Method for optimizing structure of annular water retention rate logging sensor array

A technology of sensor array and optimization method, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc., can solve the problem that the instrument cannot fully reflect the real situation in the downhole, achieve the effect of structural optimization and improve measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

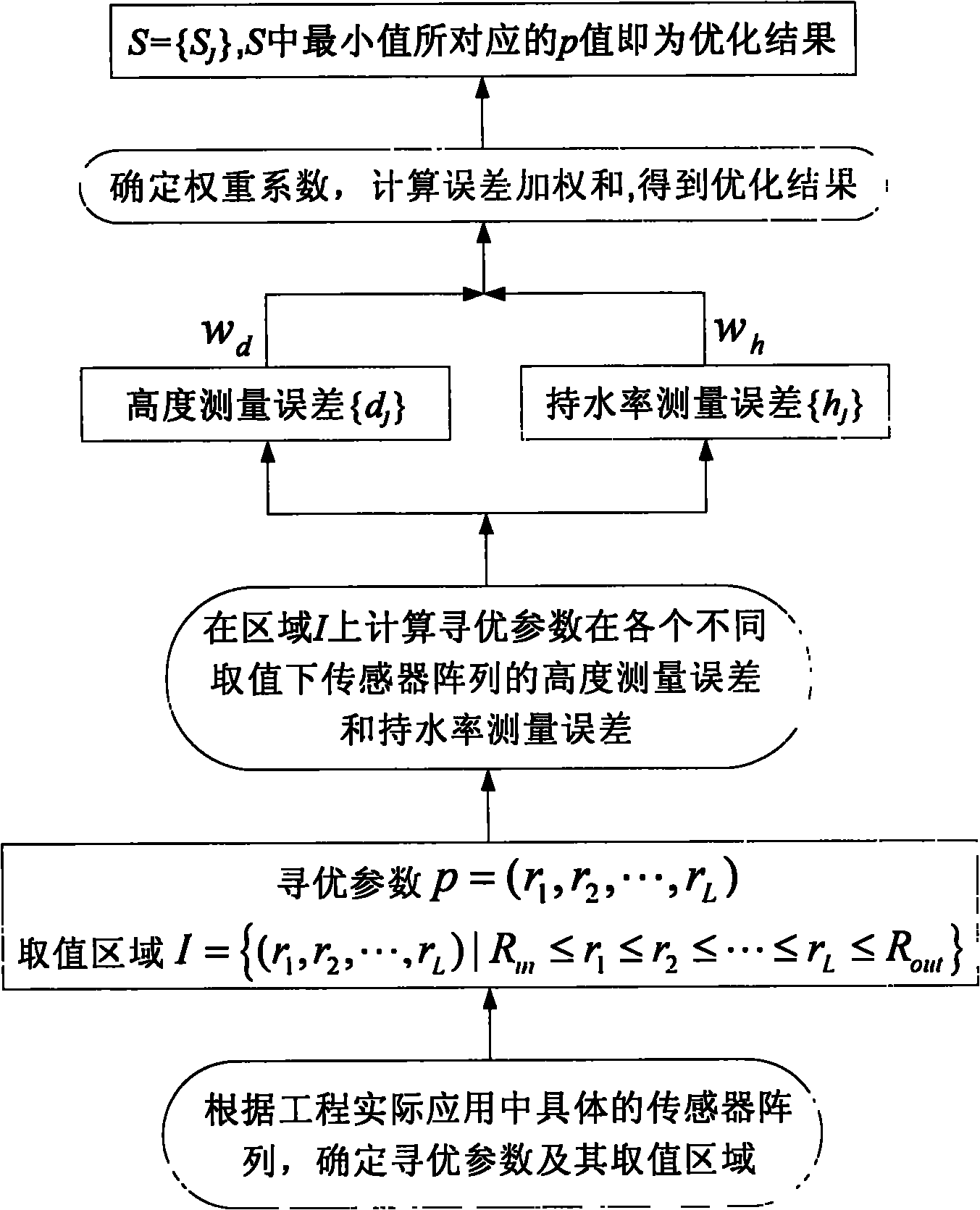

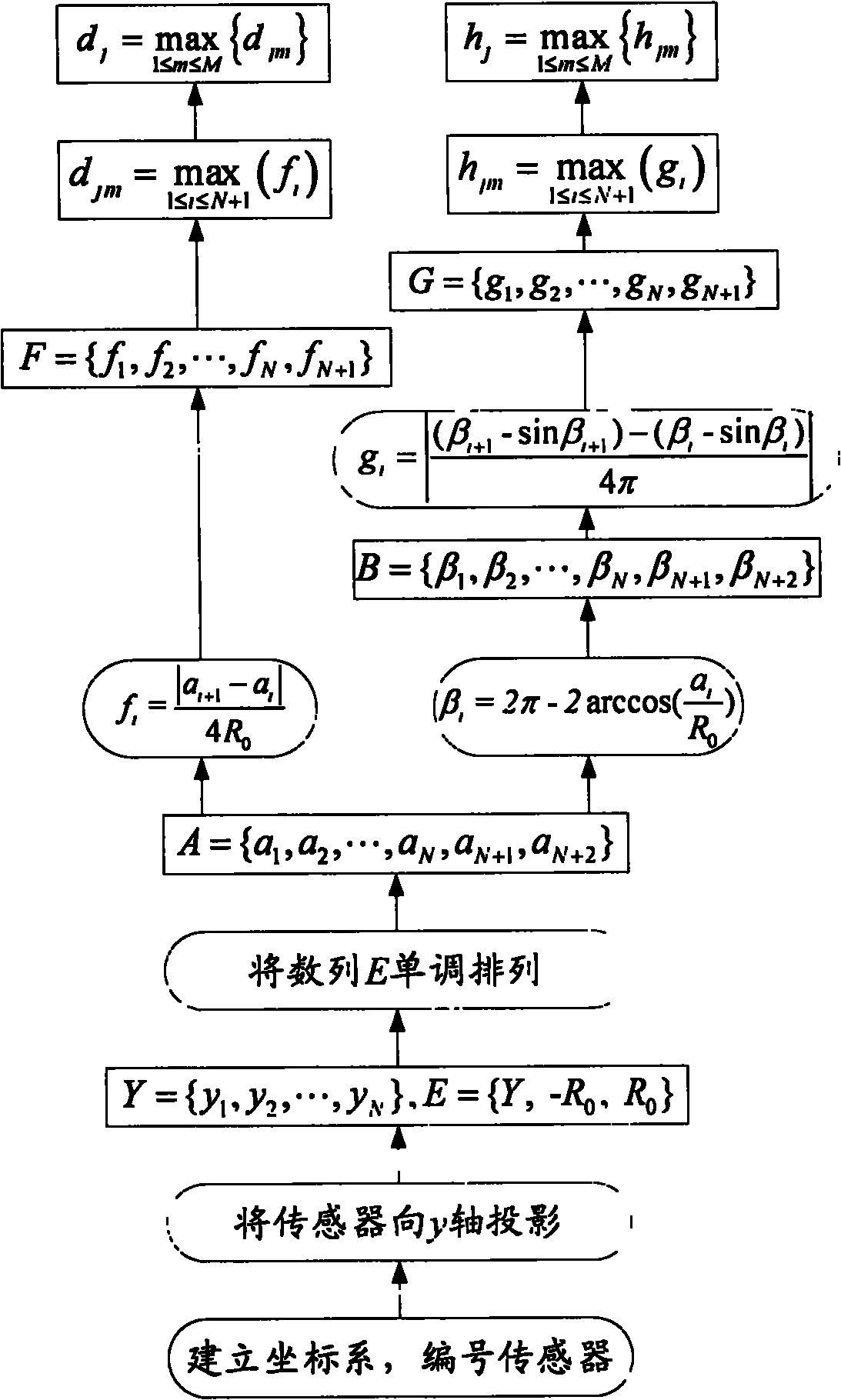

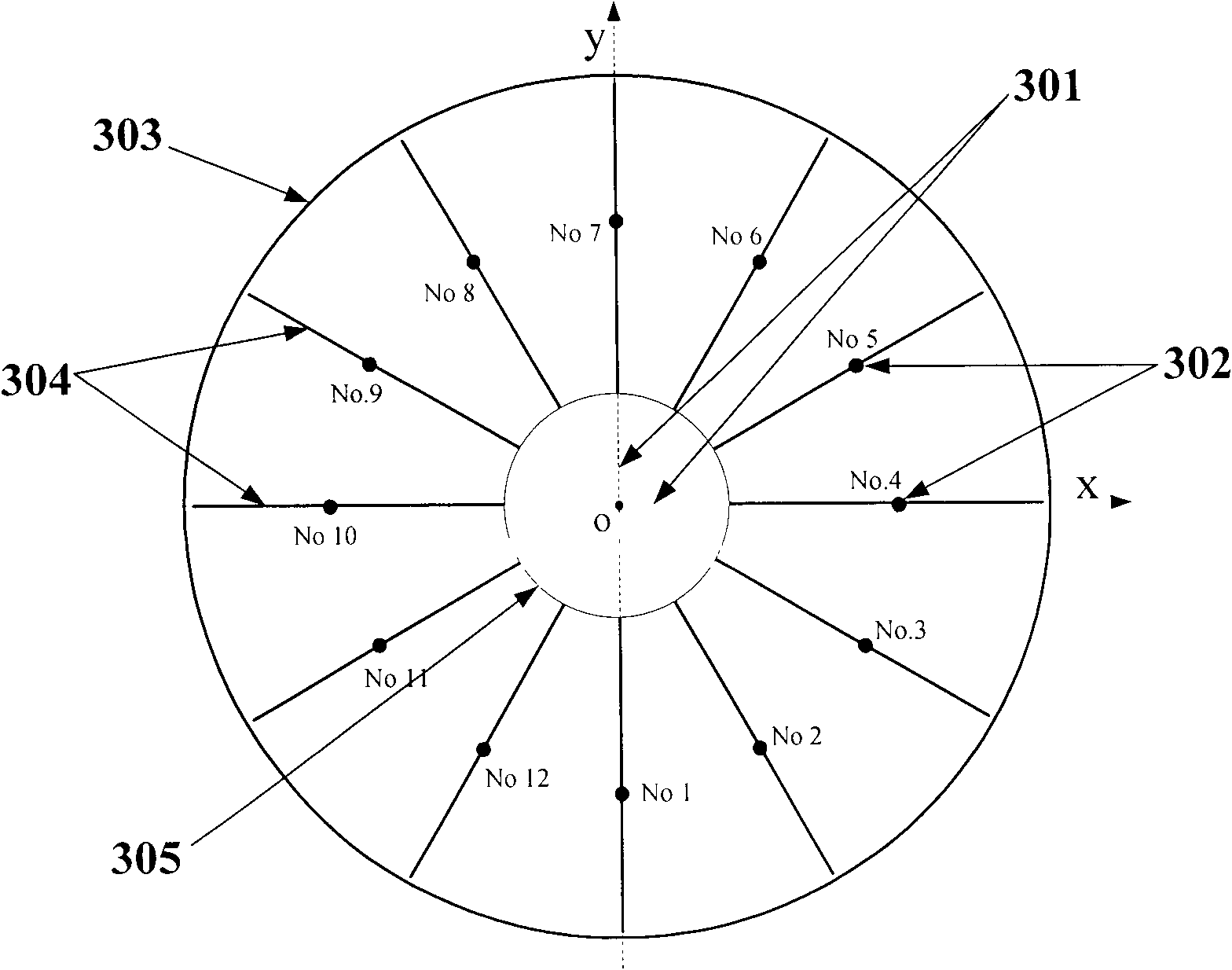

[0020] figure 1 It is a flow chart of the present invention, wherein the square frame with rounded corners represents the steps of the present invention, and the rectangular square frame represents its corresponding result; figure 2 It is a calculation flow chart of the error analysis method adopted when calculating the height measurement error and the water holdup measurement error in the present invention, wherein the square boxes with rounded corners represent the steps of the error analysis method, and the rectangular square boxes represent the corresponding results; image 3 It shows the sensor array part of a specific annular array water holdup logging tool and the cross-section of its measuring pipeline. The sensor array of the device has 12 measuring sensors (302) (conductivity probes), which are respectively installed in 12 etc. Angle distribution on the support arm (304). The support shaft (305) is located at the center of the pipeline and is coaxial with the pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com