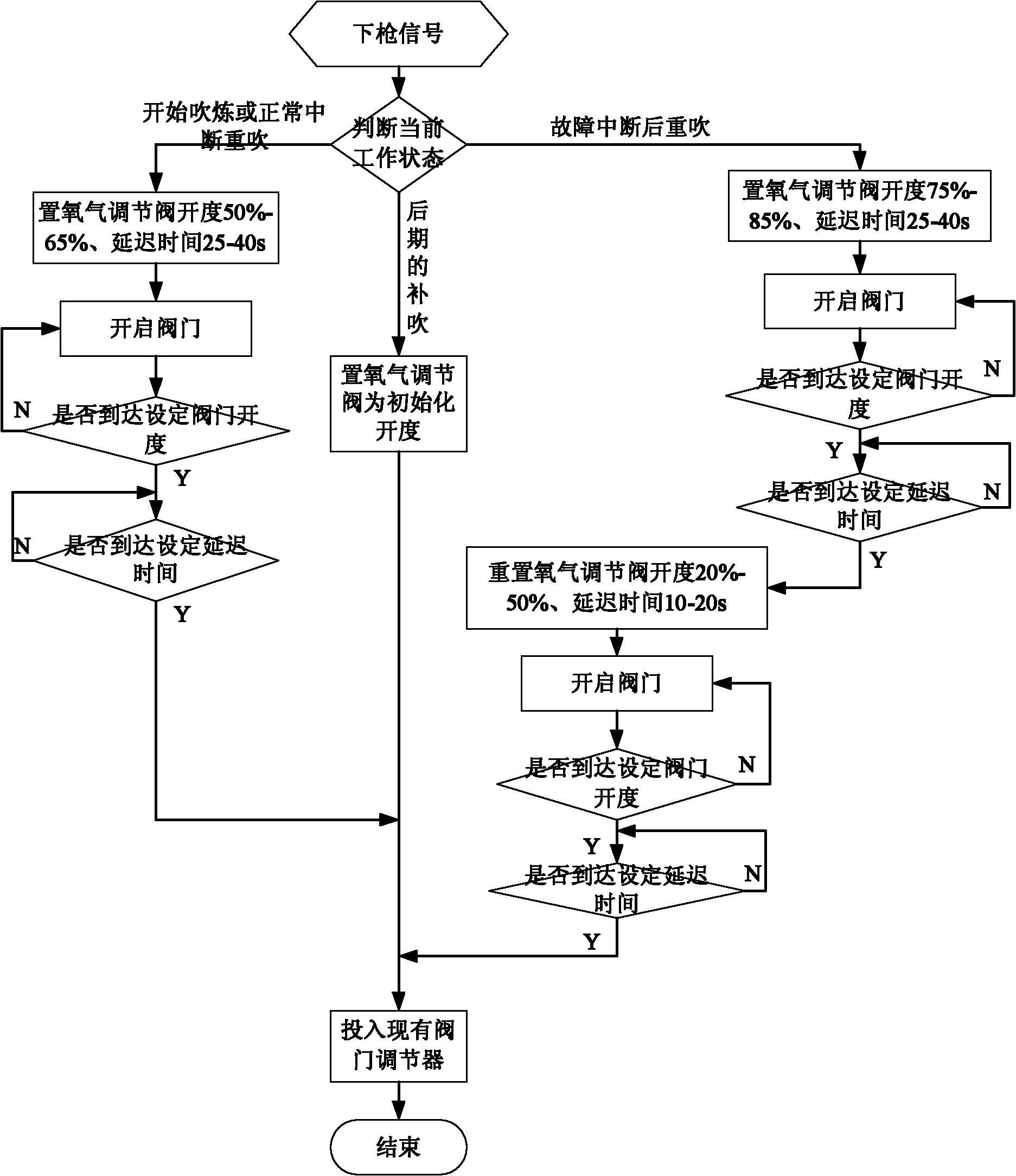

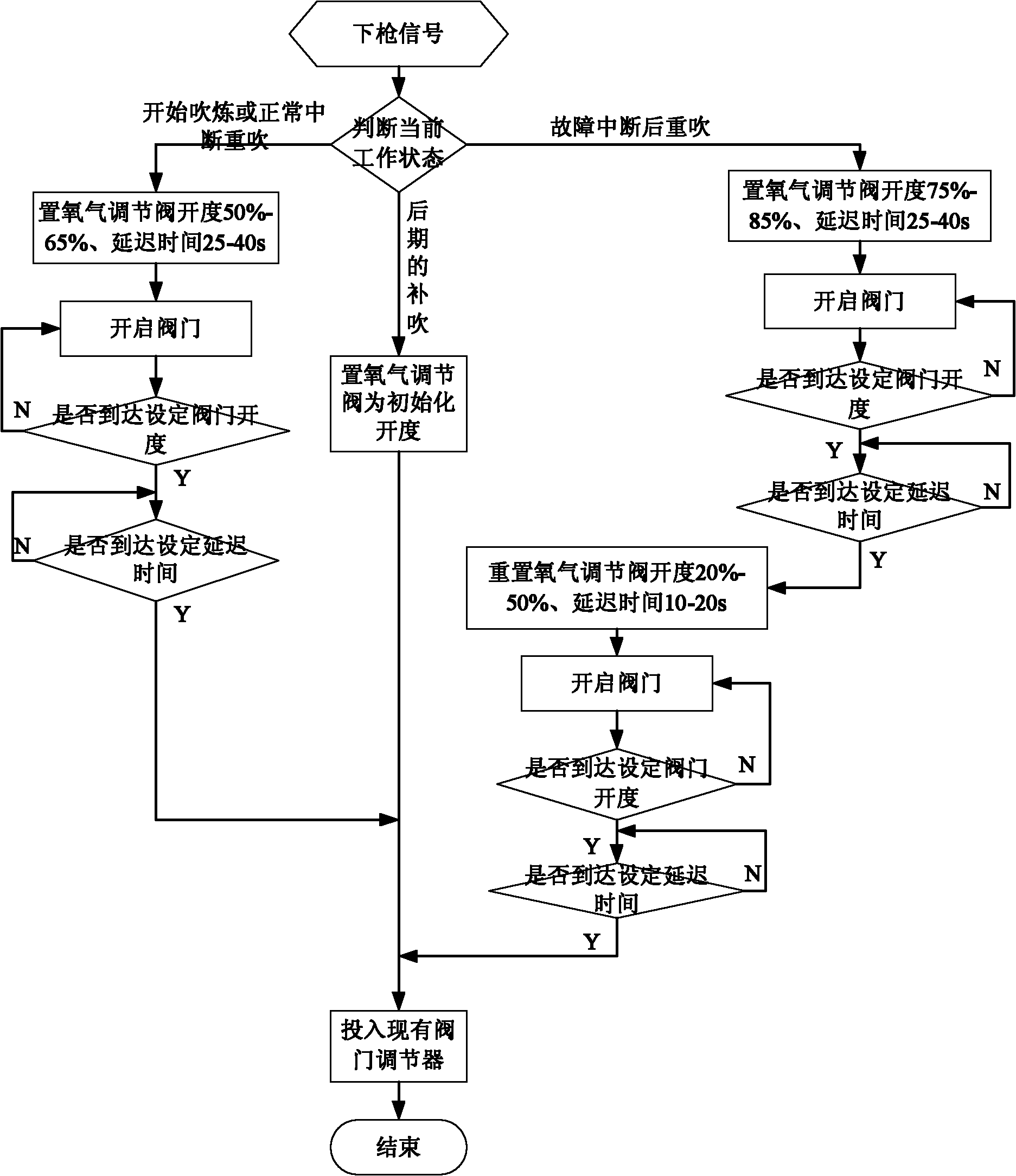

[0018] The classic converter blowing control process is based on the preset valve position of the oxygen regulating valve, which is directly input into the valve regulator PI for automatic adjustment. As a result of this control, the O entering the furnace at the beginning of blowing 2 Too late to be oxidized by molten iron (Fe 3 o 4 =2O 2 +3Fe) leads to O in the flue gas 2 The content is relatively large. This has no major impact on traditional wet dust collection. However, for dry dedusting process with ESP, high O 2 Concentrated flue gas passing through the electrostatic precipitator will cause the risk of explosion venting accidents, making steelmaking unable to proceed normally. After the initial stage of blowing, the amount of oxygen blowing in the steelmaking furnace reaches the set value, the oxidation-reduction reaction in the furnace tends to be stable, and the oxygen in the flue gas 2 The content decreases and maintains a certain value, which has no effect o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com