Drying and humidifying integrated machine

An all-in-one drying technology, applied in heating methods, lighting and heating equipment, applications, etc., can solve the problems of shortened machine life, high power consumption, and small dehumidification, and achieve resource and space saving, convenient movement, and strong The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

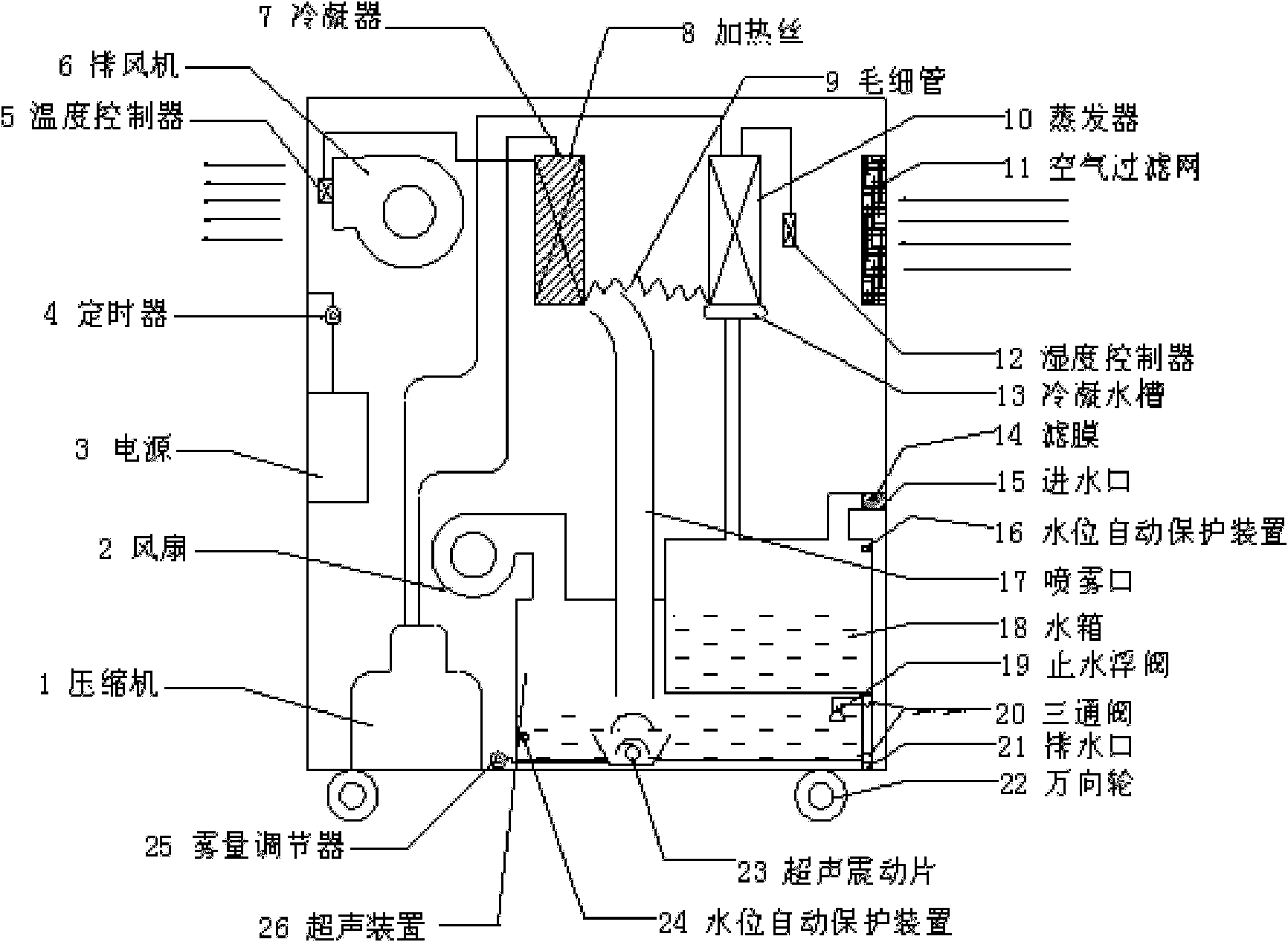

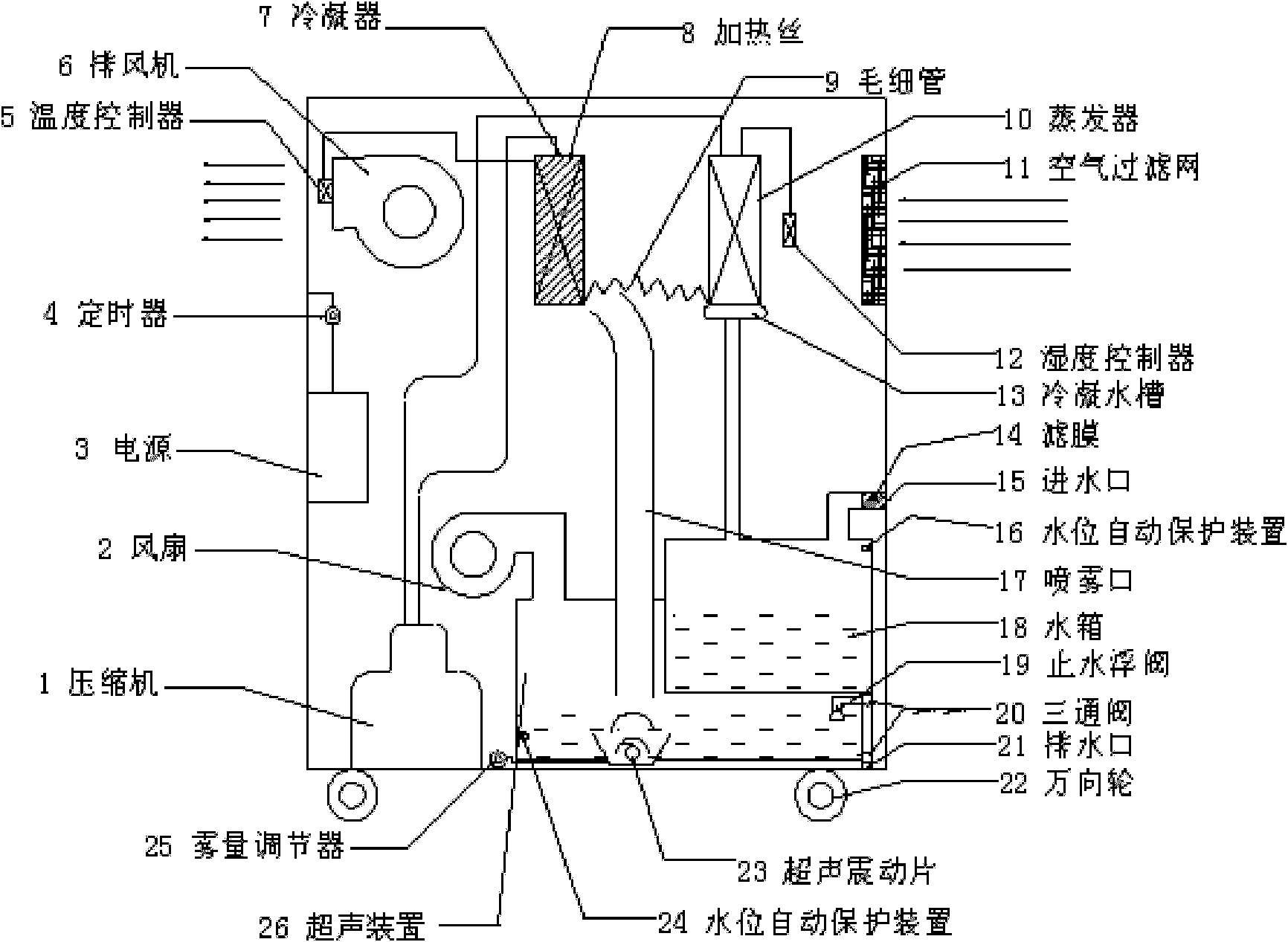

[0016] Such as figure 1 The drying and humidifying integrated machine shown is mainly composed of a compressor 1, a fan 2, a power supply 3, a timer 4, a temperature controller 5, an exhaust fan 6, a condenser 7, a heating wire 8, a capillary tube 9, an evaporator 10, Air filter 11, humidity controller 12, condensation water tank 13, filter membrane 14, water inlet 15, automatic water level protection device 16, spray port 17, water tank 18, water stop float valve 19, three-way valve 20, drain port 21, Universal wheel 22, ultrasonic vibrating sheet 23, automatic water level protection device 24, fog volume regulator 25, ultrasonic device 26, compressor 1, fan 2, exhaust fan 6, heating wire 8, ultrasonic vibrating sheet 23 powered by power supply 3 One end of the compressor 1 is connected to the evaporator 10, and the other end is connected to the condenser 7, and the evaporator 10 and the condenser 7 pass through the capillary tube 9 to form a circulation loop. The compressor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com