Hanging basket drying equipment for drying household porcelain

A drying equipment and daily-use technology, applied in progressive dryers, lighting and heating equipment, drying and other directions, can solve the problems of many process links, inability to achieve continuous production, unsatisfactory heating efficiency, etc., to reduce manufacturing the effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

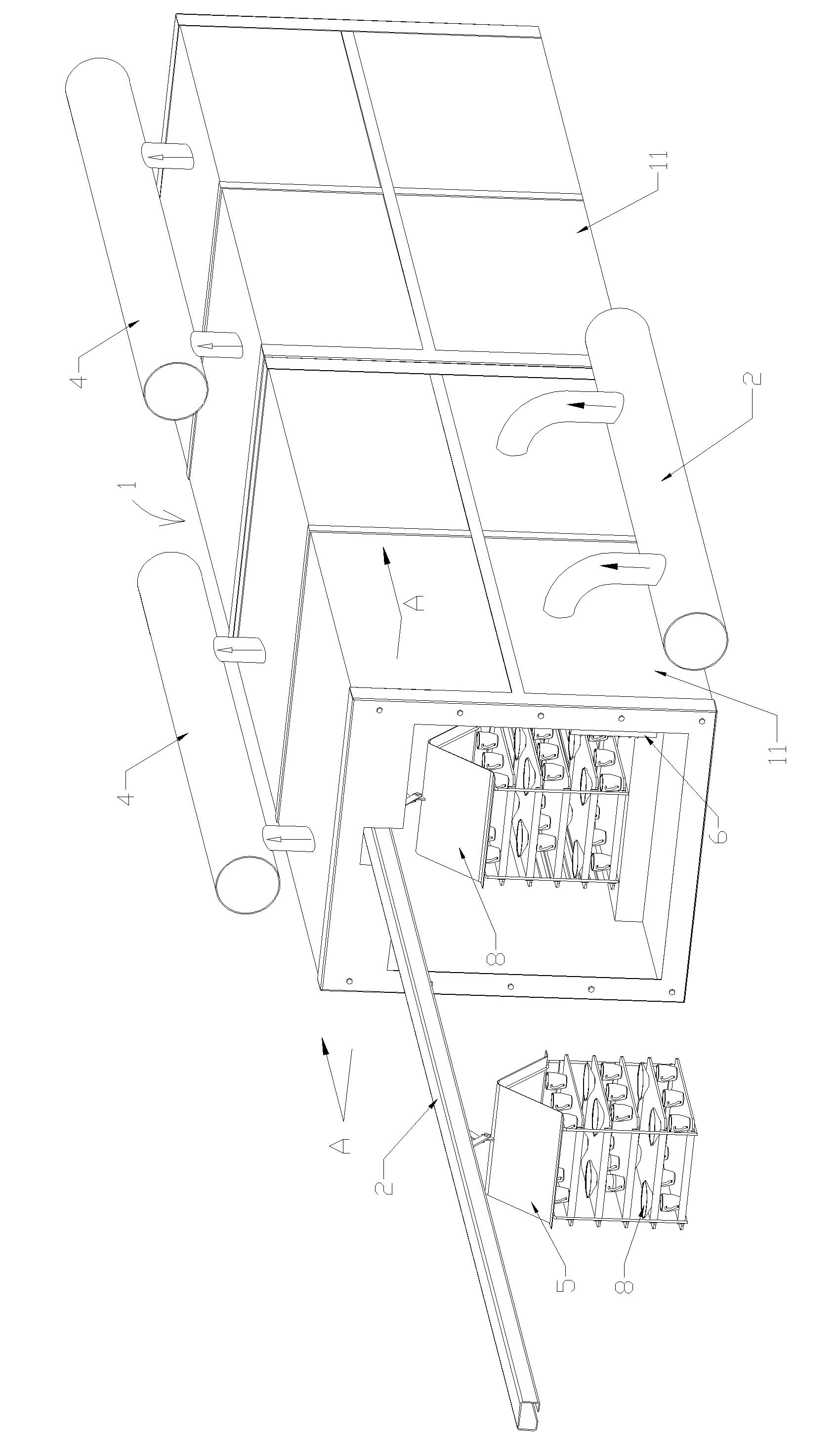

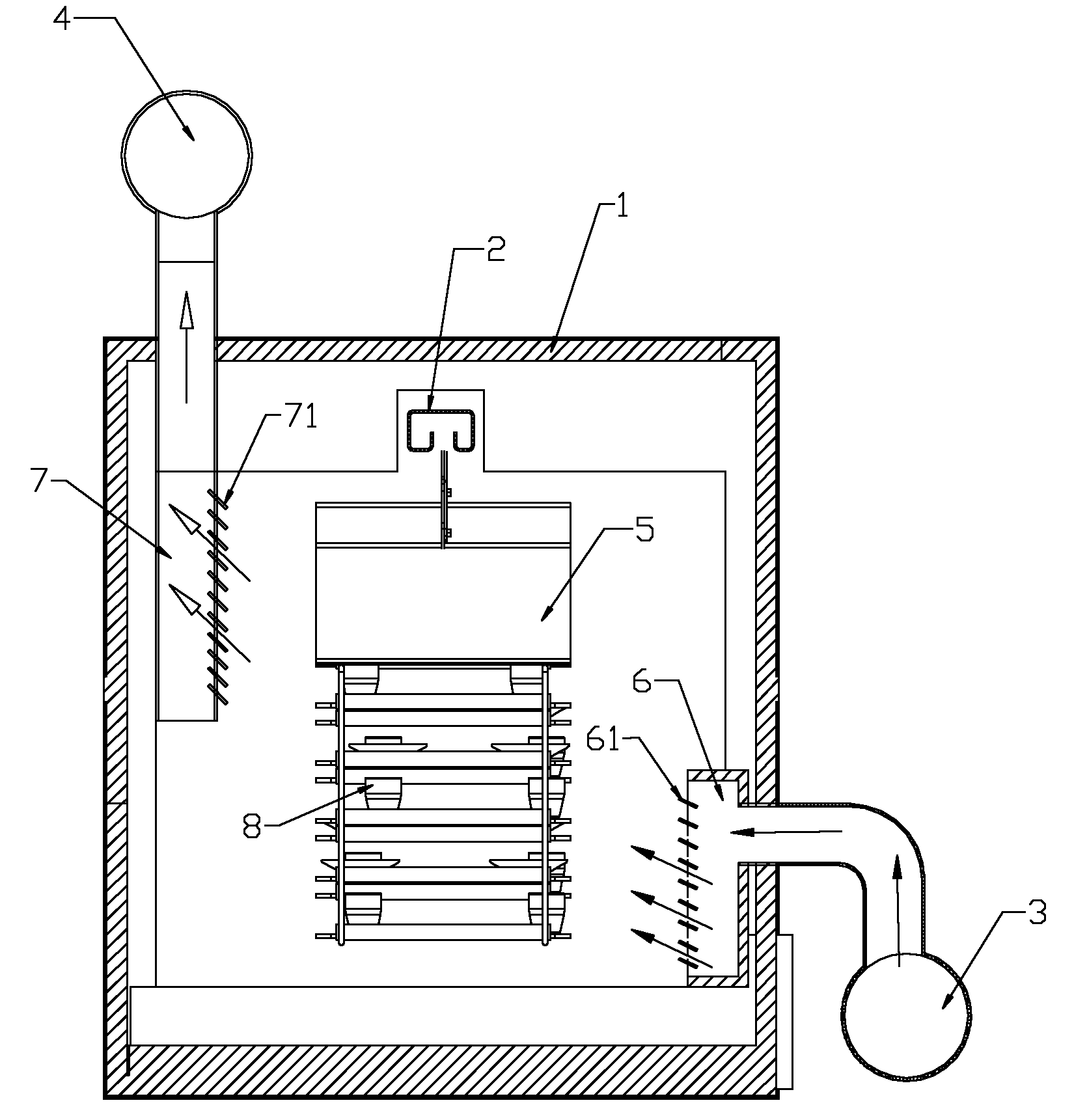

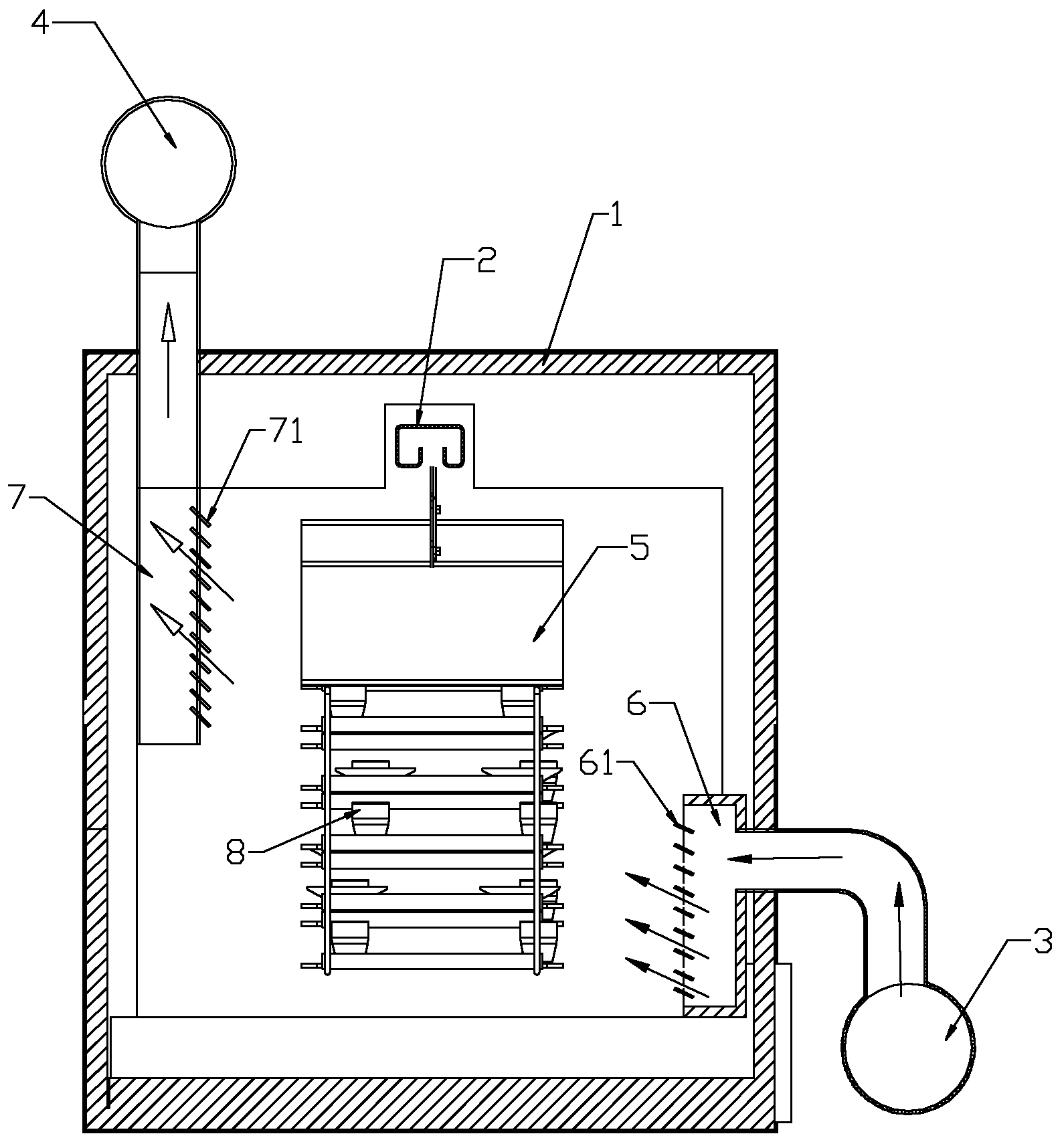

[0022] Such as Figure 1~2 The hanging basket drying equipment for daily porcelain drying shown is an embodiment of the present invention, and it includes a tubular main body 1 , rails 2 , heating main pipe 3 and dehumidification main pipe 4 .

[0023] The main body 1 includes a number of through cylindrical unit bodies 11. The open end faces of the plurality of unit bodies 11 are sequentially butted end to end to form a whole surrounded by four sides. The inner cavities of each unit body 11 are connected to form a drying chamber. The two outermost The openings on the non-butting end faces of the unit bodies form the inlet and outlet of the main body 1, and the lower side walls of each unit body 11 are provided with air inlets connecting the inner cavity with the outside world, and the top wall of each unit body 11 is far away from the inlet of the unit body. One side of the air outlet is provided with an air outlet connecting the inner cavity with the outside. The air inlets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com