Ventilation and forced air cooling device in LED (light emitting diode) bulb

A technology of LED light bulbs and heat sinks, which is applied in the electronic field and can solve the problems of insufficient heat dissipation of the light source, inability to meet the use of LED lamps, and failure of light bulbs to dissipate heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

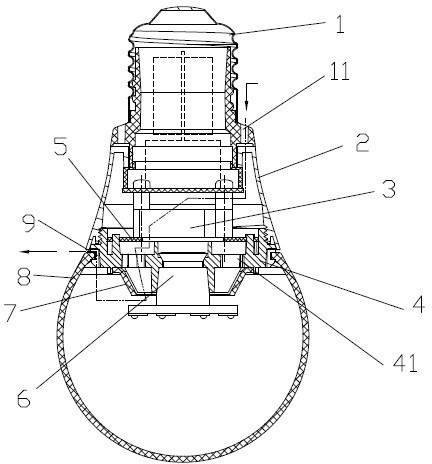

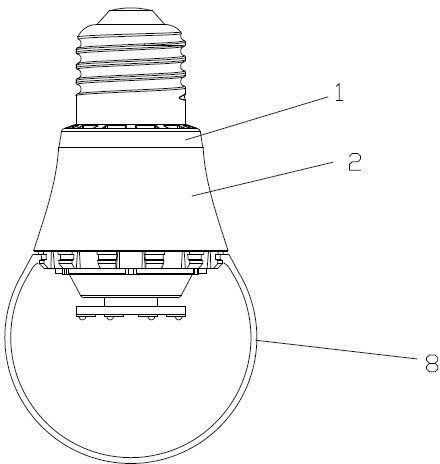

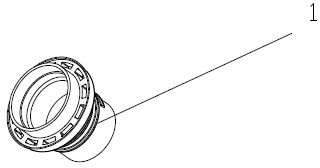

[0032] Such as figure 1 - Figure 13 The illustrated embodiment of the present invention, the forced ventilation cooling device inside the LED bulb, includes: Lamp base insulator 1: there is a vent 11 on it; lamp housing 2: clamped on the lamp base; micro fan 3: installed on the lamp Inside the shell; two-way radiator 4: set between the lamp shell and the lampshade, one end is clamped on the lamp body, the other end is matched with the lampshade, and the two-way radiator is provided with a through hole 41 to connect the lamp shell and the inner cavity of the lampshade; the current limiting plate 5: set in the lamp housing, covered above the two-way heat sink; heat conduction column 6: one end is clamped on the two-way heat sink, and the other end cooperates with the LED light-emitting element assembly; wind guide reflector 7: set in the lampshade, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com